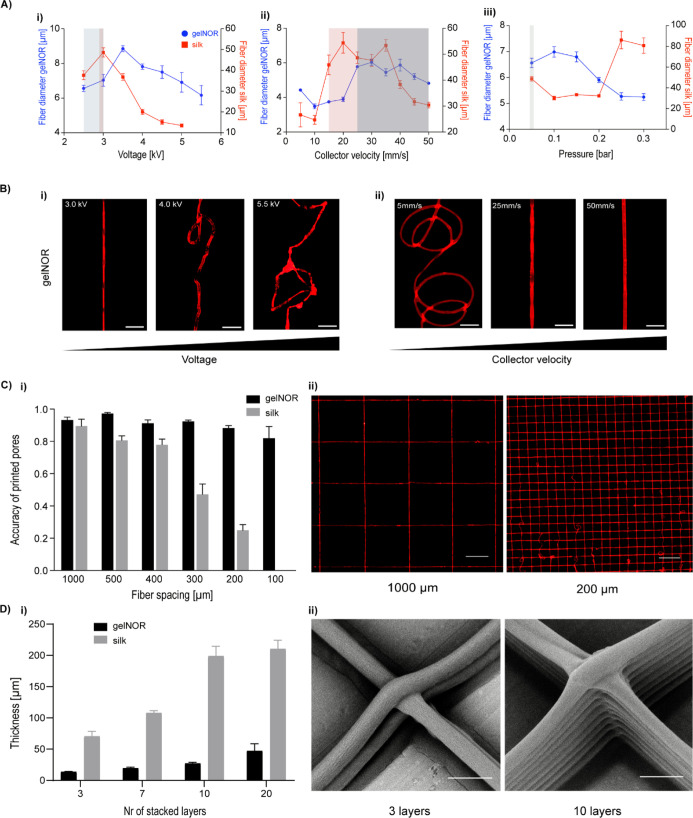

Figure 3.

Influence of key CEW processing parameters on fiber collection and 3D patterning for both cell-free gelnor and silk fibroin hydrogel systems. (A) Effect of (i) voltage, (ii) collector velocity, and (iii) air pressure on fiber diameter. Printability window is represented by background colors. (B) Representative microscopic images of the effect of increasing (i) voltage and (ii) collector velocity on fiber morphology for the gelnor hydrogel system. Scale bar: 50 μm. (C) Print fidelity of fiber hydrogel 3D scaffolds. (Ci) Accuracy of printed pores, Acc pore, as a function of scaffold pore size. Acc pore was determined using a relative value obtained by the ratio between the design and fabricated pore area. In the case of no deviation between the printed and designed pore areas, Acc pore = 1. (Cii) Representative images of printed scaffolds with pore sizes of 1000 and 200 μm for gelnor hydrogel. Scale bar: 500 μm. (D) Scaffold thickness as a function of the number of stacked hydrogel layers. (Di) Final scaffold thickness and (Dii) representative SEM images of scaffolds with 3 and 10 layers showing perfectly stacked hydrogel fibers at the vertices of squared pores. Scale bar: 10 μm.