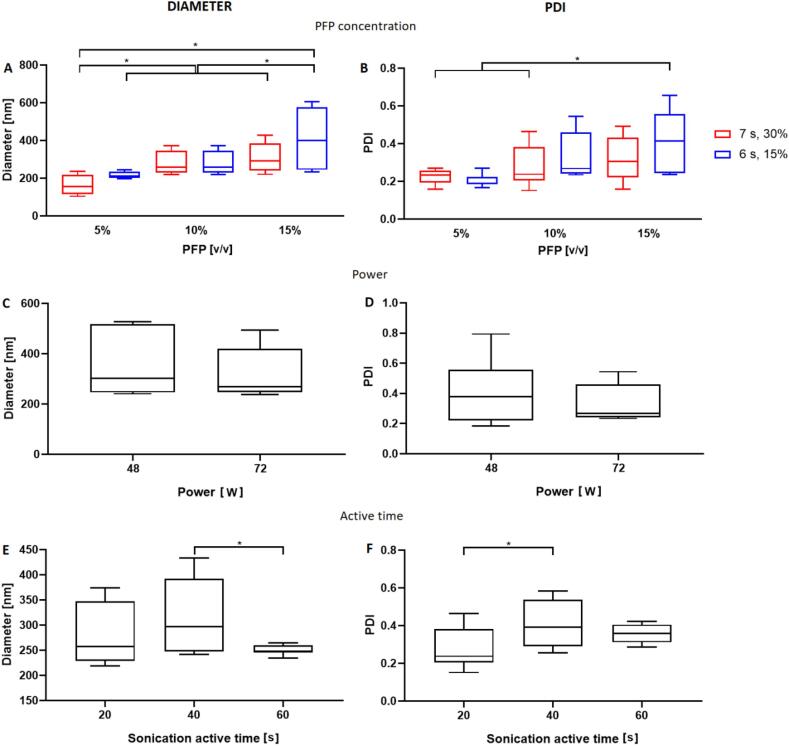

Fig. 1.

Effects of production parameters on ND size and size distribution. A,B) Effect of the quantity of PFP and the pulse length of the second sonication on ND size and size distribution. In these experiments, NDs were produced by applying a pulsed sonication of 20 s at 72 W, with either a pulse of 7 s and 30% duty cycle (red) or a pulse of 6 s and 15% duty cycle (blue). On the left, boxplots show the ND diameter distribution (just after production). NDs produced with 5% (v/v) PFP and a longer pulse were statistically different from the other groups tested (*p < 0.05). On the right, boxplots show the PDI of NDs (just after production). C,D) Effect of second sonication power on ND size and size distribution. Sonication was performed for a total active time of 20 s, with a pulse of 7 s and 30% duty cycle. On the left, boxplots show the distribution of ND diameter after production, for NDs obtained with sonication at power of 48 W and 72 W. An increase in the sonication power resulted in a decrease in ND mean size and size distribution. On the right, boxplots show the PDI of ND after production, for NDs obtained with sonication at power of 48 W and 72 W. Increasing the sonication power led to a reduced polydispersity index. E,F) Effect of second sonication active time on ND size and size distribution. Sonication was performed in a pulsed mode with a pulse of 7 s and 30% duty cycle. On the left, boxplots show the diameter distribution of NDs produced with different durations of the second sonication. There was a statistical difference between NDs produced with a sonication of 40 s and 60 s (*p < 0.05). On the right, PDI of NDs produced with different durations of the second sonication. There was a statistical difference between NDs produced with a sonication of 20 s and 40 s (p < 0.05). Three different samples were tested for each experimental condition reported in the graphs (N = 3). (For interpretation of the references to colour in this figure legend, the reader is referred to the web version of this article.)