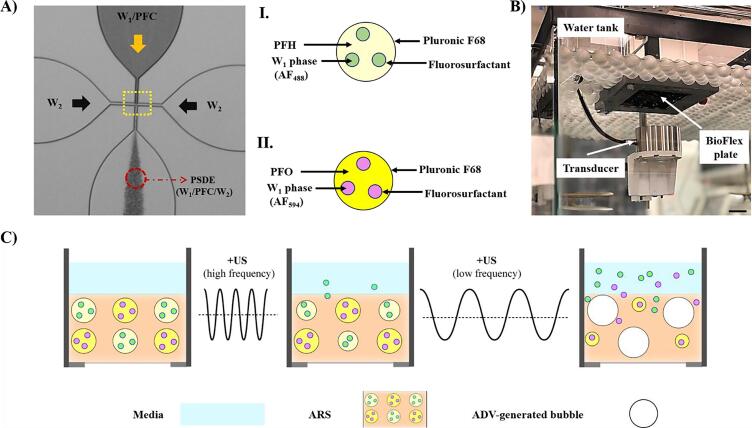

Fig. 1.

(A) An image of the microfluidic chip showing the flow focusing geometry of the junction (14 µm × 17 µm, highlighted in a yellow dotted box). The phase-shift double emulsion (PSDE) was generated by pumping the inner (W1/PFC) and outer (W2) fluids at 1 and 10 µL/min, respectively. The enlarged features display schematics of two similarly-sized PSDEs each containing a different PFC phase and payload: (I) perfluorohexane (PFH) and Alexa Fluor 488-labeled dextran (AF488), and (II) perfluorooctane (PFO) and Alexa Fluor 594-labeled dextran (AF594). (B) Picture of ultrasound (US) exposure setup. The plastic balls at the water surface maintain the temperature and dissolved gas concentration in the water tank. Acoustically-responsive scaffolds (ARSs), containing PSDEs, were polymerized in a BioFlex plate which was positioned on the surface of the water tank. US was applied through the silastic well bottom. (C) Schematics of side views of ARSs containing PFH-AF488 as well as PFO-AF594 exposed to different US parameters (i.e., frequency and pulse duration) resulting in different responses in PSDEs. Sequential release of AF488 and AF594 was achieved using high frequency US followed by low frequency US, respectively. Scale bar: 20 mm. (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)