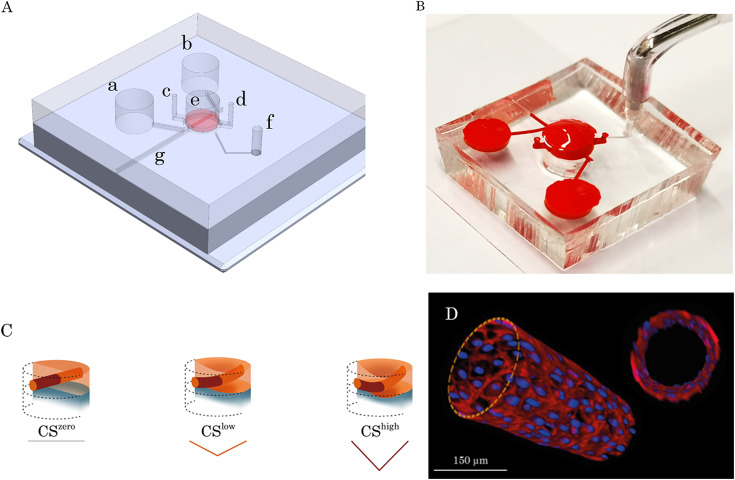

FIG. 12.

Microfluidic chip for the 3D dynamic microvasculature. (a) Schematic illustration of the multilayer dynamic microvasculature platform. The main compartments of the microfluidic chip are shown in the picture. (a) and (b) Inlet and outlet reservoirs for cell seeding and medium exchange, (c) and (d): inlet and outlet ports for fibrinogen solution loading, (e) central chamber for the fibrin gel layer incorporating a 3D vasculature, (f) access port to the bottom layer to be connected to the pump for applying negative pressure, and (g) is the groove where the needle can be inserted and removed (a small piece of tape was used to seal this groove to avoid any leakage of the fluid from the chip). (b) The PDMS platform was plasma bonded to a microscope slide and filled with red food dye for better illustration of the compartments. It comprised two main layers separated by a 100 μm-thick PDMS membrane. The top layer contained a central circular chamber to insert a needle from the adjusted access port and load fibrin gel to generate a tube in the middle of the gel layer. The bottom layer had a circular chamber connected to the breather access port through a microchannel. (c) Microvasculature under different magnitudes of CS. The deflection of the membrane was achieved by applying a negative pressure from the pump, which leads to the deformation of the gel layer including the vasculature. Two different magnitudes of cyclic stretch were investigated to deflect the vasculature. (d) Illustration of the 3D microvasculature formed in the middle of the fibrin gel layer.