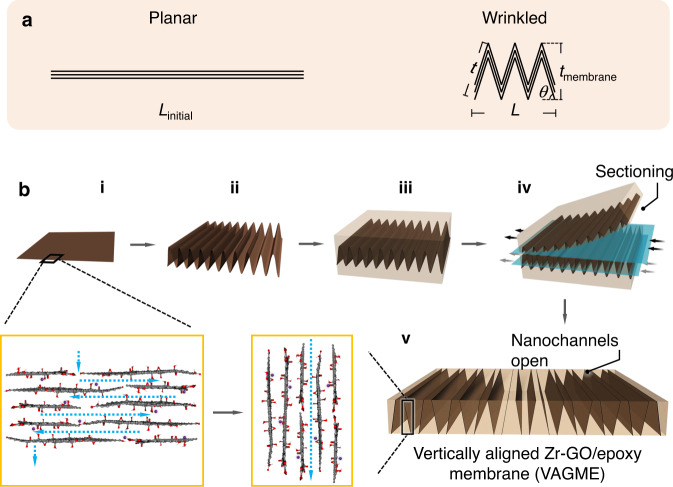

Fig. 1. Structure and fabrication steps leading to vertically aligned Zr-GO/epoxy membranes.

a Sketch of compressive film wrinkling. Side view of planar and 1D wrinkled films. Figure illustrates that wrinkling tilts the horizontal line into multiple near vertical line segments. b Fabrication steps leading to vertically aligned Zr-GO/epoxy membranes. i, Drying-induced assembly of Zr-GO nanosheets (Zr/C atomic ratio approximately 1/22) on pre-stretched polystyrene substrate (GO film thickness 1 μm). Inset: nanostructure of planar Zr-GO films with horizontal alignment and tortuous flow pathways. Brown strips represent 1 μm thick multilayer GO film segments. The light-yellow box represents the epoxy matrix. Purple spheres represent ZrO(II) cations (unhydrated state for reference). Fully hydrated ZrO(II) diameter is approximately 1 nm, implying that ZrO(II) likely exists in the interlayer spaces in a partially hydrated state complexed with O-containing groups on GO. ii, Wrinkled Zr-GO films are produced by thermally activated mechanical compression. iii, Wrinkled Zr-GO films are removed from the substrate and imbedded into epoxy resin. iv, Multiple cycles of microtome sectioning yield Zr-GO/epoxy composite membranes. v, Side view of vertically aligned Zr-GO/epoxy membrane (VAGME) with the entrances to interlayer nanochannels open at the top and bottom surface. This method transforms a single planar Zr-GO film into hundreds of vertical film segments, where each segment is an array of approximately 1000 GO interlayer nanochannels aligned with a strong Z-directional component.