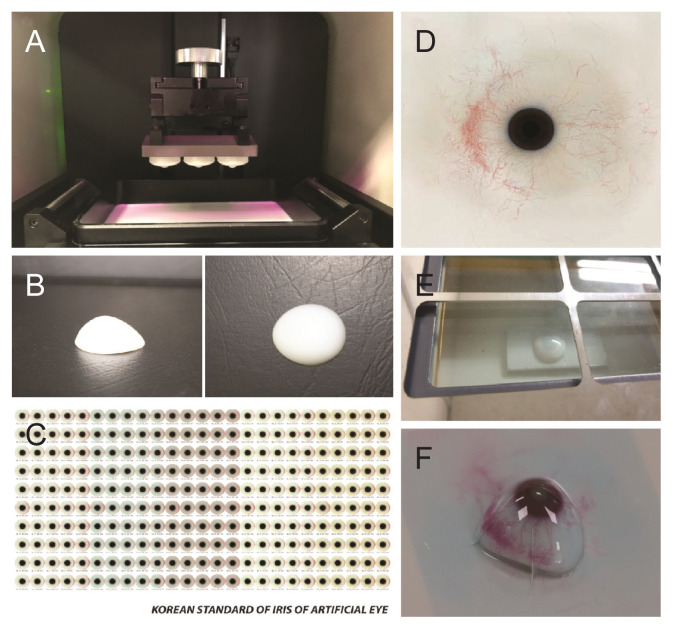

Fig. 1.

Process of sublimation transfer printing for three-dimensional (3D) ocular prosthesis creation. (A) The ocular prosthesis manufacturer selects a scleral 3D modeling file with customized details of the patient’s conjunctiva and then manufactures the sclera product using a digital light-processing 3D printer. (B) After washing the impurities remaining on the surface of the sclera product with alcohol, the sclera product is completed. (C) The graphic data that most closely matches the image of the patient’s healthy eyes from standardized color sets are selected to match the iris color and pattern of the patient. (D) After printing the graphic data on a transfer paper with a sublimation transfer inkjet printer, the transfer paper is dried at room temperature. (E) The sclera product is placed in the center of the sublimation transfer machine table, the center of the transfer paper is aligned to the marked pupil center of the sclera, and sublimation transfer printing is initiated. (F) The final product of the 3D ocular prosthesis with sublimation transfer technique.