Abstract

Metals and alloys, including stainless steel, titanium and its alloys, cobalt alloys, and other metals and alloys have been widely used clinically as implant materials, but implant-related infection or inflammation is still one of the main causes of implantation failure. The bacterial infection or inflammation that seriously threatens human health has already become a worldwide complaint. Antibacterial metals and alloys recently have attracted wide attention for their long-term stable antibacterial ability, good mechanical properties and good biocompatibility in vitro and in vivo. In this review, common antibacterial alloying elements, antibacterial standards and testing methods were introduced. Recent developments in the design and manufacturing of antibacterial metal alloys containing various antibacterial agents were described in detail, including antibacterial stainless steel, antibacterial titanium alloy, antibacterial zinc and alloy, antibacterial magnesium and alloy, antibacterial cobalt alloy, and other antibacterial metals and alloys. Researches on the antibacterial properties, mechanical properties, corrosion resistance and biocompatibility of antibacterial metals and alloys have been summarized in detail for the first time. It is hoped that this review could help researchers understand the development of antibacterial alloys in a timely manner, thereby could promote the development of antibacterial metal alloys and the clinical application.

Keywords: Antibacterial metals and alloys, Antibacterial alloying elements, Antibacterial stainless steel, Antibacterial titanium alloy, Antibacterial magnesium alloy

Graphical abstract

Highlights

-

•

This paper focuses the recent development of several antibacterial metals and alloys as biomedical materials.

-

•

The possible antibacterial mechanisms of antibacterial metals and alloys are summarized in this paper.

-

•

This review discusses the feasibility of antibacterial metals and alloys as biomedical implants in the future.

1. Introduction

Metals and alloys, including stainless steel, titanium and its alloys and cobalt alloys, have been widely used clinically due to their high strength, good wear resistance, good corrosion resistance, high fatigue properties and good biocompatibility, such as dental implants, hip and knee replacements, bone plates and screws. It was reported that up to 2.5 million dollars medical devices were made of metals and alloys.

The medical devices greatly improve the life quality of patients, but the device related infection or inflammation is still a main complaint despite strict antiseptic operating procedures, including systemic prophylaxis. It was reported that surgical site infection represents the most common nosocomial infection, accounting for 15% of all nosocomial infections [1]. Oral permucosal implants pose a very high risk of infection, as they breach the epithelial barrier and are thereby permanently exposed to the oral microflora. It was reported that 90% of all implants showed signs of inflammation and 50% of all implants showed signs of irreversible tissue destruction [2]. Nevertheless, the ten-year survival rates of endosseus implants were reported to be around 90–96% [2]. For dental implants, the most frequent cause of failure of dental implants is peri-implant inflammatory diseases such as peri-implantitis, which normally causes a circumferential bone loss and in turn may compromise the longevity of an implant. An analysis based on 11 studies showed a mean prevalence of peri-implantitis of 22% and a positive relationship between insertion time and prevalence [3] in which 5–11% of dental implants failed and must be removed [4]. Peri-implantitis affected about 10% of implants and 20% of patients during a 5–10 year observation period after implant placement [5]. For orthopedic replacement, with sterile operation and perioperative antibiotic defenses, the risk of infection after internal fixation ranged between 0.4% and 16.1% depending on the extent of fracture [6,7]. To be more precise, the infection rates of periprosthetic joint infections were 0.5%–2% [8], 2%–9% [9], and 0.3%–1.7% [10] after total joint replacement of the knee, hip and ankle, respectively.

The bacterial infection or inflammation that seriously threatens human health has already become a worldwide complaining issue [11]. So research on antibacterial technologies [12], including mechanical clearance, surface modification [13] and antibacterial materials is urgently necessary. Taking dental implants for example, the biofilm has to be removed mechanically, which should not change the micromorphology of the implant surface. Mechanical in vitro and in vivo treatments with an air powder abrasion device or with a titanium brush left around 10% bacterial residues on rough sand blasted titanium surfaces [14,15]. Surface modification can effectively prohibit the biofilm formation on the implant materials, such as developing a surface which causes cell damage to the adhered bacteria or anti-adhesive properties that inhibits bacterial adhesion in the first place. Various approaches have been used to convert the surfaces of biomedical devices into antimicrobial surfaces and lately reviews have been published on these approaches [4].

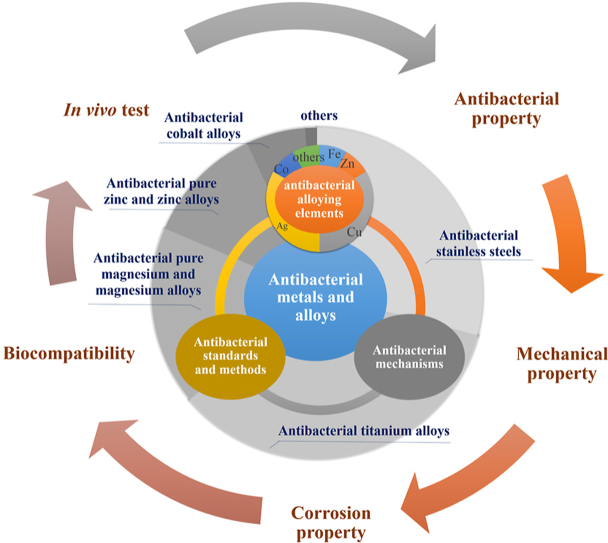

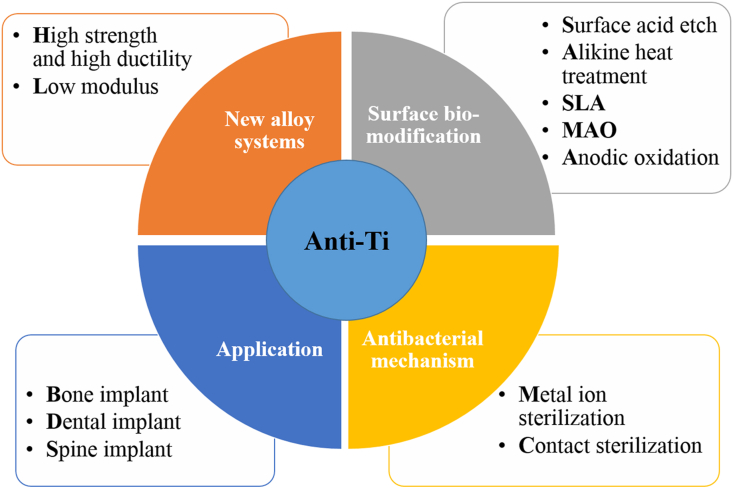

Antibacterial metals and alloys are a kind of metallic materials, which exhibits strong ability to inhibit the adhesion, the growth and the proliferation of a bacterium by element alloying and proper metal forming and heat treatment. Recently, Cu- and Ag-containing antibacterial metal alloys have been reported to exhibit good antibacterial ability against lots of bacteria, such as antibacterial stainless steel [16], antibacterial titanium [17,18], antibacterial magnesium and alloys [19] and antibacterial cobalt alloy [20,21]. The alloying elements mainly are Ag and Cu elements, which have been reported to have broad spectrum antibacterial ability. Nowadays, antibacterial metal alloys have attracted much attention worldwide and lots of new progresses have been achieved, which will promote the clinical application of antibacterial metal alloys. Fig. 1 shows the publication numbers on antibacterial or antimicrobial research searched by Web of Science. There are about 56,000 publications on this area in the past two decades with a 6–16% increase in the past decade. But research on “Antibacterial Metal” shows a much higher increase, especially on “Antibacterial Titanium”, which even increased by as much as 40% in 2016.

Fig. 1.

Publications on antibacterial research searched by Web of Science. a) key words: antibacterial or antimicrobial in topic, b) keywords: antibacterial metal, antibacterial steel and antibacterial titanium in topic. (Updated at 2020-05-21).

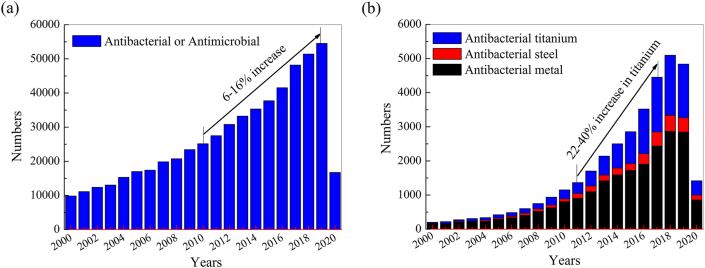

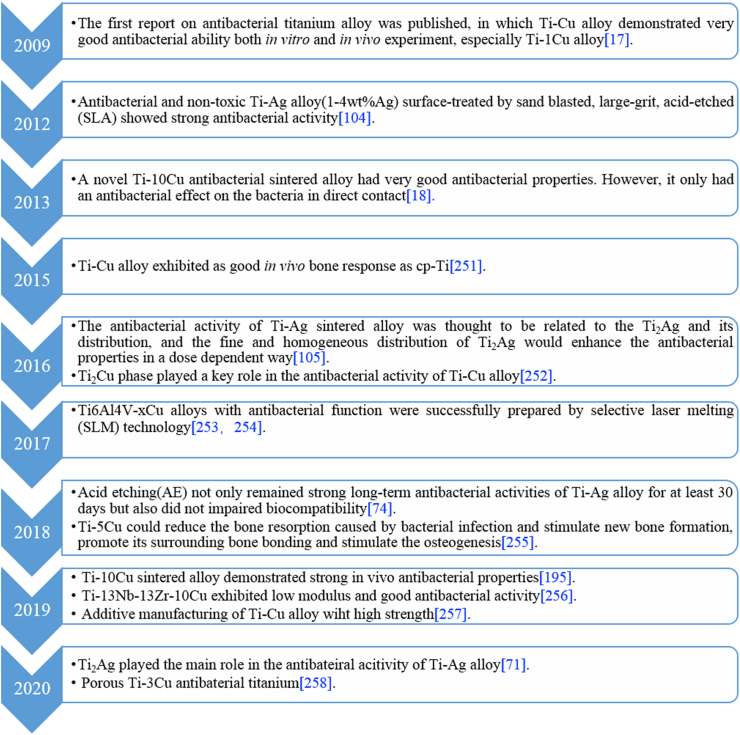

This paper summarizes the recent research results on antibacterial metals and alloys for the first time and Fig. 2 overviews the main framework of this review. It is hoped this review could benefit the flourishing development of antibacterial metals and metal alloys.

Fig. 2.

The main framework of this review.

2. Interaction between bacterium and metal alloy

In order to develop antibacterial metals and alloys, it is very necessary to understand the interaction between a bacterium and materials. The interaction between a bacterium and materials, such as metallic materials can be roughly divided into four steps:

-

1)

The primary step is the bacterial adhesion to a material surface. As pointed out by Campoccia [12], bacterial adhesion on materials surfaces is critically influenced by numerous variables, including the type of pathogen, the nature of physiological fluids, the surface morphometry and the surface physico-chemical properties of materials. The bacterial adhesion process is reversible.

-

2)

The secondary step is the colonization of the bacterium on the material surface. During this process, bacteria accumulate on the surface and colonize. The colonization is influenced by specific molecular and cellular interaction (adhesion proteins, proteinaceous appendages and extracellular polymeric substance production) [22]. On the other hand, bacterial colonization also changes the surface chemistry of the substrate by virtue of its metabolic byproducts. This process is irreversible.

-

3)

The third step is the biofilm formation and maturation. When bacteria colonize on the surface, bacterial microcolonies will form and bacteria will produce exopolymeric substances (mainly polysaccharides and other macromolecules), which contribute to biofilm formation. Once a biofilm is formed on the surface, it will protect bacteria in self-produced polysaccharidic matrix from both fluid shear stress and the action of systemic pharmacological therapies [22].

-

4)

The final step is the proliferation of bacteria. With the protection of the biofilm, bacteria begin to proliferate on the surface. As a result, the whole surface will be covered by bacteria.

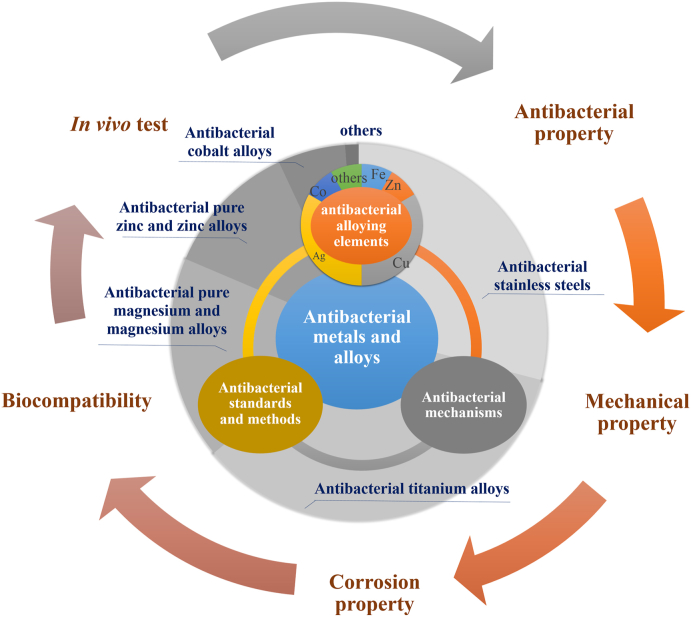

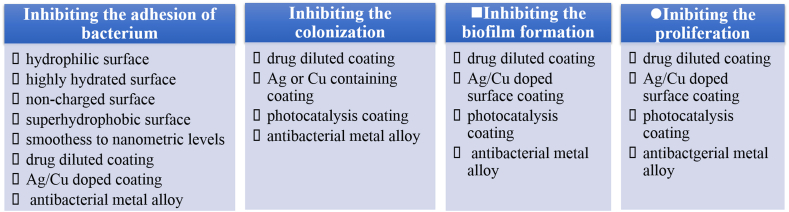

From the interaction between a bacterium and materials, it can be easily deduced that the strategies to reduce bacteria can be also roughly divided into four steps corresponding to the above four-step interaction, as shown in Fig. 3:

-

1)

Strategies to inhibit the adhesion of a bacterium on a metal surface, or anti-adhesion.

