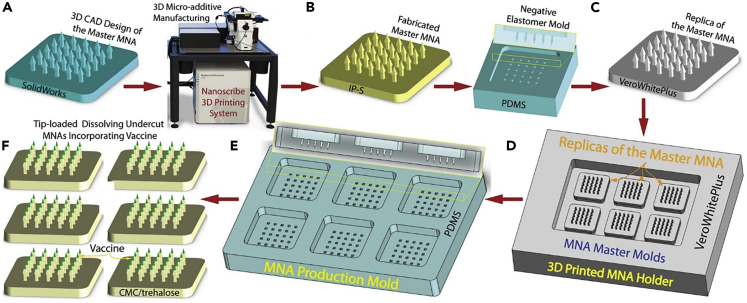

Figure 5.

Scalable microneedle array (MNA) fabrication in six steps, using 3D direct laser printing and molding

(A) 3D design of size features of the MNA, based on the proposed application.

(B) Direct production of designed MNA using 3D direct laser printing. MNs with a height of 750 μm, base diameter of 150 μm, arrow base radius of 250 μm, and a tip angle of 30° were produced.

(C) Replicating the master MNA mold with high fidelity by a two-step micromolding process.

(D) Arranging multiple MNA master molds on a 3D printed holder.

(E) Production of MNA fabrication molds by polydimethylsiloxane (PDMS).

(F) Loading the desired drug on the tip of the fabricated MNAs by a spin-casting method (Balmert et al., 2020). Adapted with permission from (Balmert et al., 2020). Copyright 2020, Elsevier.