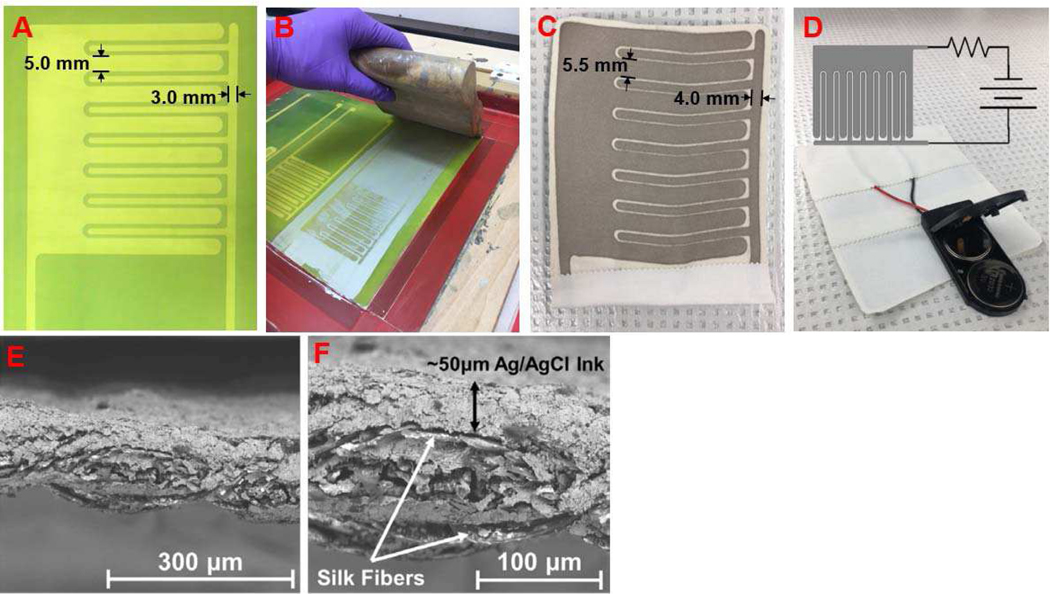

Fig. 1.

(a) The screen with developed pattern for screen printing the PED electrodes. (b) The Ag/AgCl ink was spread over the screen mesh and manually printed using a squeegee. (c) The resultant printed design on the silk substrate with actual dimensions as marked due to ink spreading on porous substrate. (d) The printed electrodes were connected to the battery pack with two 3V batteries in series and a current limiting resistor. The open electrical connections were isolated by medical tape. Overlaid is a schematic for the working circuit diagram. (e) An scanning electron microscopy (SEM) image of the Ag/AgCl ink printed onto the silk fabric. (f) SEM image of the fabric-electrode cross-section shows the ink is absorbed within the fabric with a ∼50 μm ink layer on the silk fabric.