-

2)

Strategies to inhibit the colonization of a bacterium on a metal surface, or anti-colonization.

-

3)

Strategies to inhibit the biofilm formation on a metal surface, or anti-biofilm.

-

4)

Strategies to inhibit the proliferation of a bacterium on a metal surface, or anti-proliferation.

Fig. 3.

Antibacterial Strategies for metal alloys.

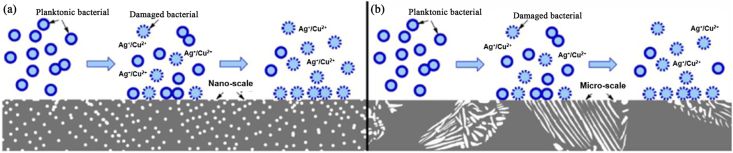

As stated above, the biofilm will protect the bacteria from external adversity. Therefore, the strategies mainly focus on the inhibition of the bacterium adhesion, the colonization and the biofilm formation. Lots of factors affect the bacteria adhesion, including the surface morphometry and physical-chemical properties of materials, environmental conditions as well as pathogen. Many surface technologies have been developed to change the surface properties, such as polymer coating, drug-eluting coating and charged surface [12]. Low adhesiveness of antifouling surfaces could possibly hinder tissue adhesion and integration of the implant. Nanostructure surface topography can determine a different bacterial behavior not just in terms of adhesion, but also in terms of cell metabolism, finally resulting bioactive. Smoothness down to nanometric levels was found to be associated in vitro to the lowest adhesion of both Gram-positive and Gram-negative bacteria [23].

It has been demonstrated that Ag- or Cu-containing surface coatings could resist the cell adhesion, the colonization as well as the biofilm formation due to the metal ion release [22,[24], [25], [26], [27], [28], [29], [30], [31]]. Recently, researches on antibacterial metal alloys also indicated that Cu- and Ag-containing metal alloys also show anti-adhesion and anti-biofilm function due to the metal ion release [32,33].

3. Advantages and disadvantage of antibacterial metals and alloys

Antibacterial surface modifications on metal could provide strong antibacterial ability but also good biocompatibility, including but not limited to the following measurements:

-

1)

Antibacterial metal-implanted surfaces, including silver-containing (particle or ion) [[34], [35], [36], [37]] and Cu-containing [[38], [39], [40]] or Zn-containing [[41], [42], [43]] antibacterial surface.

-

2)

Nanoscale surfaces, including Ag-containing nanoparticle (NPs) [44], Cu-containing NPs [45] or Zn-containing NPs [[46], [47], [48]], gold-containing [49] surfaces due to the strong antibacterial property of metal nanoparticle (NP), even if confronts against drug-resistant bacteria [50,51].

-

3)

UV-activatable or photo-sensitive antibacterial surfaces. Ti2O coating becomes bactericidal under near ultraviolet light. It was reported that these surfaces require up to 80 min of UV exposure to eliminate 75–95% of bacteria [4,52]. However, it is unclear if the technology would be effective on osseointegrated implants or in deep peri-implant pockets due to limitations in the penetration of light. Recently, it has been discovered that TiO2 nanostructures could produce superior antibacterial activity in vitro and in vivo under the irradiation of 808 nm near-infrared (NIR) light that human body can withstand for a short time [53]. Wu [[54], [55], [56]] reported some novel coatings, such as red phosphorus/IR780/arginine-glycine-aspartic acid-cysteine, polydopamine/IR780@MnO2 and red phosphorus/graphene oxide film on titanium implants utilizing NIR light, exhibiting excellent antibacterial property. Meanwhile, other photo-sensitive materials, such as hydrogels [57] and chitosan/Ag/MoS2 [58], have also used to prepare antibacterial surfaces.

-

4)

Drug-loaded surfaces. The drugs include conventional antibiotics such as amoxicillin [59], vancomycin [[60], [61], [62]], gentamicin [63], tetracycline [64], minocycline [59,65], cephalotin [66] and chlorhexidine [59,67].

-

5)

Antibacterial peptide surfaces (AMPs). Compared with antibiotics, AMPs have drawn increasing attention as novel antibacterial agents to combat bacterial invasion due to their special mechanisms of action, non-inducible bacterial resistance and lack of detrimental effects on humans [[68], [69], [70]].

However, on the other hand, there are some potential disadvantages in the antibacterial surface modification:

-

1)

The risk of bacterial resistance and cell toxicity.

-

2)

Finite duration of antimicrobial activity.

-

3)

Coating delaminating on implants.

In comparison with the antibacterial coatings, the antibacterial metals and alloys are of following advantages:

-

1)

Long-term antibacterial ability. The whole alloy is of antibacterial activity, thus the antibacterial ability will not be lost due to the machining, implantation, wear or abrasion, corrosion, etc. On the contrary, wear, abrasion or machining will produce a fresh surface, which in turn enhances the antibacterial activity. But for antibacterial coating, including Ag- and Cu-containing coating, wear or abrasion will destroy the coating and significantly reduce the antibacterial efficiency.

-

2)

Easy control and easy preparation. Normal metal and alloy processing, including casting, metal forming and powder metallurgy, etc. can be used to prepare and produce antibacterial metals and alloys with different shapes including bar, sheet and even complex structure. The metal and alloy can also be machined to produce implants with complex structure without reduction of antibacterial properties. Normal sterilization treatments also can be used on the antibacterial metal and alloy devices without reduction of antibacterial properties.

-

3)

No potential drug-resistance. The antibacterial ability of the metals and alloys is mainly attributed the antibacterial mechanism of alloying element, such as Ag, Cu and Zn elements which have been proven to have broad spectrum antibacterial ability to nearly all bacteria and no drug-resistance has been reported so far. More recently, it was demonstrated that the antibacterial properties were mainly controlled by the precipitation of Ag-or Cu-containing phase rather than the Ag or Cu ion release [71].

However, there are also some drawbacks of antibacterial metals and alloys:

-

1)

Mechanical properties and corrosion property. Ag and Cu are not main alloying elements for antibacterial stainless steel, titanium alloy and magnesium alloy. The addition of these antibacterial elements will change the microstructure characteristic, and thus change the mechanical properties potentially as well as corrosion resistance. For example, Cu element is considered as one of impurity elements for magnesium alloy, which can significantly deteriorate the corrosion resistance or accelerate the degradation of magnesium alloy [72]. Optimization of the mechanical property, the corrosion resistance and the antibacterial ability of antibacterial alloys will be a big challenge. Especially for long-term application, the effect of the antibacterial alloying elements on the fatigue strength will be significantly important.

-

2)

Potential toxicity of the metal ion release. It has been widely accepted that antibacterial ability of metals and alloys comes mainly from the released metal ions, including Ag+, Cu2+ and Zn2+. In order to obtain high antibacterial activity, metal ion release concentration has to be high enough, which might cause local toxicity and sometimes accumulation in distant target organs. Thus, it is always critical to find out a correct balance between bactericidal effects and biocompatibility properties, especially as far as cytotoxicity, cytocompatibility and immunocompatibility are concerned. However, it has been shown recently that titanium alloys with low Ag ion and Cu ion release also exhibited strong antibacterial ability, which reduces the toxicity of metal ions.

-

3)

Function of surface modification. For biomedical application, the metal surface is normally modified by surface coatings technology, such as bone morphogenetic protein (BMP) containing coating, to improve the surface cell bioactivity. Some surface coatings separate the bacteria from antibacterial metal alloy, and reduce or eliminate the antibacterial property as a result. However, sand blasting, sandblasting and acid etch (SLA), alkaline and heat treatment and micro-arc oxidation (MAO) have been proven to have no influence on the antibacterial activity of antibacterial titanium [[73], [74], [75], [76]].

4. Selection of antibacterial alloying element

Antibacterial agents can be broadly classified into three major categories: organic, inorganic and natural. To develop antibacterial metal alloys, the selection of antibacterial alloying elements is very important. So far, it is widely accepted that Ag and Cu are normally alloying elements in the development of antibacterial metal alloys, in which Ag has been described as one of the earliest materials to be intentionally used in surgery for its bactericidal properties [77]. Actually, other metals also exhibit antibacterial property to some extent.

Sreekumari et al. [78] reported the ability of different metals to resist bacterial attachment, including Zn, Ni, Pb, Co, Mo, Zr, Cu, Sn and Ti. Except Sn and Ti, all other metals showed profound antibacterial property against E. coli and S. aureus by reducing the bacteria colony forming units (CFU) on their surface to less than 101 from 106 within a period of 24 h. It was also reported that Pb followed by Co and Cu were most effective metals those resisted bacterial attachment and growth by causing mortality [78].

Kawakami [79] assessed the antibacterial property of 21 metallic elements against E. coli and S. aureus by a plate counting method. Besides Ag, Cu and Zn, other elements, including Al, Co, Ni, Mo, Pd and W also exhibited antimicrobial activity (R > 2.0) against both E. coli and S. aureus, and Pt and Pb only against E. coli, and V and Zr only against S. aureus. In addition, the bactericidal efficiency (K value) of Ag and Cu was significantly higher than the values of other metals, indicating strong biocidal activities of Ag and Cu.

Miyano [80] also evaluated the antibacterial ability of some pure metals by two different methods: plate count method and shaking flask method (JIS Z2802:2000). The plate count method results after 24 h incubation indicated that pure Co, Ni, Cu, Zn, Zr, Mo and Pb exhibited strong antibacterial ability (more than 2log10 reduction in total viable cell, cfu/mL) against S. aureus and Ti, Co, Ni, Cu, Zn, Zr, Mo and Pb showed strong antibacterial ability (more than 2log10 reduction in total viable cell, cfu/ml) against E. coli. On the contrary, the shaking flask test after 24 h incubation indicated that only Pb showed strong antibacterial ability against S. aureus and Zn and Co against E. coli. In addition, their plate count results indicated the antibacterial efficiency was in the following order from high to low: Pb > Cu > Co > Zn > Ni > Zr > Mo.

Heidenau et al. [81] evaluated the antibacterial ability of several metal ions against S. epidermis by the plate count method. Their results confirmed that Hg+, Ag+ and Cu2+ exhibited very strong antibacterial property but Co2+ and Zn2+ exhibited no significant antibacterial effect at the investigated concentrations. Table 1 summaries the minimum inhibitory concentration (MIC) of several metal ions for different bacteria. Significant difference was found in MIC among different metal ions and for different bacteria. For example, MIC value of Cu ion for S. Typhimurium S9 was as high as 14000 μM while the value for P. phosphoreum was just 31.2 μM. Different researchers reported different MIC values due to the different testing methods.

Table 1.

Minimum inhibitory concentration (MIC) for different bacteria.

| Elements | MIC (μM) | Bacterium | Ref. |

|---|---|---|---|

| Ag+ | 37.4 | E. coli | [82] |

| 37.4 | S. choleraesuis | ||

| 74.7 | S. aureus | ||

| 40 | S. epidermis | [81] | |

| Co2+ | 240 * | S. epidermis | [81] |

| >508.5 | P. phosphoreum | [83] | |

| Cr3+ | 384 | P. phosphoreum | [83] |

| Cu2+ | 10000 | S. Enteritidis SE | [84] |

| 12000 |

S. Typhimurium S19; S. Typhimurium S20 |

||

| 14000 | S. Typhimurium S9 | ||

| 7000 | S. aureus | [82] | |

| 4000 | E. coli | ||

| 4000 | S. choleraesuis | ||

| 31.2 | P. phosphoreum | [83] | |

| 110 | S. epidermis | [81] | |

| Fe3+ | 0.89 | P. phosphoreum | [83] |

| Mn2+ | 26812.3 | E. coli; S. choleraesuis | [82] |

| 29143.9 | S. aureus | ||

| Ni2+ | >6779 | P. phosphoreum | [83] |

| Zn2+ | 11743 | S. aureus; E. coli; S. choleraesuis | [82] |

| >45.8 | P. phosphoreum | [83] | |

| >300 | S. epidermis | [81] | |

| <139.5 | S. aureus | [85] | |

| 155 | S. aureus | [86] |

Note: MIC data have been transferred into μM for comparison purpose.

Metal ion provides strong antibacterial ability, it on the other hand might lead to cytotoxicity or poor cytocompatibility. Heidenau et al. [81] evaluated cell toxicity of several metal ions by a growth inhibition test with L929 cell line. Their results showed that Ag+, Zn2+ and Hg2+ ions exhibited very strong cytotoxicity at low concentrations. Co2+ showed intermediate cytotoxicity whereas tissue cells tolerated relatively high concentrations of Cu2+ and Al3+. Table 2 summaries the LD50 value (a value which causes 50% cell death) of several metal ions to different cells. Although large difference in LD50 value was found, even for same cell line, Ag+, Cu2+, Co2+, Zn2+ and Ni2+ showed low LD50 value while Ti4+, Ta5+, Fe2+ and Fe3+ showed high LD50 value, indicating that Ag+, Cu2+, Co2+, Zn2+ and Ni2+ show potential higher cell toxicity than the others.

