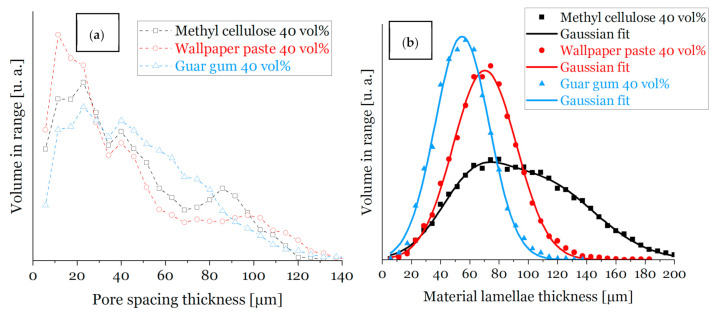

Figure 7.

Distributions of the width of material lamella and pore spacings of sintered foam samples from dispersions with 40 vol.-% solid load measured by µ-CT; distribution of the (a) pore spacing thickness and (b) material lamella thickness of sample struts from sintered foam samples, respectively.Freeze-dried replica foams with starch flour as a thickening agent made from 30 vol% alumina dispersions broke during PU burnout; their stability was insufficient, most likely due to the high amount of lamellar pores within the foam structure.