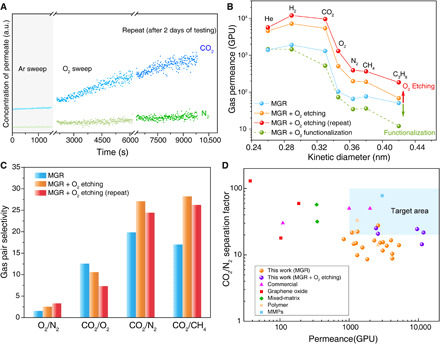

Fig. 4. Gas separation performance of N-SLG prepared by MGR followed by in situ O2 treatment at 200°C.

(A) CO2 and N2 evolution in the permeate side during the in situ etching. (B) Gas permeance at 25°C as a function of the kinetic diameter from the as-prepared N-SLG membrane, from those subjected to the in situ O2 treatment, and from that subjected to O3 at 25°C for 2 min. The term “repeat” refers to repeating the in situ O2 treatment after 2 days of gas permeance testing. (C) Comparison of the gas pair selectivity data at 25°C of the as-prepared N-SLG membrane with those subjected to the in situ O2 treatment. (D) Comparison of the CO2/N2 mixture separation performance from the membranes prepared in this study with the state-of-the-art membranes for postcombustion capture. The target area refers to the membrane performance needed to surpass the energy efficiency of the amine-based absorption process (6, 7). MMPs, metal-induced ordered microporous polymers.