Table 2.

Cell toxicity of metal ions (LD50).

| Metal ion | Medium | Test method | LD50(μM) | Cell line | Ref. |

|---|---|---|---|---|---|

| Ag+ | DMEM with 10% FBS | MTT | 11.0 | human osteosarcoma cell line MG-63 | [87] |

| DMEM with 10% FBS | MTT | 9.0 | tumour-derived mouse macrophage cell line | ||

| L929: MEM with 10 vol% FBS | 10 vol% Giemsa staining | 4.25 | L929 | [88] | |

| MC3T3-E1: α-MEM with 10 vol% FBS | 2.77 | MC3T3-E1 | |||

| RPMI 1640 with 10 vol% FCS | WST-1 test assay | 3.5 | L929 | [81] | |

| Co2+ | Same as [88]above | 10 vol% Giemsa staining | 11.2 | MC3T3-E1 | [88] |

| 81.2 | L929 | ||||

| RPMI 1640 with 10 vol% FCS | WST-1 test assay | 34 | L929 | [81] | |

| Cr3+ | Same as [88]above | 10 vol% Giemsa staining | 12.7 | MC3T3-E1 | [88] |

| 743 | L929 | ||||

| Cu2+ | Same as [88]above | 10 vol% Giemsa staining | 15.9 | MC3T3-E1 | [88] |

| 41.5 | L929 | ||||

| RPMI 1640 with 10 vol% FCS | WST-1 test assay | 230 | L929 | [81] | |

| Fe3+ | Same as [88]above | 10 vol% Giemsa staining | 328 | MC3T3-E1 | [88] |

| 5420 | L929 | ||||

| Fe2+ | Same as [88]above | 10 vol% Giemsa staining | 583 | MC3T3-E1 | [88] |

| 6950 | L929 | ||||

| Ni2+ | Same as [88]above | 10 vol% Giemsa staining | 52.2 | MC3T3-E1 | [88] |

| 106 | L929 | ||||

| Ta5+ | Same as [88]above | 10 vol% Giemsa staining | 2060 | MC3T3-E1 | [88] |

| 1880 | L929 | ||||

| Ti4+ | Same as [88]above | 10 vol% Giemsa staining | 871 | MC3T3-E1 | [88] |

| 1090 | L929 | ||||

| Zn2+ | Same as [88]above | 10 vol% Giemsa staining | 90 | MC3T3-E1 | [88] |

| 92.8 | L929 | ||||

| RPMI 1640 with 10 vol% FCS | WST-1 test assay | 3.6 | L929 | [81] | |

| serum-free medium | MTT | 300 | Primary human aortic endothelial cells | [89] | |

| serum-free medium | MTT | 280 | Primary human aortic smooth muscle cells | [89] | |

| complete cell-culture medium | MTT | 215 | Primary human endometrial epithelial cells | [90] | |

| serum-free medium: 2 h + medium with serum: 24 h | MTT | 185 | Neuronal PC12 cells | [91] |

Note: a) MEM: minimum essential medium, b) DMEM: Dulbecco's modified Eagle's medium, c) FBS: fetal bovine serum, d) FCS: fetal calf serum, e) RPMI: Roswell Park Memorial Institute-a cell culture medium.

Metal ion provides strong antibacterial ability, it on the other hand might lead to cytotoxicity or poor compatibility. Heidenau et al. [81] evaluated cell toxicity of several metal ions by a growth inhibition test with L929 cell line. Their results showed that Ag+, Zn2+ and Hg2+ ions exhibited very strong cytotoxicity at low concentrations. Co2+ showed intermediate cytotoxicity whereas tissue cells tolerated relatively high concentrations of Cu2+ and Al3+. Table 2 summaries the LD50 value (a value which causes 50% cell death) of several metal ions to different cells. Although large difference in LD50 value was found, even for same cell line, Ag+, Cu2+, Co2+, Zn2+ and Ni2+ showed low LD50 value while Ti4+, Ta5+, Fe2+ and Fe3+ showed high LD50 value, indicating that Ag+, Cu2+, Co2+, Zn2+ and Ni2+ show potential higher cell toxicity than the others.

According to the general antibacterial mechanism, the strong antibacterial ability of metal is due to the accumulation of metal ion, thus high metal ion concentration will result in high antibacterial property. But on the other hand, the high metal ion concentration will also lead to cell toxicity. With above considerations, the alloying elements with low MIC and high LD50 will be the best choice for developing antibacterial metal alloys, such as Fe3+, Ag2+, Co2+, Cu2+ and Zn2+. Ag2+, Cu2+ and Zn2+ have been widely used as antibacterial agent but Fe3+ and Co2+ have not yet been reported to be an antibacterial agent.

4.1. Ag

Silver has a strong inhibitory and bactericidal effect on a range of bacteria, fungi and viral pathogens [92]. Silver ions and silver-based compounds are highly toxic to microorganisms [93] showing strong biocidal effects on as many as 16 species of bacteria [94]. The antibacterial activity of silver was first demonstrated in the 19th century. Now, the use of various forms of silver as a topical agent is commonplace [92,95]. Silver is certainly the metal most commonly used with the purpose to confer anti-infective properties to biomedical devices for its oligo dynamic antibacterial activity, i.e. exhibiting bactericidal/bacteriostatic activity at very low concentration [12] for dental and orthopedic implant applications [96,97]. Widely documented use of silver is prophylactic treatment of wounds, water disinfection, pleurodesis, cauterization etc. Silver was used as a biocide to sterilize recycled drinking water aboard of the NASA space shuttle and MIR space station [98]. However, the use of silver as bulk material in medical devices has progressively been ceasing. On the other hand, the utilization of Ag element in antibacterial surface modification has progressively been flourishing, such as nanoparticles loaded thin film [99,100], doped solid coatings [101], hydrogel materials [102], micro- and nanoparticles reinforced antibacterial glasses [103] and antibacterial polymer material [50]. Meanwhile, Ag element has also been used as an alloying element in preparation of antibacterial metal alloys [104,105].

It was reported that silver at low concentrations was not cytotoxic for osteoblast in vitro [106]. Controversially, debate still persists over the possible inactivation of silver mediated antibacterial activity in physiological fluids and over the low biocompatibility index of silver determined by the low threshold concentration for cytotoxic effects, especially inform of nanoparticles. Li [107] showed that nano-Ag had the potential to induce embryo cytotoxicity, although the toxicity was lower than Ag+ ion.

4.2. Co

Although some researchers reported that Co metal exhibited strong antibacterial ability, as mentioned above, Co2+ showed a high MIC value to several bacteria as listed in Table 1, and low LD50 value to cells as listed in Table 2, which indicates that Co and Co2+ are not a proper antibacterial alloying element. So far, Co or Co2+ has not been used as an alloying element or antibacterial agent in the development of antibacterial materials and coating.

4.3. Ce

Recently, Jing [108] reported for the first time that Ce-containing stainless steels with 0.11 wt% Ce and 3.25 wt% exhibited very strong antibacterial ability (>99% reduction). In comparison with antibacterial agent Cu and Ag elements, Ce element showed a high antibacterial efficiency, only 0.11 wt% Ce in steel provided with strong antibacterial properties. As for the antibacterial mechanism, it was suggested that Ce ion released from the Ce-containing alloy might have similar antibacterial effects as Cu ion and Ag ion. However, Ce release concentration was not detected in their report.

4.4. Cu

Long time ago, copper was used to clean up wounds on the chest and to purify water, to treat local skin ulcers in the legs and skin diseases, syphilis and tuberculosis. After copper was certified by the US Environmental Protection Agency (EPA) as having antibacterial properties in 2008 [109], its potential application for antibacterial activity has aroused more and more commercial interest. It has been reported that a copper surface can complete kill MRSA and E. coli within a few hours [110,111]. Many researchers have studied the antibacterial and bactericidal concentrations of Cu ions against different types of bacteria. Copper-sensitive bacteria, e.g., K. aerogenes were inhibited in their growth and survival in a range of 10−8-10−6 M Cu2+ ion concentrations [112]. When the Cu2+ concentration was 10−5 M, the sterilization rate to S. aureus was 92% while the sterilization rate to E. coli was 93% at 5 × 10−6 M Cu2+ [[113], [114], [115]]. Recently, Cu has been widely used to develop antibacterial materials, and some reviews have been published, including Cu-containing ceramic [116,117], Cu-containing polymer composites [118], and Cu-containing metal alloys [119,120].

In addition, copper is an essential metal ion to the proper functioning of organs and metabolic processes, which is incorporated into a variety of proteins and enzymes of organisms, such as cytochrome oxidase, superoxide dismutase, internal plasma copper blue protein, dopamine, β-hydroxylase, etc. [121]. Cu deficiency is harmful for human health, which may not only result in anemia, cardiac hypertrophy, coronary heart disease, arthritis, and osteoporosis, etc., but also influence the human secretion system and immune function, especially cardiovascular system [122]. The World Health Organization (WHO) reports that the minimal intake to prevent copper deficiency is 0.9 mg/day [123]. Cu ion can promote osteoblast proliferation, differentiation and migration [[124], [125], [126], [127], [128], [129]]. Cu ion also plays an important role in the cardiovascular system and has beneficial biomedical functions in promoting endothelial cell growth, inhibiting excessive proliferation of arterial smooth muscle, and reducing thrombosis [120,[130], [131], [132], [133]]. Zhang [134] recently proposed that in-stent restenosis might be prevented by the constant release of Cu ion due to inhibition of migration and proliferation of vascular smooth muscle cells by Cu ion. Due to the biofunction of Cu ion, it is proposed that the Cu-containing materials, including metal alloys might have both biofunction and antibacterial activity by special alloy design.

However, high concentrations of Cu ions will induce an inhibition of growth and have a toxic effect on humans [16]. Many researchers reported that the toxicity of Cu depended on the existing form of Cu element. Thit [135] argued that all the three existing forms of Cu including poly-CuO, CuO NPs or Cu2+increased cell death and altered cell cycle progression, but poly-CuO caused the most severe effects. Bondarenko [136] indicated dissolution of CuO particles was the key factor triggering the reactive oxygen species (ROS) and DNA damage responses in bacteria. It was also reported that Cu ion might be related to Alzheimer disease [137].

4.5. Fe

Fe is a necessary trace element for human being, which is involved in many Fe-containing enzymes and proteins [138,139]. Fe plays significant roles in the human body, including the transport, storage and activation of molecular oxygen, and the reduction of ribonucleotides and dinitrogen [138]. WHO permissible maximum tolerable daily Fe intake is < 56 mg [140].

Wang's results [83] on the toxicity of some metal ions against P. phosphoreum indicated that Fe3+ showed the highest inhibition, followed by Cu2+ > Zn2+ > Co3+ > Cr3+ > Ni2+. It started to inhibit the bioluminescence at the concentration of 0.01 mg/L (0.18 μM) and reached complete inhibition when the concentration was only 0.05 mg/L (0.89 μM). However, pure Fe and Fe alloy do not exhibit any antibacterial properties.

So far, Fe or Fe ion has not been used as an alloying element or antibacterial agent in the development of antibacterial materials and coating. However, previous studies have revealed that pure Fe and Fe-based alloys were “safe” degradable implantable materials because they did not seem to be associated with inflammation, neointimal proliferation or thrombotic events [[141], [142], [143], [144]]. Moreover, Fe and Fe-based alloys do not have the issue of gas release during degradation compared with Mg and Mg-based alloys [145].

4.6. Ga

Recently, it was reported that gallium-doped specimens showed the best ALP synthesis and antibacterial properties [146]. In the report, Ga-doped coating was produced on titanium substrate by an anodic spark deposition (ASD) method. Ga-doped specimen reduced the bacterial viability by 70–80% against multi drug resistant (MDR) pathogen A. baumannii (DSM 30007) as well as two A. baumanni clinical isolates (AB1 and AB2). The antibacterial ability of Ga-doped specimen was much stronger than Ag-doped specimen.

Although it was reported that the presence of anatase formed during ASD process might confer antibacterial activity to all the ASD coatings, this effect was enhanced significantly by the presence of Ga. It was thought that the antimicrobial activity of the Ga-doped surface was mainly related to competition with iron in a “Trojan horse” mechanism: in bacterial metabolism, the role of Fe3+ ions is crucial, and is mediated by intra-membrane transport via siderophores; gallium ions (Ga3+) can effectively compete with Fe3+ for binding to siderophores, thus interrupting crucial Fe-dependent metabolic pathways in the bacterium. Moreover, Ga3+ can act intracellularly affecting iron homeostasis leading to different pathways damage.

4.7. La

It was reported addition of only 0.42 wt% La into 316L SS content could obtain excellent antibacterial activity (>99% reduction) against E. coli and S. aureus [147]. Another research also indicated that La- and Ce-containing 316L-4.36Cu alloy showed antibacterial activity to the sessile sulfate reducing bacteria (SRB) at the first 7 days due to the addition of rare elements La and Ce but the antibacterial activity disappeared at 21st day [148].

