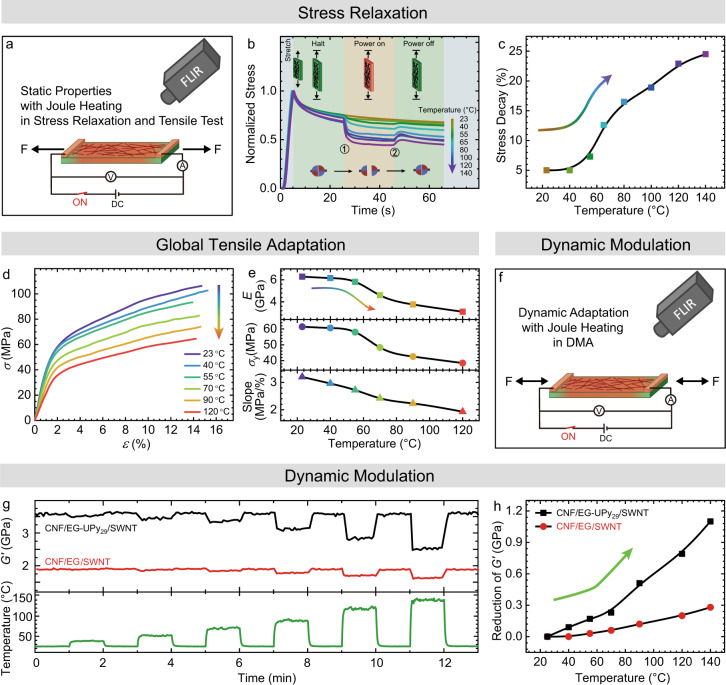

Fig. 3. Electricity-adaptive mechanical properties in CNF/polymer/SWNT (50/50/10) nanocomposites studied under Joule heating.

a Illustration of the setup of electricity-adaptive properties testing in stress relaxation and tensile tests. The action area of the film is 5.5 × 2 mm. b, c Electricity-adaptive stress relaxation. b Temporal evolution of the stress of CNF/EG-UPy29/SWNT (50/50/10) nanocomposites. This contains four steps: Stretching to strain = 1.0 ± 0.1%; relaxation for 20 s at ambient condition (power off); relaxation for 20 s with power on and voltage-controlled Joule heating; power off and further relaxation for 20 s. c Stress decay as a function of temperature with applied voltage from 25 to 45 s (indicated in (a) as from ① to ②). The stress decay defined as the relative reduction in stress during 20 s of power turn-on: (σ1 − σ2)/σ1. d, e Electricity-adaptive global tensile properties. d Stress–strain curves of CNF/EG-UPy29/SWNT (50/50/10) nanocomposites under Joule heating and varying temperature. e From top to bottom, the panels show the corresponding E, σy, and the slope of inelastic deformation region as a function of temperature. f–h Dynamic in situ modulation of the mechanical properties under Joule heating. f The illustration of the setup of electricity-adaptive properties testing inside a DMA using oscillatory deformation. g Temporal evolution of storage modulus, G′, tested using DMA with varied voltage to control the temperature, which shows the reversible and electricity-adaptive properties of the bioinspired nanocomposites. The black and red lines are the G′ for CNF/EG-UPy29/SWNT (50/50/10) and CNF/EG/SWNT (50/50/10), and the green line the corresponds to the temperature during the tests. h The reduction of G′ as a function of temperature extracted from (d).