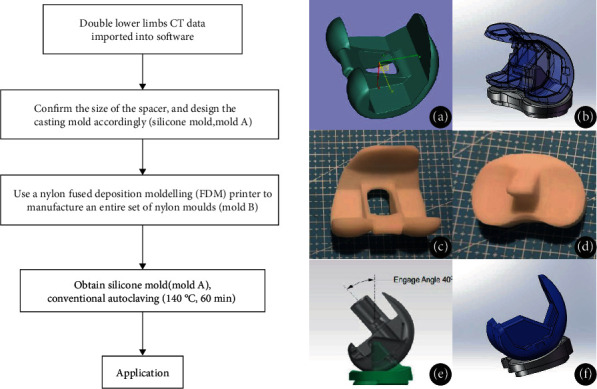

Figure 1.

The production process and design of 3D printing assisted articulating spacer. (a) The spacer imitates the geometry of a permanent artificial knee joint, and the anterior condyle is thinned to reduce anterior patellar pressure. (b) The diseased carriage is extended, deepened, and lengthened, enabling the patella to enter the carriage movement early. Therefore, patients are less likely to have adverse reactions such as dislocation and ringing after surgery. (c, d) Femoral component and tibial component of the 3D printing-assisted articulating spacer. (e) The tibial column is elevated to provide effective posterior stability. (f) The tibial platform sliding interface is designed with a deep disc, allowing a range of motion for joint stability.