4.8. Sn

Many researchers reported the dopant Sn played a vital role in enhancing the antimicrobial activities [[149], [150], [151]]. Verissimo's research [149] on S. aureus growth on Ti–35Nb–3Sn showed for the first time that adding Sn to β-type Ti alloys strongly decreased the adhesion of S. aureus, but also increased mechanical properties. As for the antibacterial mechanism, it was proposed that the addition of Sn might change the wettability which may have changed surface properties to repel bacteria. It was also reported that the bacteria attachment decreased with the presence of Sn in the Ti oxide layer due to the change in the physical and chemical properties, such as wettability, surface architectures and chemical composition (SnO2). However, no negative sample was used in their studies. Research on the influence of Sn doping on the antibacterial activity of ZnO films found positive relationship between Sn doping level and antibacterial activity [151].

4.9. Sr

In recent years, strontium (Sr) has been incorporated into dental and orthopedic biomaterial to reduce microbial contamination and the antimicrobial activity of Sr2+ ions can be used to enhance the use of medical devices by inhibiting bacterial growth and reproduction and impeding permeability of cytoplasmic membrane, cell wall synthesis, replication of bacterial chromosomes and cell metabolism [[152], [153], [154]]. In addition, Sr is one of trace minerals (0.00044% of body mass) predominantly present in the calcified animal tissue. Shorr and Carter [155] discovered the usefulness of low doses of Sr in the treatment of osteoporosis in 1952. Several in vitro and in vivo studies on Sr-substituted hydroxyapatite (HA), biological glass and bio-ceramics revealed that they promoted osteoblast proliferation and down-regulated osteoclastogenesis in both normal and osteopenic cells, with an increase in the alkaline phosphatase activity.

Guida's research [156] suggested that the bactericidal action of strontium was more significant than that of fluoride. It was also suggested that the fast degradation of Sr-containing ceramic increased the local pH, which might inhibit the bacteria [157]. The antibacterial properties of HA nanoparticles against E. coli, S. aureus and Lactobacillus were reported to be improved after the calcium was half or totally substituted by strontium and the antibacterial ability was strongly dependent on the Sr concentration [158]. However, Sr2+ in a concentration of 0.19 mol/L to 1.11 mol/L did not exhibit any antibacterial function to A. viscosus, A. naeslundii, A. odontolyticus, S. mutans, S. salivarius, S. sorbinus, L. caesi, L. acidophilus, P. gingivalis, P. intermedia and A. actinomycetemcomitans [159]. It was also suggested that Sr release concentrations above 0.16 mmol/L (14 ppm) did not further improve bactericidal action [160].

Sr has not been used as an alloying element for titanium, steel and cobalt alloy design as biomedical materials, but has been used in magnesium alloys [[161], [162], [163], [164], [165], [166], [167], [168], [169]].

4.10. Zn

Zinc is used as an antibacterial agent in dental and formulated into oral health products to control plaque such us mouth rinses and toothpaste [170,171]. Based on this knowledge, Zn ion has been widely used in surface modification of metal implant as antibacterial agent to provide good antibacterial ability [[172], [173], [174], [175]].

However, the antibacterial mechanism of Zn containing coating has not been systematically elaborated [174]. Numerous studies have been conducted to clarify the antibacterial mechanism of ZnO, including some reviews [176,177], while the dispute remains existing. Antibacterial mechanism of ZnO is publicly recognized as ROS generation [178,179] and Zn2+ ion release [180], but most researchers maintain that the antibacterial property of ZnO mainly attributes to ROS generation. Li [178] considered ROS generation was the main antimicrobial factor for the photoexcited ZnO, because ROS concentration produced by nano-ZnO and their bacterial mortality rate kept linear relationship. Hu [179] observed no obviously high concentration of zinc ions when researched Zn-incorporated TiO2 coatings on titanium, thus it was believed the generation of ROS played a leading role in this work. In addition, for antibacterial mechanism of ZnO nanomaterials, increase membrane dysfunction [181], and internalization between the ZnO particles and the bacteria caused by electrostatic forces [182] are taken into account as well.

Compared with Ag and Cu, although Zn possesses a relatively weaker antibacterial activity [173], Zn ion shows non-cytotoxicity in a ranges from 10−6 M to10−5 M, as illustrated in Table 3. In addition, Zn plays important roles in DNA synthesis, enzyme activity, nucleic acid metabolism, biomineralization and hormonal activity, and it has long been recognized that zinc can stimulate bone formation [173,[183], [184], [185], [186]].

Table 3.

Zinc ion cytotoxicity.

| Concentration of Zn (μM) | Medium | Cell | Exposition time (h) | Test | Result | Ref |

|---|---|---|---|---|---|---|

| 20–80 | serum-free medium | Rat retinal cells | 24 | LDH |

20-40 μM: little cell death; 50 μM: 30%–40% cell death; 60-80 μM: almost 100% death |

[187] |

| 1–100 | serum-free medium | Human proximal tubular cells | 24–96 | MTT |

1-10 μM: ≥ 80% viability at 24–96 h; 50 μM: ≥ 80% viability until 48 h while then 30%–40% cell death; 100 μM: significant cell reduction at 24–96 h |

[188] |

| 2–300 | DMEM/MEM +5%FBS |

U–2OS (human cell line derived from osteosarcoma) | 24 | WST-1 |

2-120 μM: > 70% viability, 180–300 μM: nearly 100% cell death |

[189] |

| 2–300 | DMEM/MEM +5% FBS |

L929 | 24 | WST-1 |

2-80 μM: > 70% viability, 120-300 μM: nearly 100% cell death |

[189] |

Note: a) MEM: minimum essential medium, b) DMEM: Dulbecco's modified Eagle's medium, c) FBS: fetal bovine serum.

5. Standards or methods

So far, there is only one standard to assess the antibacterial activity of metals and alloys, SN/T 2399-2010 China, but there are several methods and standards to measure the antibacterial activity of plastic materials, as listed in Table 4. The standard SN/T 2399-2011 is based on JIS Z 2801. In all test methods, glass wear such as Petri dish or culture plate is normally selected as a negative sample. Also, a well-known metals and alloys that do not show antibacterial ability such as pure titanium is selected as a control sample.

Table 4.

Some Standards for the measurement of the antibacterial activity of solid materials.

| Country/Organization | Standards No. | Title | Remarks |

|---|---|---|---|

| China | SN/T 2399-2010 | Evaluation method for antibacterial metallic materials | Based on JIS Z 2801―2000 |

| ISO | ISO 22196:2016 | Measurement of antibacterial activity on plastics and other non-porous surfaces | ISO22196:2007 is Based on JIS Z 2801―2000 |

| China | GB/T 31402-2015 | Plastics-Measurement of antibacterial activity on plastics surfaces | ISO 22196:2007, IDT |

| Japan | JIS Z 2801―2000 | Antimicrobial products―Test for antimicrobial activity and efficacy | |

| UK | BS ISO 22196:2016 | Measurement of antibacterial activity on plastics and other non-porous surfaces | ISO 22196:2016 |

| USA | ASTM E3031-15 | Standard Test Method for Determination of Antibacterial Activity on Ceramic Surfaces. | Ref. ISO-22196 |

| USA | ASTM G21―15 | Standard Practice for Determining Resistance of Synthetic Polymeric Materials to Fungi | |

| ISO | ISO20645: 2004 | Text fabrics-Determination of antibacterial activity-Agar diffusion plate test | |

| China | GB/T 20944.1–2007 | Textiles—Evaluation for antibacterial activity—Part 1: Agar diffusion plate method | ISO 20645:2004 |

5.1. Agar diffusion plate test

Specimens of the materials to be tested are placed on two-layer agar plates. The lower layer consists of a culture medium free from bacteria and the upper layer is inoculated with the selected bacteria. The specimens are tested on both sides. The level of antibacterial activity is assessed by examining the extent of bacterial growth in the contact zone between the agar and the specimen and, if present, the extent of the inhibition zone around the specimen. Thus, the width of the inhibition zone represents the antibacterial ability: the larger the inhibition zone is and the strong the antibacterial activity is.

According to the Standard ISO 20645: 2004 (BS EN ISO 20645: 2004 or GB/T 20944.1), the hot agar solution is first spread evenly with a Conrage stick on the sterilized Petri dishes and is allowed to congeal under sterile conditions. A suspension of bacterium, such as S. aureus or E. coli, is sprayed evenly over the total area of each Petri dish. A test sample, a control sample and a positive sample are separately placed and contact with the agar closely in the Petri dish. After this, the Petri dishes with samples are incubated immediately at (37 ± 1) °C for 18 h–24 h. The antibacterial activity is accessed by the width of an inhibition zone (H) around the sample calculated by the following formula

| (1) |

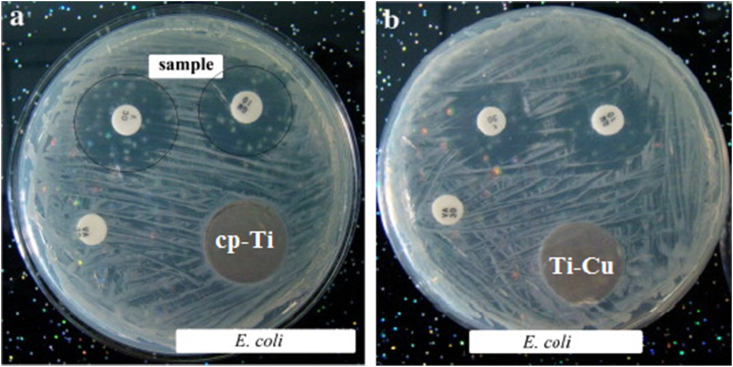

where, H is the inhibition zone in mm, D is the total diameter of sample and inhibition zone in mm and d is the diameter of the sample in mm, respectively. After measuring the inhibition zone, the specimens will be removed from the agar with a pair of tweezers and the bacterial growth in the nutrient medium under the specimen with a microscope at 20 times magnification. Inhibition zone up to 1 mm with no bacteria growth under specimen or no inhibition zone with no bacteria growth means good antibacterial effect of the specimen. As an example, Fig. 4 shows the inhibition zones around samples in the agar diffusion plate test. An inhibition zone was clearly observed around the white positive sample, indicating that the positive sample exhibited strong antibacterial ability against E. coli. On the other hand, there was no inhibition zone around cp-Ti and Ti–Cu alloy, indicating that both cp-Ti and Ti–Cu alloy did not kill the surrounding bacteria.

Fig. 4.

Inhibition zones around different samples against E. coli (the white sample is the positive sample). a) cp-Ti and b) Ti–Cu samples [18], copyright 2013, Elsevier B.V.

5.2. Plate-count method

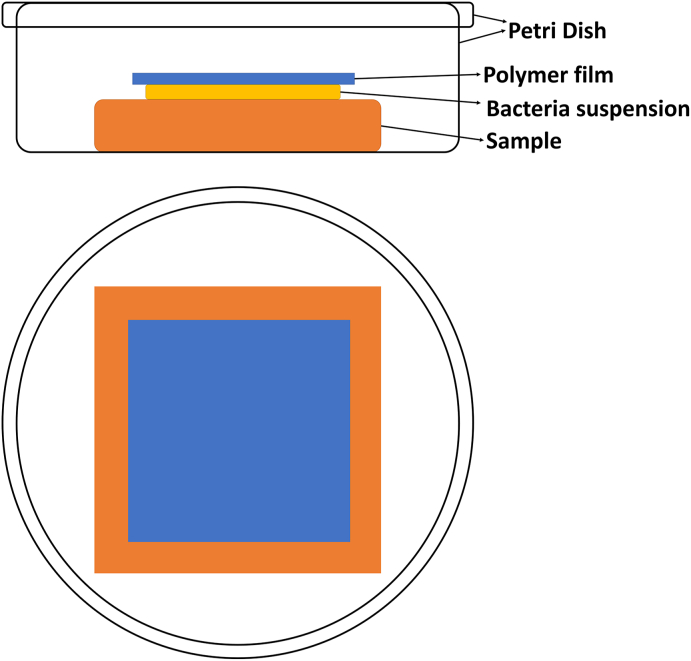

Although the plate-count method is intended to evaluate the antibacterial activity of antibacterial plastics (JIS Z 2801―2000, ISO 22196-2016, GB/T31402-2015) and other non-porous surface of products (ISO 22196-2016), this method has been widely adopted to assess the antibacterial activity of metals and alloys. The experiment process has been described in detail in JIS Z 2801―2000, ISO 22196 or GB/T31402-2015. Briefly, samples are placed in Petri dishes separately. Then, the bacterial suspension (0.4 mL in the standard, not less than 0.1 mL) is dripped onto the sample, including the test sample, the control sample and the negative sample. After this, the sample is covered by a sterile polyethylene film with a dimension to make sure that the suspension spreads to, but does not leak beyond the edges of the film, as shown in Fig. 5. Then the samples with bacterium are incubated at (35 ± 1) °C for 24 h under a humidity of ≥90%. After the incubation, 10 mL or more sterilized physiological saline solution is added to the Petri dish to wash the sample and the polymer film completely to make sure that no bacterium is left on the sample and the film. Then 0.1 mL the above washing solution is inoculated onto nutrient agar plates and incubated at (35 ± 1) °C for 24 h under a humidity of ≥90%. The active bacteria colonies are counted. Three samples are assessed for each type of samples. The antibacterial activity, R, is calculated by the following formula:

| (2) |

where, Ncontrol and Nsample are the average numbers of the bacterial colony on the control sample and the tested sample, respectively.

