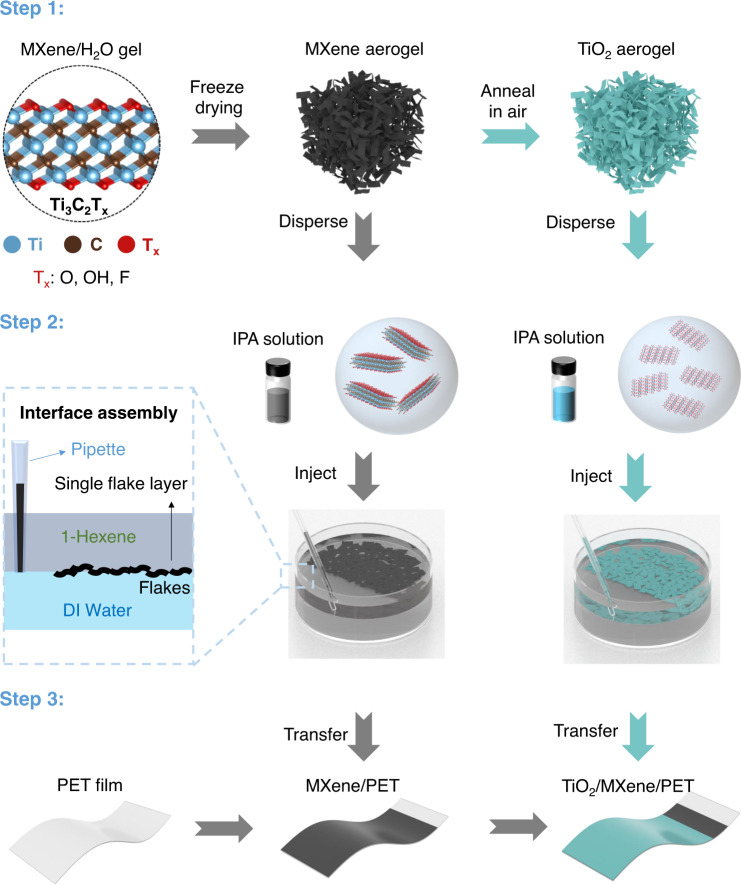

Fig. 1. Fabrication process of TiO2/Ti3C2Tx heterostructure on a flexible substrate.

Step 1: MXene (Ti3C2Tx, crystal structures in the left panel, is drawn by Vesta software) aerogel is obtained by freeze drying of the Ti3C2Tx nanosheets dispersion and the derived TiO2 aerogel is obtained by annealing the MXene aerogel in air at 400 °C. Step 2: Ti3C2Tx and TiO2 2D nanosheets are dispersed, respectively, in IPA, injected into the interface between hexene and DI water, and self-assembled into nanometer-thick Ti3C2Tx and TiO2 films. Step 3: the thin films are transferred onto a flexible substrate (e.g., PET) in a layer-by-layer fashion to realize the TiO2/MXene heterostructure, where the TiO2 layer serves as the electrochromic component, and the MXene layer serves as the transparent electrode.