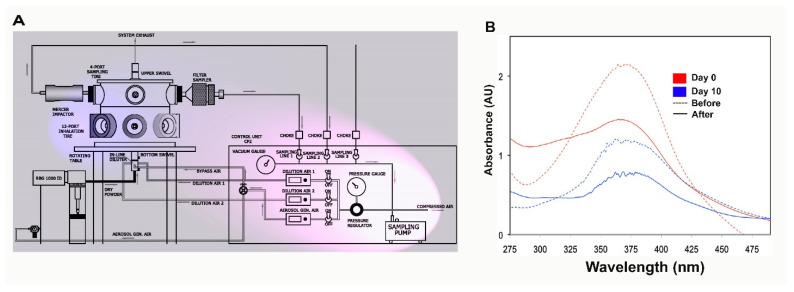

Figure 1.

The design of the semi high-throughput aerosolization device for in vivo treatment of small animal models and formulation characterization. (A) The control module (pink shade) is comprised of a precision sampling pump, a controlled source of compressed air, which feeds directly to the aerosol generation line or other lines for dilution air when it is necessary to thin the aerosolized solution. The aerosol chamber (blue shade) is equipped with a polyvinyl fluorinated polymer cross-flow atomizer (single-pass atomizer) atomizer on the bottom of the chamber. The generated aerosol will be conveyed through an L-shaped conveyor, which projects directly to a stainless steel inhalation chamber designed to collect the aerosol and distribute it equally to gasket-tight sealed outlets capable of serving 5 animals simultaneously; (B) testing the stability of Thioflavin S (ThioS) formulation in dd water at the concentration of 2% (w/v). The solution was split into two batches; one was immediately tested. The other was kept in the dark at room temperature and tested with an identical procedure 10 days later. The absorbance of ThioS at lambda max 374 nm in water was assessed using a spectrophotometer before and after passing the solution through the atomizer on day 0 (red curves) and day 10 (blue curves). The dash lines indicate the solution before being aerosolized, while continuous lines represent the solution after being aerosolized.