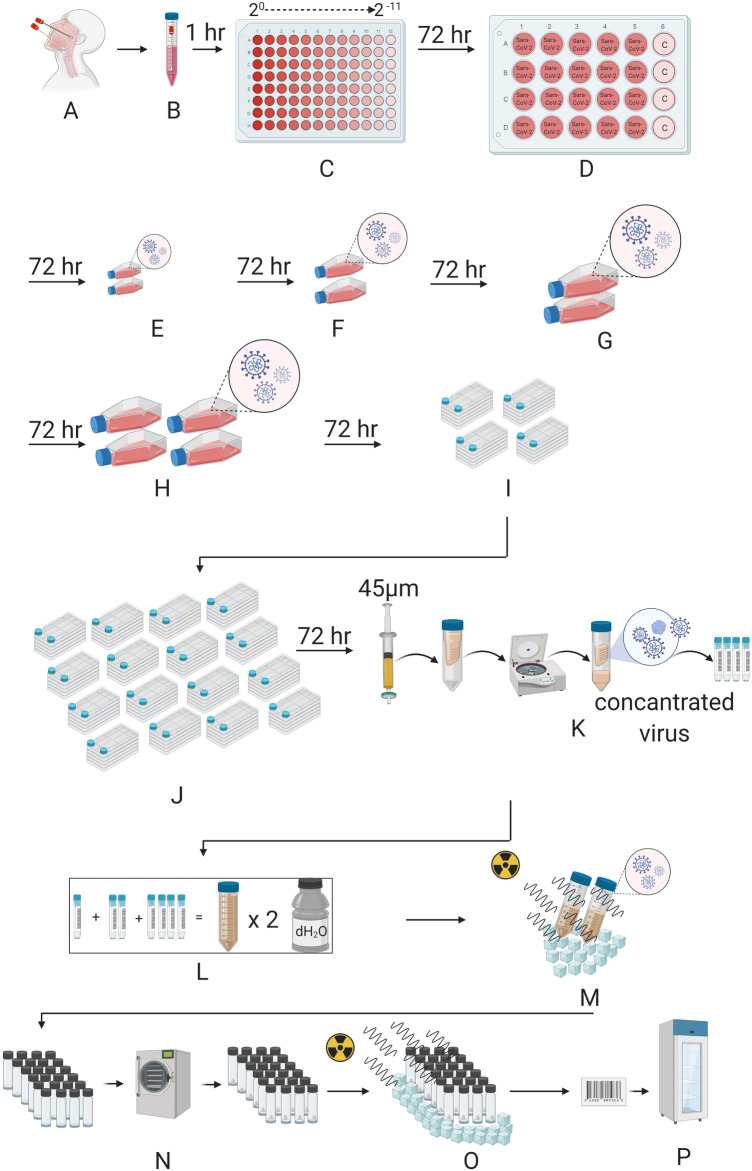

Figure 1.

Representation of Gamma-irradiated inactive lyophilized SARS-CoV-2 manufacturing. (A) Nasopharyngeal and Oropharyngeal samples were taken. (B) Sample came to the laboratory in a 2–8 C transfer solution. (C) The virus was distributed by making serial dilution (up to 2−11) onto Vero cells. Viruses were transferred to (D) a 24-well plate (E) T-75 flasks F. T-175 flasks (G) and (H) T-300 flasks with a confluent with Vero cells by increasing culturing surface area. Next, the propagated virus was transferred to (I) four and (J) sixteen multi-layered flasks with a confluent with Vero cells. (K) The total virus solution was then passed through a 45 µm filter, the virus was concentrated by centrifugation in a special tube with a 100 KDa filter. The concentrated virus was stored at -80 °C before irradiation. (L) All concentrated viruses obtained are pooled and washed two times with distilled water for diafiltration in a 100 KDa concentrator. (M) The concentrated virus mixture was inactivated by irradiation at 25 kGy in dry ice. (N) Inactivated virus is lyophilized after dose adjustment. (O) The lyophilized virus mixture is sterilized by irradiation at 25 kGy in dry ice. (P) The lyophilized bottled inactive SARS-CoV-2 vaccine is labeled and stored at 4 °C.