Fig. 5.

Schematic diagram of the plate-count method.

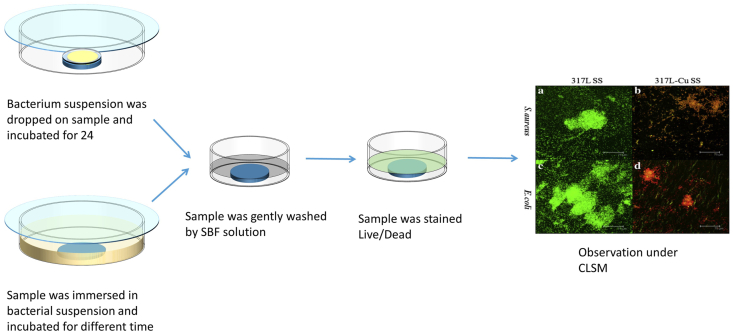

5.3. Live/dead stain

Live/dead stain is another method which has been widely used to observe the bacterium adhesion, biofilm and dead bacterium in order to assess the antibacterial properties. In this method, as shown in Fig. 6, bacterial suspension is dripped onto the tested samples or the sample is immersed in a bacterium suspension, and then incubated at 37 °C for 24 h. After incubation, the sample surface is washed gently for three times by using phosphate buffer saline (PBS) to remove the traces of culture medium. Then, two fluorescent dyes, LIVE/DEAD® BacLight™ Bacterial Viability Kits L7012 containing SYTO-9 dye and PI dye are used to stain the bacteria on the sample surface according to the instruction in dark at room temperature. After that, the dyed sample is observed under a confocal Laser scanning microscope (CLSM) at 514/488 nm in an argon laser. The bacteria with green color mean living bacteria and the ones with red color are dead bacteria. The inserted figures in Fig. 6 shows S. aureus and E. coli on 317L stainless steel and 317L-Cu stainless steel after incubation at 37 °C for 24 h [190]. Most of the bacteria on the surface of 317L stainless steel were stained in green whereas bacteria on the surface of 317L-Cu stainless steel were stained in both red and green, and the red color was significantly dominated.

Fig. 6.

Live/Dead stain method used to observe the surface bacterium. The inserted Fluorescent images show S. aureus and E. coli on surfaces of 317L stainless steel and 317L-Cu stainless steel after incubation at 37 °C for 24 h [190], copyright 2012, Elsevier B.V.

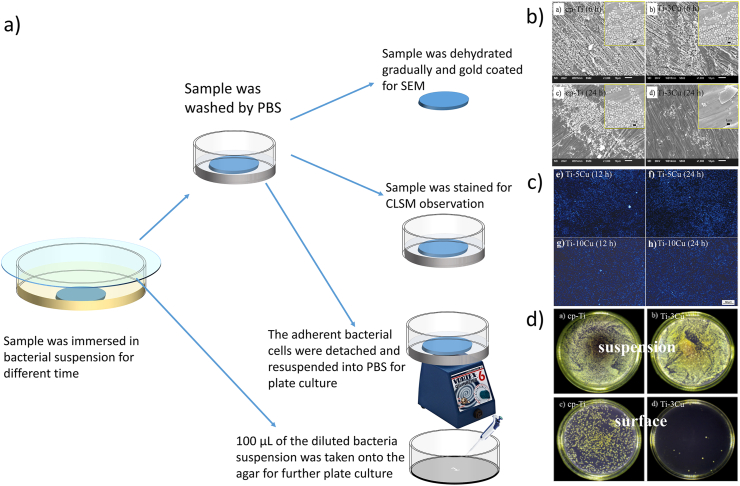

5.4. Immersion test

In some cases, the antibacterial activity against both the adhered bacteria and the planktonic bacteria properties need to be investigated, thus the immersion test method will be used. In the immersion test, as shown schematically in Fig. 7, the sample is immersed in a bacterium suspension, and incubated at 37 °C for 24 h (or for different time to assess the dynamic antibacterial properties), then the sample is taken out and washed gently by sterilized SBF solution to remove non-adherent bacterial cells. After this, the sample is gradually dehydrated and gold coated for SEM evaluation, as shown in Fig. 7b or the sample is stained with biological stain (400 μL Triton X-100 and 0.4 μL DAPI solution for example) for fluorescence microscope observation, as shown in Fig. 7c, or the sample is Live/dead stained as described above. By this way, the bacterium adhesion or biofilm formation can be clearly observed, which can directly reflect the anti-adhesion and anti-biofilm property of metal and alloy. Sometimes, the adherent bacteria cells on the sample are detached and resuspended into PBS by a two-step vortexing procedure at 4 °C for 1 min for each step to avoid unnecessary cell deaths. Serial dilutions (10−2 and 10−3) of the suspensions are plated on BHI agar plates and incubated overnight, followed by visual counting of colony forming units (CFUs) [191], as schematically shown in Fig. 7d. The antibacterial activity can be calculated by Eq. (2).

Fig. 7.

(a) Schematic diagram of the immersion method. (b) cell adhesion and biofilm under SEM [193], copyright 2018, Elsevier B.V.; (c) DAPI staining P. gingivalis on cp-Ti and Ti–10Cu alloy [194], copyright 2016, The Japanese Society for Dental Materials and Devices; (d) typical bacterium colonies from sample surface and the suspension [193], copyright 2018, Elsevier B.V.

Meanwhile, 100 μL of the bacteria suspension is taken onto the agar for further plate culture at 37 °C for 24 h and the bacteria colony is counted to assess the antibacterial properties of the sample against the planktonic bacteria by Eq. (2) [192], as shown in Fig. 7d.

5.5. In vivo test

In fact, antibacterial metal implants are in continuous contact with physiological fluids, including plasma in the human body and saliva in the oral cavity. Thus, in vivo microbial adhesion and plaque formation on biomaterial surfaces is influenced by factors such as multi-species oral pathogens, “host adhesions” (e.g. fibrinogen, fibronectin, collagen, and plasma albumin), host cells (cells of the innate and adaptive immune system) and the pellicle, a rapidly created conditioning film which covers a newly implanted device [2]. Another important limitation of in vitro studies is the protein concentration in artificial body fluids. This is because simply using a single host protein or a small selection of these cannot reflect the highly complex oral conditions in vivo [2].

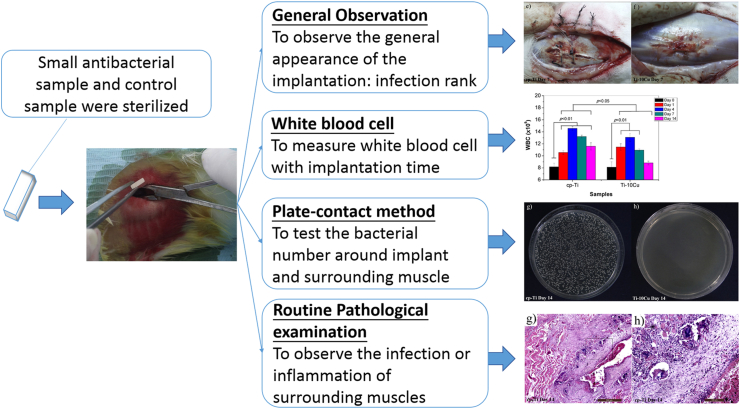

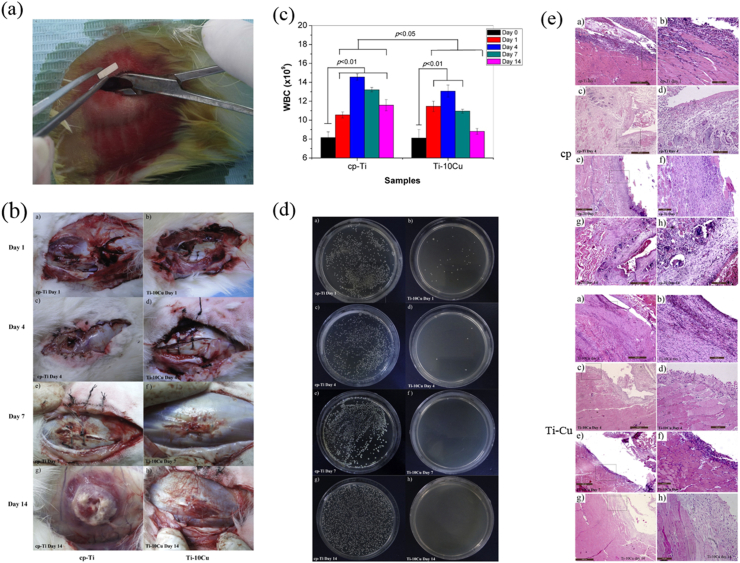

However, no standard on the in vivo test method has been set up so far. Recently, an in vivo test was used to determine the in vivo antibacterial activity of Ti–Cu alloy [195]. Briefly, sample with bacterium was implanted in the muscle of a rabbit. Postoperatively, the general observation, the white blood cell test, the plate-count method and the routine pathological examination were conducted to examine the inflection or inflammation situation surrounding the implantation site to reveal the in vivo antibacterial activity, as illustrated in Fig. 8.

Fig. 8.

Illustration of in vivo test of antibacterial titanium alloy. The inserted images show the general appearance, the blood cell test, the typical bacterium colonies and the pathological examination in vivo [195], copyright 2019, Elsevier B.V.

6. Antibacterial stainless steels

Stainless steels have been widely used as a biomaterial for fabricating cardiovascular stents/valves, orthopedic prosthesis, dentistry and other devices and implants used in biomedicine due to their good mechanical properties, corrosion resistance, biocompatibility and low price [196]. However, the lack of antibacterial properties is their great weakness in biomedical application. Nisshin Steel (Tokyo, Japan) developed the first copper-containing antibacterial stainless steel in the late 1990s [197,198]. Since the beginning of this century, lots of researches have been carried out and various types of copper-containing or silver-containing antibacterial stainless steel have been investigated so far including ferritic antibacterial stainless steel, austenitic antibacterial stainless steel, martensitic antibacterial stainless steel, as well as duplex antibacterial stainless steels [199,200]. Antibacterial alloying elements such as Cu and Ag are added into traditional stainless steel, which provides traditional stainless steel with antibacterial function and therefore is expected to provide a new approach to solve the problem of peri-implantitis for biomedical application [16].

6.1. Antibacterial properties

There are lots of factors that have influence on the antibacterial properties of stainless steel. As listed in Table 5, Cu-containing stainless steels exhibit excellent broad-spectrum antibacterial properties against lots of bacteria, such as S. aureus, B. coil, C. albicans, S. epidermis, S. lutea, E. coli, S. marcescens, B. pumilus, E. faecalis, S. fexneri, P. aeruginosa, P. sp as well as P. gingivalis, etc. However, antibacterial stainless steel shows different resistant ability to different bacteria. Nan [201,202] reported that antibacterial stainless steel had relatively stronger effect to Gram-negative bacteria than to Gram-positive bacteria, possibly because Gram-negative bacteria possessed thinner cell wall and were more susceptible to be damaged. The antibacterial stainless steel currently developed is mainly targeted at E. coli and S. aureus which are most common causes of implant-associated infections.

Table 5.

Antibacterial stainless steels.

| Alloy system | Alloy | Bacteria (antibacterial rate[Ref.]) |

|---|---|---|

| Ferritic stainless steel | 430-1.8Cu |

S. aureus, E. coli, B. coil, C. albicans, S. epidermis, S. lutea, S. fexneri and P. aeruginosa (all > 99% [199,201]); B. subilis (80% [199]); S. marcescens, B. pumilus, E. faecalis (98.2%, 97.7%, 91.0%, respectively [201]) |

| Austenitic stainless steel | 304-xCu (x = 1.5–5.5, 9,18 wt%) |

S. aureus (23.4%–99.9% [199,203,204]); E. coli (20%–99.9% [[204], [205], [206], [207]]); B. coil (10.6%–99% [200]); C. albicans, S. epidermis, S. lutea, S. fexneriand P. aeruginosa (all ≥ 99% [199,201]); P. gingivalis (100% after 12 h [16]); B. subilis(80% [199]); S. marcescens, B. pumilus, E. faecalis (99.5%, 92.4%, 93.6%, respectively [201]); planktonic bacteria in Tap Water (33.3%, 96%, 76.7% at 24 h, 48 h, 72 h [208]) |

| 304-xAg (x = 0.039–0.3 wt%) | E. coli (70.8–99.9% [209]); S. aureus (99.7%–99.9% [209]); P. sp [210] | |

| 304-xCe (x = 0.01–3.25 wt%) | E. coli (12.3–99.0% [108]); S. aureus (74.0%–99.4% [108]) | |

| 316-xCu (x = 2.46–4.5 wt%) |

S. aureus (95.2%–99.9% [211,212]); E. coli (25%–99% [[211], [212], [213]]); S. epidermidis (94.1% [212]) |

|

| 316L-xLa (x = 0.05–0.42 wt%) | S. aureus (15%–99.6% [147]); E. coli (9%–99.9% [147]) | |

| 317-4.5Cu |

E. coli (99.9% in vitro and in vivo [214], 92.7% in the artificial urine for 24 h and 90.3% in the human urine for 6 h [215]); S. aureus (99.0% [32,214,216], in vivo [214]) |

|

| Martensitic stainless steel | 410-xCu (x = 1.52–4.74 wt%) | E. coli (96–99.99% [217]) |

| 420-xCu (x = 0.4–5 wt%) |

S. aureus (35.4%–99.9% [197,198,[218], [219], [220]]); E. coli (43.6%–99.9% [218]) |

|

| Cr17Ni4–Cu (x = 3.4–5.06 wt%) | S. aureus (82%–99% [221]) | |

| Duplex stainless steels | 200-xCu (x = 1.45–3.57 wt%) |

S. aureus (42.8%–93.6% [202,222]); E. coli (56.1%–97.1% [202,222]) |

| 2205-0.2Ag | E. coli (100% [223]), S. aureus (99.6% [223]) | |

| 2205–3.02Cu | P. aeruginosa (33.1% [224], 99.5% [225]) | |

| Cr26Ni5Mo2-3.17Cu-0.07Ag | E. coli (>99% at 3 h and 6 h [226]) |

Note: 24 h incubation as default.

