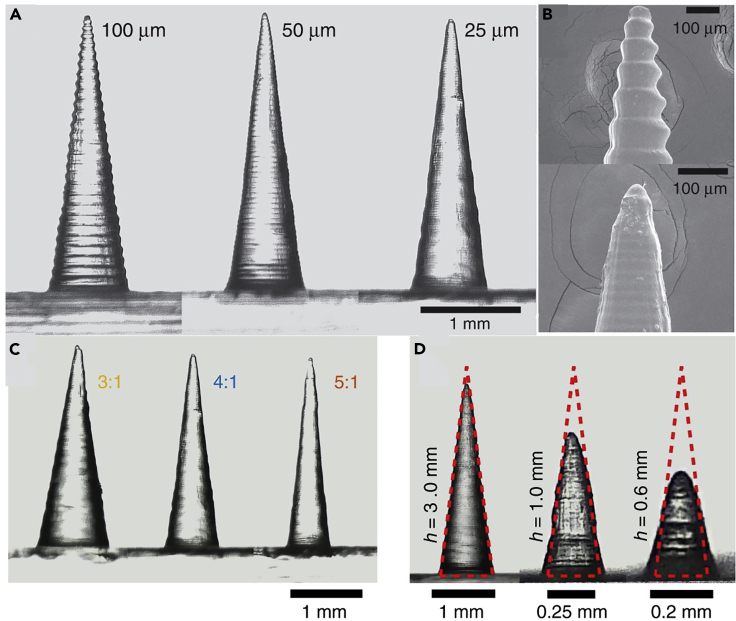

Figure 4.

Scanning electron microscope (SEM) images of microneedles (MNs), fabricated by stereolithography (SLA), with different feature sizes

(A) Fabricated MNs via various printing layer heights: 100, 50, and 25 micrometers. Although lower layer heights bring about better surface quality, the printing process will be slower. Hence, choosing the proper layer height is a trade-off between surface quality and time.

(B) Tip of fabricated MNs (top:100 μm, bottom: 25 μm layer height).

(C) Different aspect ratios. A higher aspect ratio here means a gradual increase of shaft thickness that results in a painless insertion of MN. However, thinner needles possess low mechanical strength that can result in breaking the needle in the insertion process.

(D) The discrepancy between the input and output height. Higher aspect ratios suffer more from discrepancy issues (Krieger et al., 2019). Adapted with permission from (Krieger et al., 2019). Copyright 2019, Springer Nature.