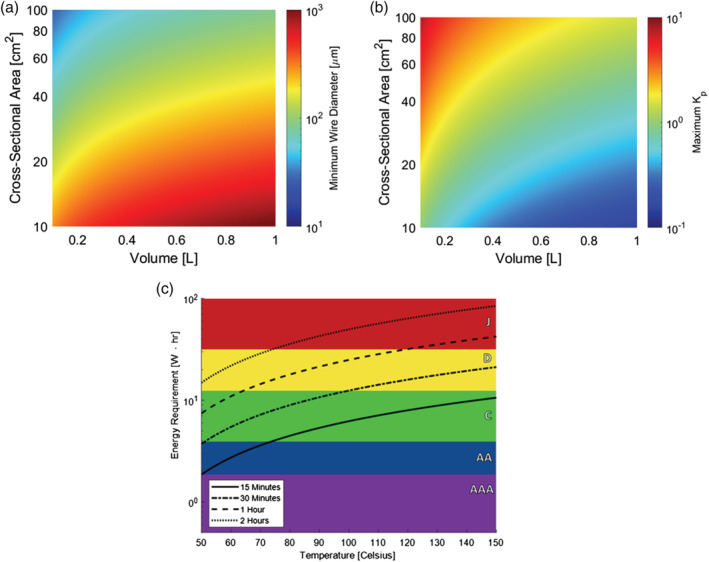

FIGURE 6.

(A) Minimum allowable mesh diameter as a function of mask volume and cross‐sectional area. The threshold mesh diameter induces a pressure drop of 60 Pa L−1/s at the maximum breath flow rate of 0.4 liters per second. Mesh solidity is set to 0.1, with wire spacing equal to 3.2 times the wire diameter. Coarser meshes are required in larger masks to obey the pressure drop constraint, while meshes with higher cross‐sectional area (and lower aspect ratio) can tolerate finer meshes without exceeding the maximum pressure drop. For the final design case, with a volume of 300 ml and a cross‐sectional area of 50 cm2, a mesh size of 0.1 mm is ideal. (B) Maximum achievable partition coefficient, K p , as a function of mask volume and cross‐sectional area. The partition coefficient is calculated as the ratio of the adsorption rate to the desorption rate, where k ads is calculated from fiber efficiencies while a conservative value of k des = 1 s −1 is assumed. It is likely that a mask with a volume of 300 ml and an aspect ratio of 3 can achieve a K p of 2, allowing for 3‐log reduction in SARS‐CoV‐2 transport. (C) Energy requirement of 300 ml mask vs. average temperature. The energy requirement for a given amount of time is compared against the total power supply of standard commercial batteries that have the following power capacities and weights 47 : AAA, 1.87 W h and 12 g; AA, 3.9 W h and 24 g; C, 12.3 W h and 65 g; D, 31.5 W h and 135 g; and J, 540 W h and 272 g [Color figure can be viewed at wileyonlinelibrary.com]