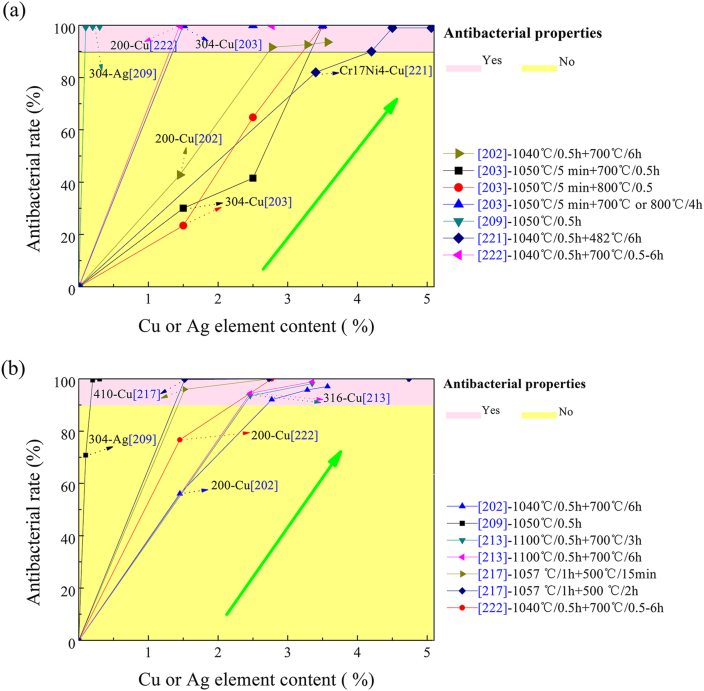

The content of antibacterial alloying element in stainless steels plays a very important role in the antibacterial properties. Normally, high content leads to strong antibacterial ability. However, high Cu content for example on the other hand might has side effect on the mechanical properties, the processing parameter and the corrosion resistance. Cu content in stainless steels is normally in a range of 1.52–5.5 wt% to obtain strong antibacterial ability. Fig. 9 summarizes the effect of Cu or Ag content on the antibacterial rate of some antibacterial stainless steels. 304 stainless steel containing 1.5–2.5 wt% Cu did not exhibit good antibacterial ability (<65%) in aging state, but increasing the Cu content to 3.5 wt% improved the antibacterial rate greatly to as high as > 99.99% [203]. Nan [222] reported that 200 stainless steel with 1.45 wt% Cu showed only 78.7% reduction against E. coli and >99.99% against S. aureus, but 200 stainless steel with 2.77 wt% Cu showed strong antibacterial activity (>99.99%) against both E. coli and S. aureus, indicating Cu content in 200 stainless steel has to be higher than a critical value, such as 2.77% in their study, to get good antibacterial ability. Wang [221] also revealed that the Cu content in a Cr17Ni4-(3.4–5.06)Cu had to be 4.2 wt% in order to get good antibacterial activity (>90%) or 4.5% Cu to obtain strong antibacterial ability (>99.9%).

Fig. 9.

Relationship between Cu content and antibacterial rate of stainless steel. a) against S. aureus (data from Refs. [202,203,209,221,222]) b) against E. coli (data from Refs. [202,209,213,217,222]).

Ag element has much stronger antibacterial ability than Cu, thus the Ag content in stainless steel is significantly lower than Cu content, about 0.039–0.3 wt% Ag. 2205-0.2Ag double-phase stainless steel exhibited an excellent bacteria-inhibiting effect on E. coli and S. aureus with an antibacterial rate of 100% and 99.5%, respectively [223]. Liao [209] found 304 austenitic stainless steel with 0.2 wt% Ag had an excellent antibacterial rate above 99%. With the consideration of reducing corrosion resistance due to the Cu-rich precipitate, small amount of Ag was also added to a Cu-containing dual-phases stainless steel to prepare an antibacterial dual-phase stainless steel. The alloy exhibited strong antibacterial ability (>99.4% reduction) against E. coli at 3 h incubation [226].

It was also reported the more the Ce content in the stainless steel was, the stronger the antibacterial ability of the steels appeared and 304 stainless steel with merely 0.11% Ce (304–0.11Ce) has strong antibacterial activity (98.9% reduction against E. coli and 99.1% against S. aureus) [108]. The addition of La also contributed to the antibacterial activity in a dose dependent method [147]. When the La content in 316L was about 0.05%, no antibacterial activity was found. With the increasing of La content increased to 0.11 wt%, 0.19 wt% and 0.42 wt%, the antibacterial rate increased to 54–62%, 78–89% and >99.6% against E. coli and S. aureus, respectively. However, all these alloys exhibited antibacterial function only to the sessile bacteria rather than surrounding planktonic bacteria.

The processing process of antibacterial stainless steel also greatly influences the finial antibacterial properties. 304 stainless steel prepared by strip casting and cold rolling only caused 65% of E. coli bacteria death upon direct contact for 24 h even if the copper content was as high as 18 wt%, much less than the recommended value of 90% [205]. As-received Cu-containing stainless steels did not have antibacterial ability and solid solution treatment could not provide with strong antibacterial ability [213]. Only the sample underwent solid solution and subsequent ageing treatment to possess precipitated phase, showed a distinct antibacterial function [200,218]. It has been widely accepted that the antibacterial function of Cu-containing stainless steels was attributed mainly to the ε-Cu precipitate during heat treatment. Solid solution dissolves Cu element in matrix completely, thus the bacteria will not contact with Cu-rich compound, which will reduce the antibacterial activity significantly. After ageing treatment, nano-scale Cu-rich precipitates from the matrix and will be contact with bacteria during incubation, and kill the bacteria by some ways [220].

Further research displayed that aging temperature and duration had influence on the antibacterial properties. The aging temperature should be high and the aging duration should be long enough for the complete precipitation of nano-scale Cu-rich phase from the matrix and thus resulting in a high antibacterial activity. In Wang's study [219], after being aged at 500 °C for 4 h, 420-3.5Cu alloy only had an antibacterial rate of 69.2% against S. aureus, while the ageing treatment at 500–800 °C for 6 h improved the antibacterial rate significantly to as high as > 94%. Similar results were also reported elsewhere, when the aging duration was extended to 240 min at 700 or 800 °C, even the addition of as low as 1.5 wt% Cu generated enough Cu-containing precipitates by long-time diffusion, to make the antibacterial rate reach at > 99.99% against S. aureus [203].

It was thought that solid solution treatment could provide strong antibacterial ability for Ag-containing stainless steels [209,223]. Ag and Fe have a low mutual solubility in both the solid and the liquid states, and the silver solidified and reacted with impurities forming a silver-rich compound during solidification to obtain strong antibacterial ability [223]. Compared to the conventional Cu- or Ag- bearing stainless steels, the Ce-bearing stainless steels exhibited good antibacterial ability after solid solution treatment, which was attributed to the precipitation of Ce-rich zones in the solid solution treated sample due to the low solubility of Ce [108].

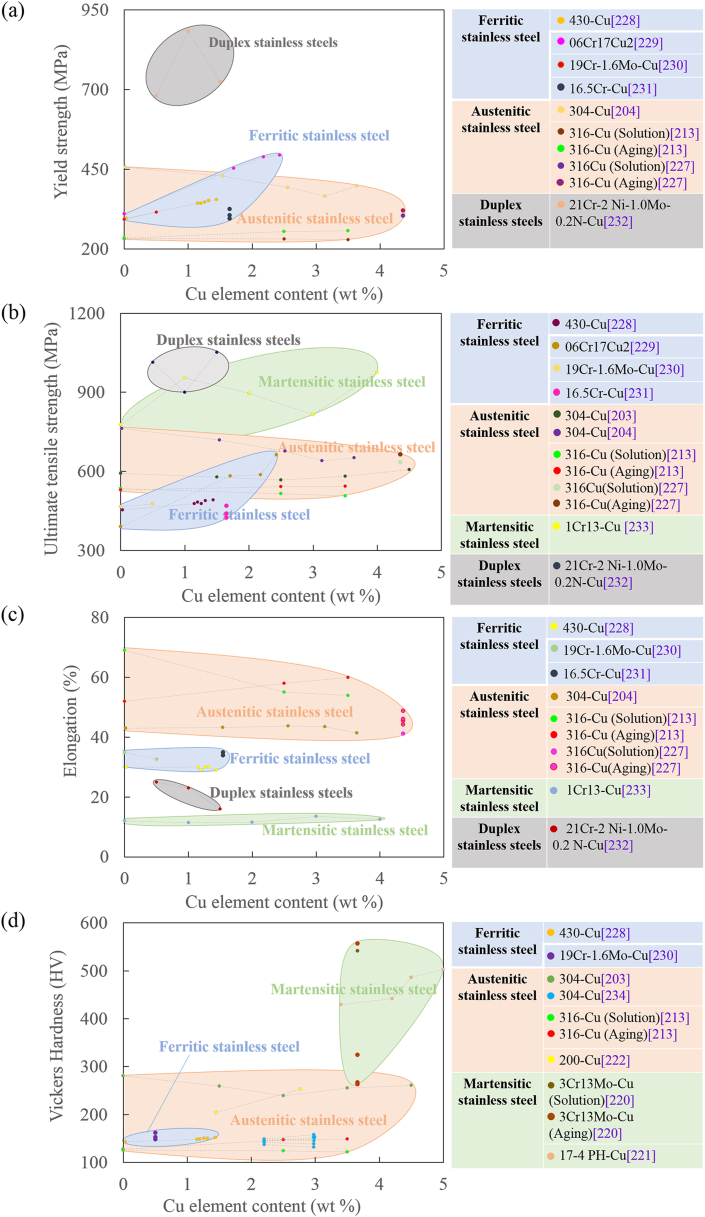

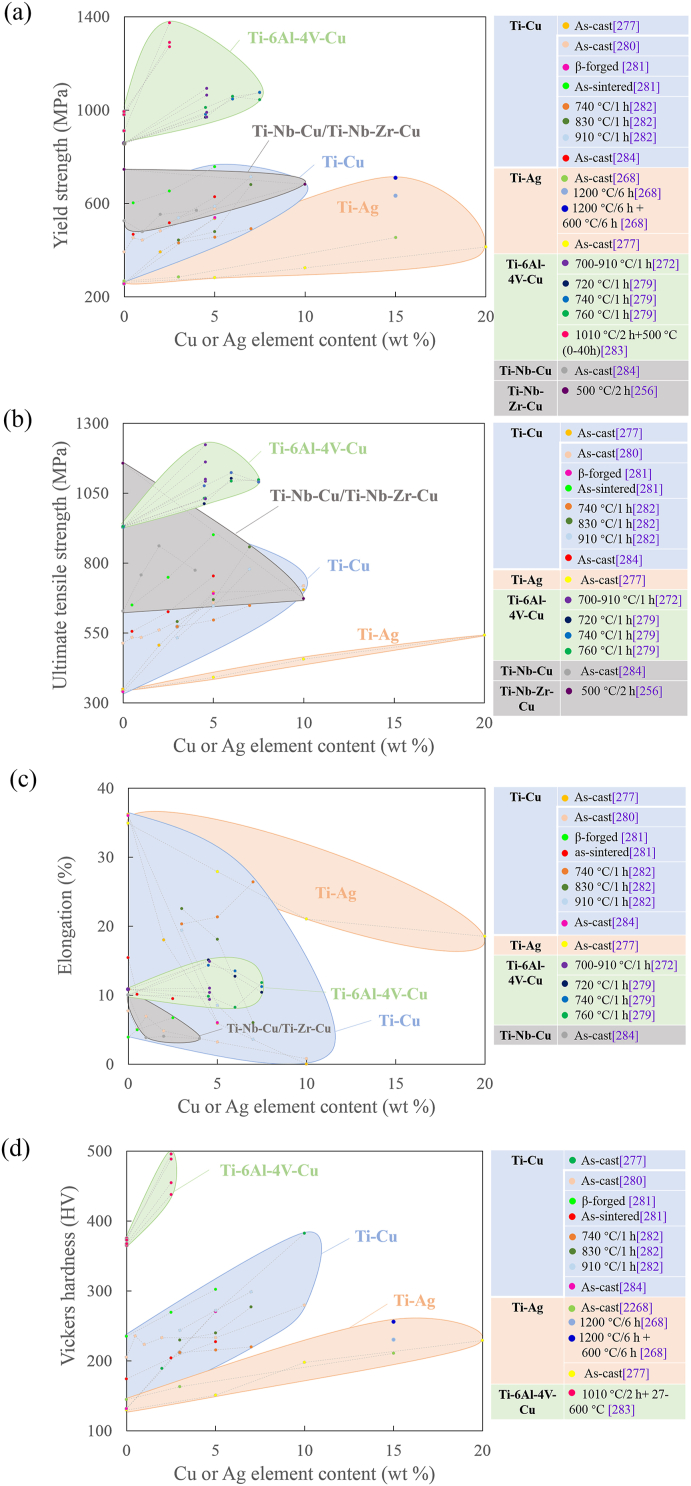

6.2. Mechanical properties

Cu and Ag elements have very low solid solubility in Fe matrix at room temperature. Cu and Ag normally do not form intermetallic phase with Fe matrix and exist in Fe matrix as solid solution state or Cu- or Ag-rich phase. It was reported addition of sufficient Cu could increase mechanical properties (including strength and hardness) such as adding over 2.5 wt% Cu into 304 [203]. Xi [213] reported the strengthening effect of Cu was limited when the Cu content reached at 2.5% for 316L-Cu no matter solution or aging treated, indicating Cu addition with 2.5 wt% was enough to precipitate sufficient Cu-rich phase for precipitation hardening. It was reported that low Cu addition (1.45 wt %) did not bring influence on hardness during 700 °C aging treatment, but high Cu content (2.77 wt%) significantly increased the hardness due to the precipitation of Cu rich phase [222]. In another research, the Vickers hardness of 17-4 PH-Cu stainless steel was positively related to the Cu content (3.4–5.06 wt%) [221]. Fig. 10 summaries the relationship between mechanical properties of antibacterial stainless steels and the Cu or Ag content.

