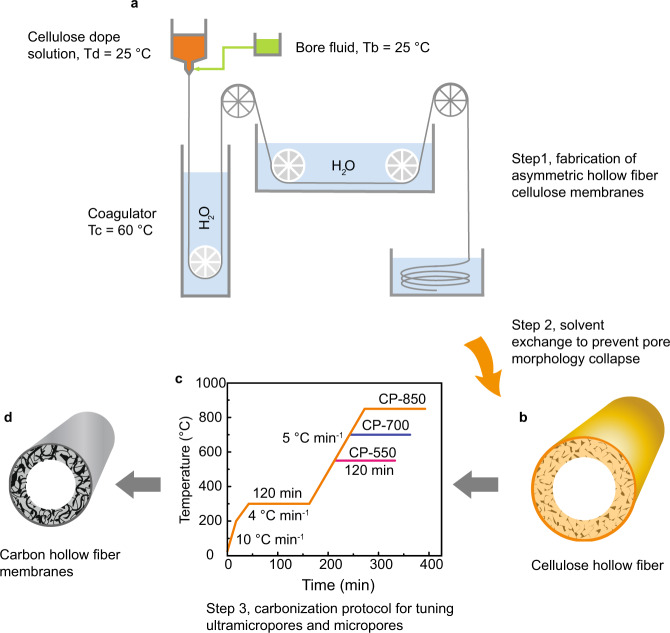

Fig. 1. Preparation of carbon hollow fiber membranes (CHFMs).

a Schematic of the fabrication process for asymmetric cellulose hollow fibers by the dry-wet spinning process with controlled spinning temperatures. Temperature of dope solution (Td), bore solution (Tb), and coagulator (Tc) are 25, 25, and 60 °C, respectively. b Schematic of dried cellulose hollow fiber precursors. c Carbonization protocols (CPs) for the fabrication of CHFMs. d Schematic of asymmetric CHFMs. The key step 1 is the fabrication of asymmetric cellulose hollow fibers by controlling the coagulation temperature at >45 °C (60 °C was used in this work); step 2 is non-solvent exchange using lower surface tension solvents (isopropanol, n-hexane) to remove residual water inside hollow fibers before drying to prevent pore morphology collapse; step 3 is tuning the ultramicropore and micropore structure of carbon membranes by changing the final carbonization temperature from 550 to 850 °C.