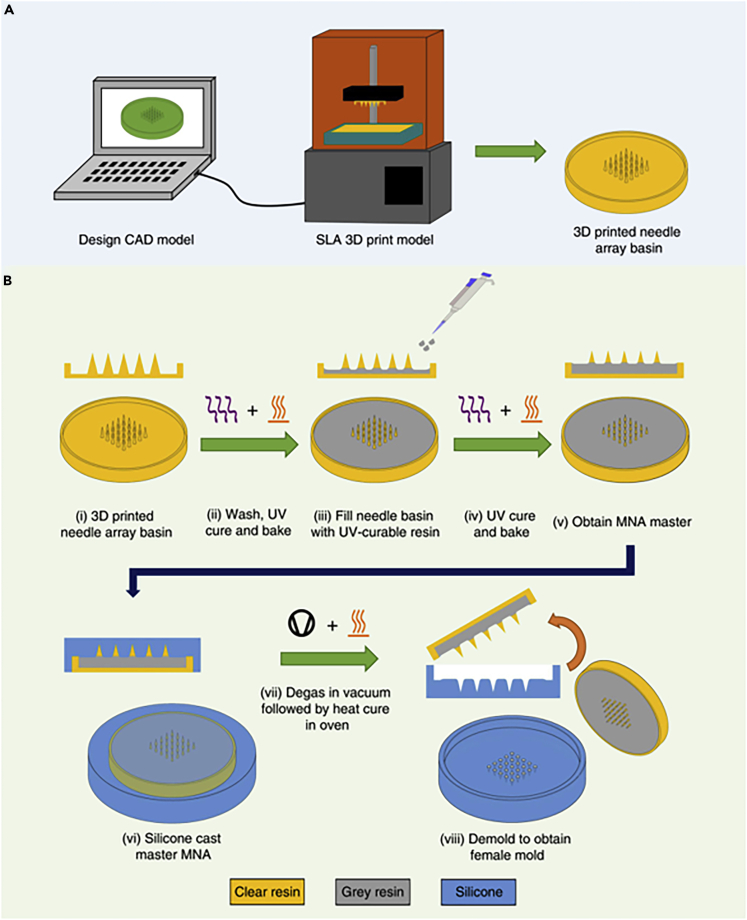

Figure 3.

Step-by-step illustration of fabricating microneedles (MNs) with stereolithography (SLA) 3D printing and replica mold method

(A) The design procedure was followed by 3D printing of the designed structure using an SLA printer.

(B) The 3D-printed MNs were washed and then cured with UV light, followed by filling the basin with UV-curable resin to obtain the desired MN height, resulting in a microneedle arrays (MNA) master. In the next step, using silicone, degassing by the vacuum chamber, and heat curing in the oven, the final female master mold can be produced (Krieger et al., 2019). Adapted with permission from (Krieger et al., 2019). Copyright 2019, Springer Nature.