Fig. 10.

Relationship between Cu content and mechanical properties of stainless steel (data from Refs. [203,204,213,[220], [221], [222],[227], [228], [229], [230], [231], [232], [233], [234]]). a) yield strength b) tensile strength, c) elongation d) hardness.

It was also suggested that the addition of Cu had tiny influence on the mechanical properties of solution treated stainless steel, which were mainly attributed to the synergistic effect of the softening effect by increase of stacking fault energy (SFE) and strengthening effect by the solid solution strengthening [213]. Nano-scale Cu-rich precipitation caused by the saturated Cu in the steel in the aging treatment played a positive role in mechanical properties [213,222]. The yield strength of 316L-Cu was almost similar to that of 316L after solution treatment, whereas the aging treatment obviously increased the yield strength of 316L-Cu due to the formation of tiny Cu-rich precipitates [213,231].

Extension of the aging time after solution treatment can enhance the mechanical properties of antibacterial Cu-bearing stainless steels without impairing antibacterial properties, while hardly changes mechanical properties under exceeding critical ageing time [219,220]. As the aging time extended, the hardness of 200–2.77Cu increased rapidly and approached a peak value after 3 h, and then hardly changed [222]. In Xi's study [231], the mechanical property of 316L-4.36Cu remained steady with the aging time increasing from 20 min, further even up to 15 h, implying the modest precipitation hardening effect of Cu-rich precipitates.

It was reported the aging temperature could also affect the mechanical properties of antibacterial Cu-bearing stainless steel. As the aging temperature increased within 500–800 °C, the softening effect and the dislocation density decreased rapidly, resulting in a rapid decreased in the hardness of the 420-Cu steel [219]. Similarly, when the aging temperature increased from 500 °C to 800 °C, the strengthening and hardness of 3Cr13Mo–Cu gradually decreased, which was attributed to the Cu segregation zone in steel evolved into precipitated particles, and the pinning effect of Cu-rich phase on dislocation is weakened [220].

Wang [211] fabricated a novel type of low stiffness porous 316L-4.5Cu by selective laser with similar stiffness (3–20 GPa) with bone to prevent stress shielding. Such low stiffness porous structures, especially coupled with the addition of antimicrobial Cu, may provide a new direction for medical stainless steels.

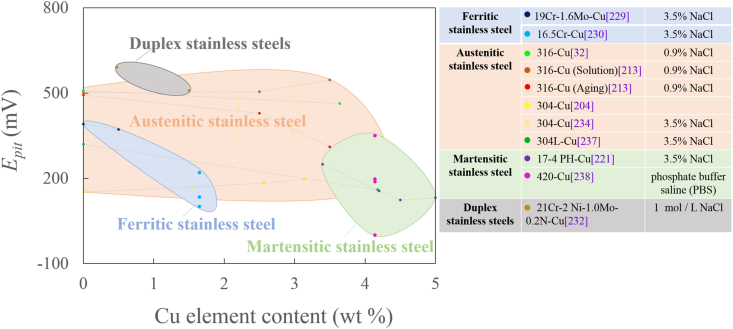

6.3. Corrosion properties

Long-lasting and broad-spectrum antibacterial activity of antibacterial stainless steel is inseparable from corrosion resistance. It is widely accepted the metal ion release, including Cu and Ag ion, controls mainly the antibacterial activity [206,235]. Thus, it is reasonable to believe that high metal ion release will lead to high antibacterial ability. The high metal ion release concentration on the other hand might cause cell toxicity. Therefore, one main challenge in the designing and manufacturing biomedical antibacterial stainless steels is how to optimize the chemical composition, especially the Cu content or Ag content, to balance the corrosion resistance, antibacterial property and cell compatibility. The research on the resistance of Cu-containing ASS to localized corrosion in humans (simulated with 0.9% NaCl solution or PBS buffer) is multiple, but has not been clarified sufficiently, and there are some controversial conclusions in different literatures [236]. Fig. 11 summaries the pitting corrosion potential (Epit) of antibacterial stainless steels.

Fig. 11.

Relationship between the Cu content and the pitting corrosion potential (data from Refs. [32,204,213,221,229,230,232,234,237,238]).

The corrosion properties of Cu-containing antibacterial stainless steels are closely related to the heat treatment process. It was reported that the Cu addition enhanced the corrosion resistance in the solution state under the mild corrosion environment (simulated with 0.9% NaCl solution or PBS buffer, 37 °C), whereas the corrosion resistance was detrimental after aging treatment [213]. After solution treatment, dissolved Cu ions in the surface would form a protective CuCl2 film in the chloride media, and was beneficial to improvement in the corrosion resistance of 316L-Cu [213]. However, in order to obtain high antibacterial ability, the antibacterial stainless steel has to be aged to precipitate Cu-rich phase from the matrix. Many researchers insisted the Cu-rich phase precipitated from a saturated amount of Cu in the steel matrix after the aging treatment formed galvanic corrosion with steel matrix and acted as a cathodic center, thereby accelerating the dissolution of the matrix [32,206,218]. The overall reaction was [32,221,239].

| (3) |

Cu-rich precipitates would destroy the uniform continuity and compactness of the passive film and act as the “weak points” on the steel surface which are susceptible to the local attack. As a result, the discontinuity of passive film caused by Cu-rich precipitates reduced the resistance to pitting corrosion and the ability of self-passivation and self-repairing [218,240]. Sun [32] reported that the addition of copper after aging treatment slightly decreased the pitting potential (Epit) of 317L, indicating the copper addition influenced the structure of the passivation film.

The aging time also has a certain effect on the corrosion resistance of the antibacterial stainless steel. Ren [241] reported that the radius of the capacitance arc in the Nyquist diagram of 304-3.9Cu was reduced gradually with the increase of the aging time, which indicates that formation of the passive film on surface of the steel was affected by the Cu precipitate in the steel, and thus the corrosion resistance of the steel was reduced to some extent. In another research, 304L-Cu possessed a higher intergranular corrosion tendency and a higher pitting corrosion rate with extended aging time [239].

The Cu content also has a great influence on corrosion performance of antibacterial stainless steels. It was reported that the increase of copper content in Fe–18Cr–Cu could increase the tendency toward chromium segregation at grain boundaries and thus the tendency toward intergranular corrosion of cast alloys [240]. In Xi's study [213], the corrosion resistance increased as the Cu content (0, 2.5%, 3.5%) increased for the solution-treated 316L, while opposed for the aged steel. In those higher Cu-content alloys that contain Cu-rich precipitates, the anticorrosion performance of the steel was greatly deteriorated, with the corrosion mechanism changing from pitting corrosion to selective corrosion [205]. Wang [221] reported the potentiodynamic polarization curve of Cr17Ni4–Cu in 3.5% NaCl solution shifted to the more negative direction, and Epit and ipit were more negative with increasing Cu content, which was believed to be related to Cu-rich phase formed after ageing treatment.

However, few researches indicated that the Cu had no adverse effects on the corrosion resistance of antibacterial stainless steels under the mild corrosion environment of 0.9% NaCl solution. The effect of trace Cu is similar to that of nickel, which will improve the corrosion resistance of weathering steel by forming a dense protective rust layer on the surface [119]. Nan [222] reported the passivity domains were very close between 200 and 1.45Cu with low copper content and 200–2.77Cu with high copper content after aging treatment at 700 °C, indicating that addition of Cu in the 200 stainless steel did not have strong influence on the corrosion resistance.

Antibacterial stainless steels showed excellent corrosion behaviors in bacterial solution. The addition of Cu or Ag improves the pitting corrosion resistance of stainless steel [210,242,243]. It was suggested that Cu-rich precipitates will be changed to Cu2+ partially due to the interaction between the materials and bacterium in the bacterial solution, which should reduce the conductivity of the surface of the steel, and result in a lower icorr of antibacterial stainless steels [207,243]. The presence of Cu in the 304L-Cu SS inhibited the pitting corrosion due to E. coli [242]. The pitting corrosion resistance of 2205-Cu was significantly better than that of 2205 in the presence of P. aeruginosa [243]. It was reported that Ag containing 304 (0.039Ag) restricted bacterial (P. sp) adhesion compared to the normal stainless steel, which reduced the pitting corrosion [210]. Yuan [244] reported the microbiological (S. aureus) corrosion resistance of 316L containing an appropriate amount silver was improved, but an excessive silver was prone to form segregation and degrade the corrosion resistance. In addition, La and Ce were believed to improve the anticorrosion performance of 316L in a medium containing sulfate reducing bacteria (SRB) [148].

6.4. Biocompatibility

The metal ion release from antibacterial stainless steels plays a very important role in the antibacterial behavior. So far, the research results have demonstrated that Ag- or Cu-containing stainless steels have good biocompatibility in vitro similarly with traditional biomedical stainless steels, which offers a prerequisite for the in vivo (animal test) and provides an important judgement for the development and application of antibacterial stainless steels.

The results of cell compatibility of antibacterial stainless steel in vitro are summarized in Table 6, results clearly showed the cells viability of Ag- or Cu-containing antibacterial stainless steels was improved or not significantly different compared to stainless steels, indicating that Ag- or Cu-containing antibacterial stainless steels had no cytotoxicity to MG-63 cells [16,214], KB cells [16], rMSCs [211], UECs [215,245], SaOS-2 cells [246] and MC3T3-E1 cells [216]. Moreover, the apoptosis rates to MG-63 [16], KB cells [16], UECs [245], SaOS-2 [246] of Ag- or Cu-containing antibacterial stainless steel decreased or had no significant difference compared with the control stainless steel. It can be found 316L-Cu SS behaved the fast in cells migration, which was beneficial to the endothelialization [215]. In addition, Ren [246] reported 317L-Cu alloy could promote the osteogenic differentiation by stimulating the alkaline phosphatase enzyme activity and the osteogenic gene expressions (including Col1a1, OPN, and Runx2).

Table 6.

The cell biocompatibility of antibacterial stainless steel.

| Test | Alloy system | Year | Cell line | Method | Result (antibacterial stainless steel compared with stainless steel) | [Ref.] |

|---|---|---|---|---|---|---|

| Cell viability | 317L-4.5Cu | 2011 | MG-63 | MTT | significant cellular growth | [16,214] |

| 2015 | SaOS-2 | MTT | no significant difference | [246] | ||

| 2016 | MC3T3-E1 | real-time cell analysis (RTCA) | no significant difference | [216] | ||

| 304-3.9Cu | 2013 | MG-63; KB | CCK-8 | no significant difference | [16] | |

| 316-4.5Cu | 2016 | rMSC | MTT | no significant difference | [211] | |

| 2016 | UEC | MTT | no significant difference | [215,245] | ||

| 2018 | UEC | MTS | significant cellular growth | [215,245] | ||

| Cell apoptosis | 304-3.9Cu | 2013 | MG-63; KB | Annexin V-FITC/PI staining | no significant difference | [16] |

| 317L-4.5Cu | 2015 | SaOS-2 | Annexin V-FITC/PI staining | significantly lower | [246] | |

| 316-4.5Cu | 2018 | UEC | Annexin V-FITC/PI staining | significantly lower | [215,245] | |

| Cell differentiation | 317L-4.5Cu | 2015 | SaOS-2 | ALP | mildly higher | [246] |

| cells migration | 316-4.5Cu | 2016 | UEC | wound healing assay | more cells migrated toward the wound | [215,245] |

Compared with the conventional 316L, Cu-containing 316L was proved to inhibit the inflammation reaction caused by endothelial dysfunction through blockading the inflammatory factors (TNF-α, IL-1β, 6, 8) to reduce the in-stent restenosis after the stent implantation, which would reduce the recruitment and infiltration of leukocytes, rather than have direct effect on leukocytes [247]. In addition, anti-fibrotic function of 316L-4.5Cu could reduce recurrence of ureteral stricture after stent implantation [248].

