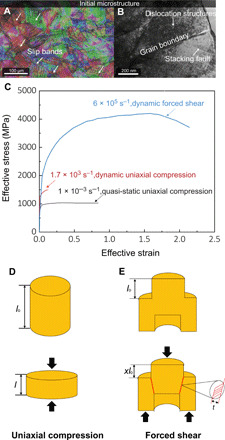

Fig. 1. Initial microstructure, mechanical response, and schematic sample geometry of the as-swaged CrMnFeCoNi HEA.

(A) EBSD map of the initial microstructure (with inverse pole figure) showing deformed grains with a grain size of ~100 μm. (B) TEM micrograph of the as-swaged sample showing a high density of dislocation structures. Note that in both EBSD and TEM characterizations, only very few deformation twins can be observed. This may be attributed to the unique straining pathway of swaging process, which does not favor stress buildup for the activation of twinning. (C) Mechanical response, expressed as equivalent stress versus equivalent strain of the as-swaged CrMnFeCoNi HEA subjected to uniaxial quasi-static compression (), high strain-rate compression (), and dynamic shear (). (D and E) Schematic illustrations of the cylindrical and hat-shaped samples, respectively.