The continuous release of Cu2+ ions from 316L-Cu stainless steel will contribute to the Cu/Zn superoxide dismutase viability, which steadily reduces toxicity and encrustation [245]. Some researchers [215,249] reported 316L-4.5Cu had satisfied dual functions with anti-encrustation and anti-infection.

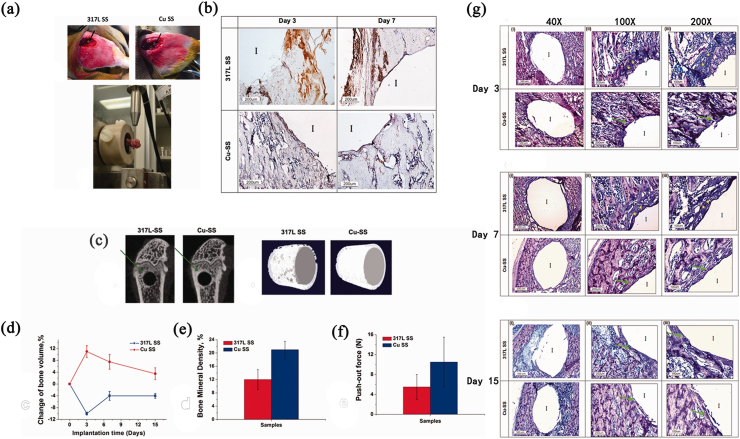

6.5. In vivo test

Antibacterial stainless steel has not been applied clinically, but 317L-4.5Cu and 316L-3.77Cu have been tested in vivo. The in vivo test results have demonstrated the good biocompatibility of antibacterial stainless steel, as listed in Table 7.

Table 7.

In vivo results of antibacterial stainless steel.

| Year | Antibacterial stainless steel | Animal model | In vivo results | [Ref.] |

|---|---|---|---|---|

| 2011 | 317L-4.5Cu | Japanese white rabbits | Strong antimicrobial activity, anti-inflammatory ability and strong promoting osteogenesis in vivo:

|

[214] |

| 2014 | 317L-4.5Cu | Sprague-Dawley rats | Strong anti-inflammatory ability, superior bone-implant integration and promoting osteogenesis in vivo:

|

[246] |

| 2016 | 317L-4.5Cu | zebrafish embryos | No in vivo cytotoxicity:

|

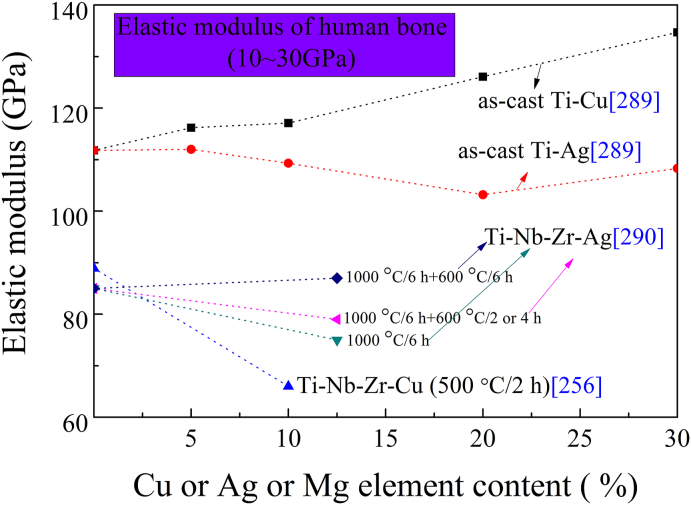

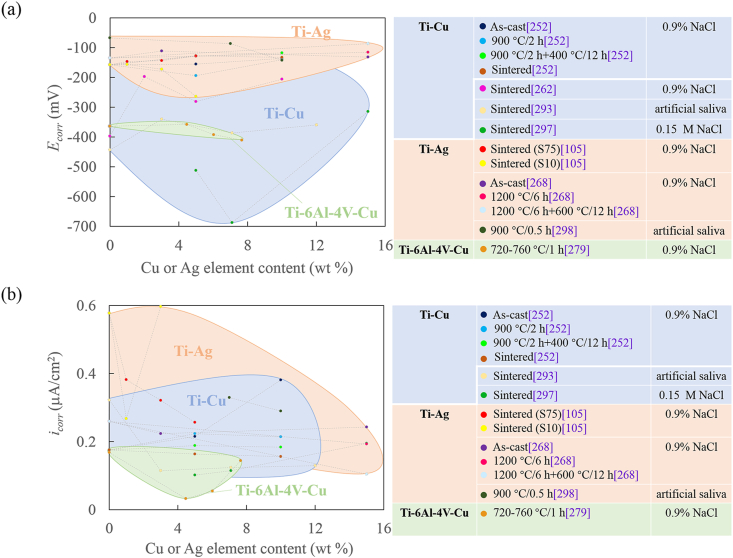

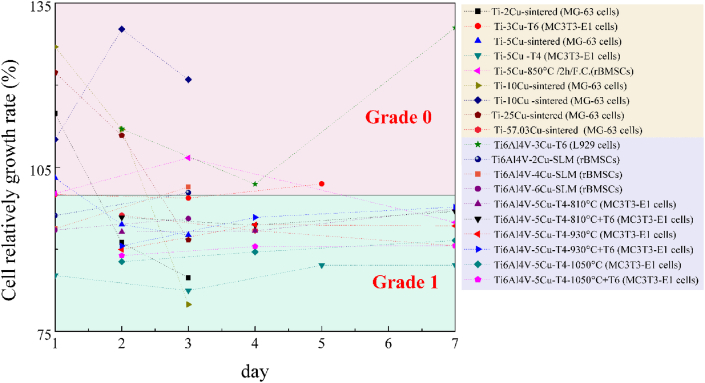

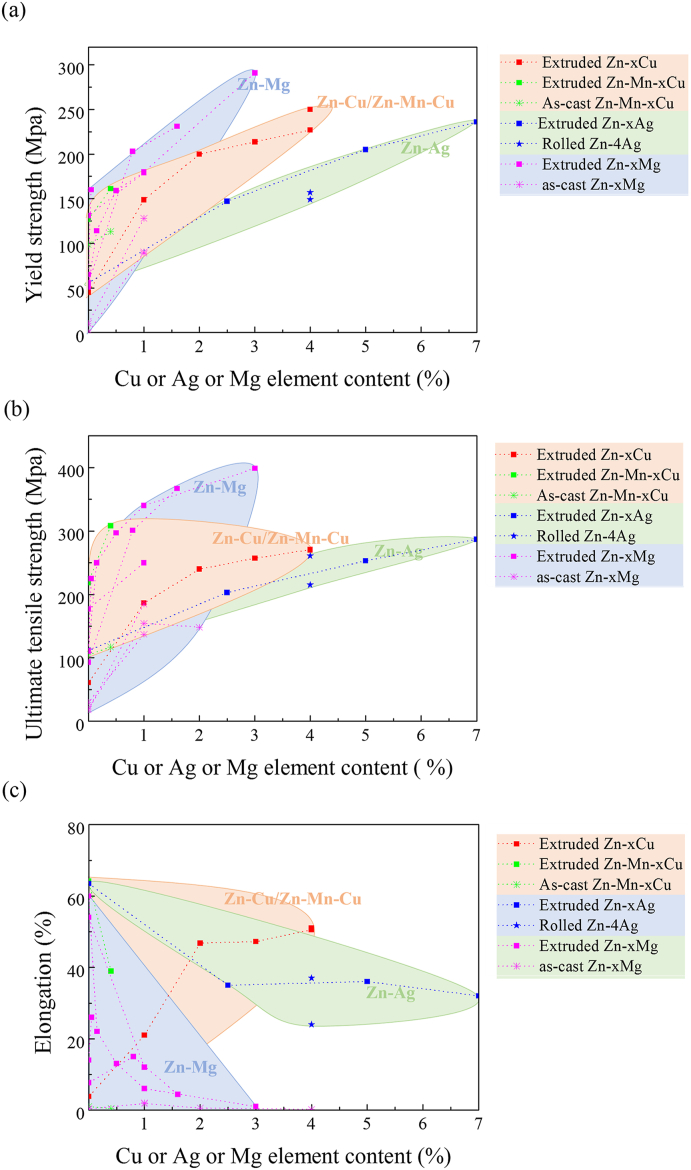

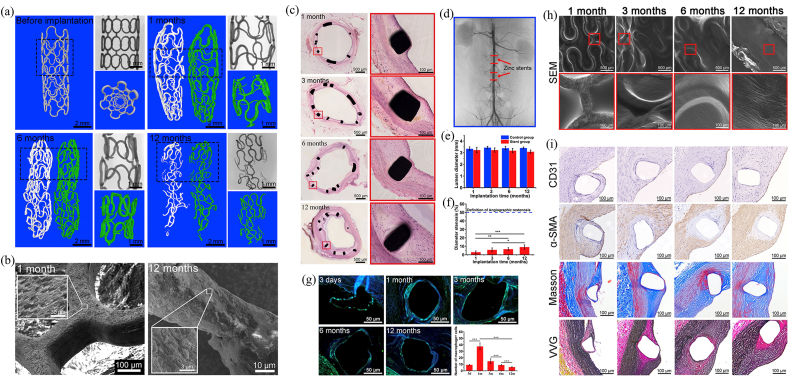

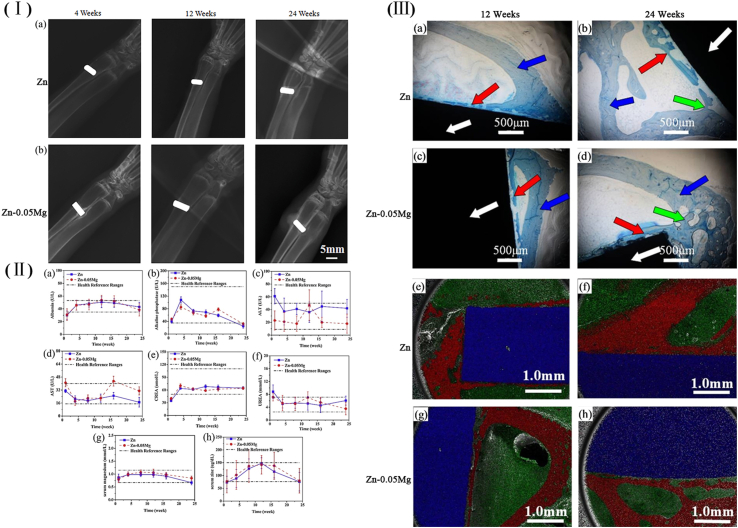

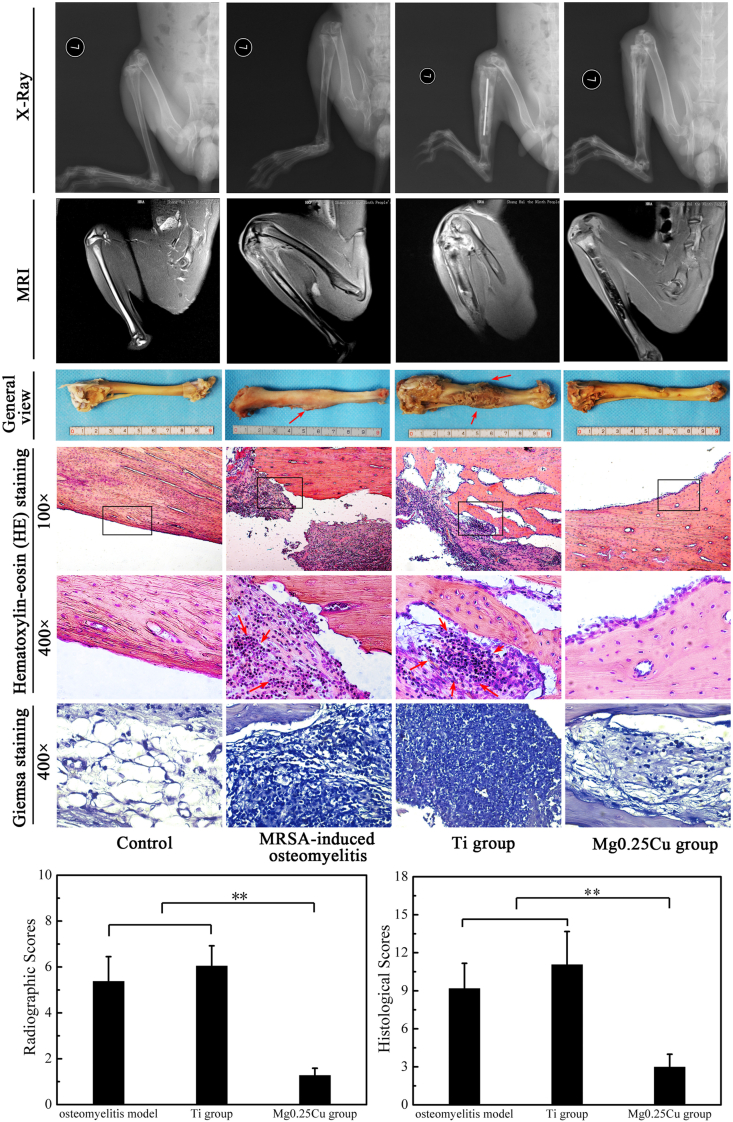

[32] |