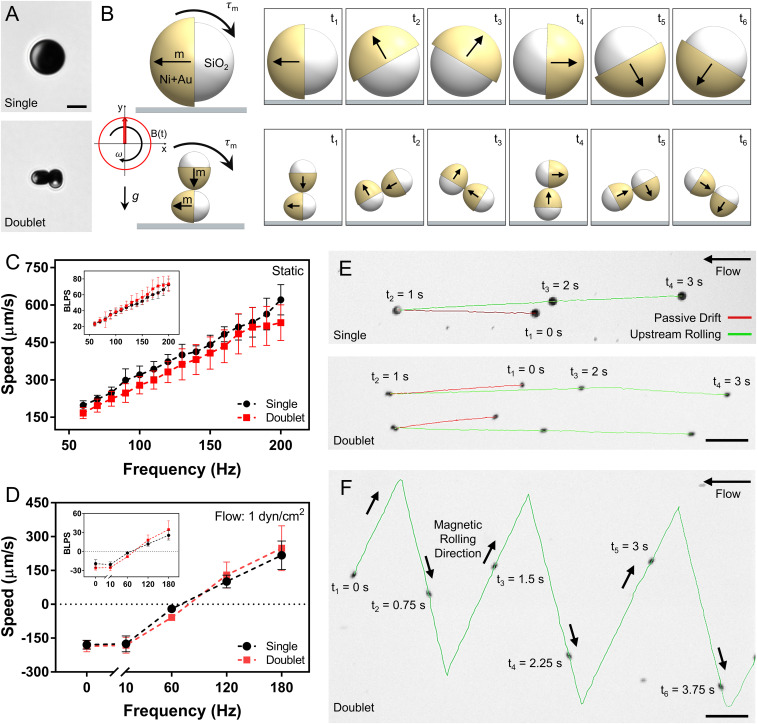

Fig. 2.

Rolling characteristics of magnetically actuated single and doublet microrollers on flat glass surfaces in a stagnant PBS (1×). (A) Optical microscopy images of single and doublet microrollers. Single microrollers are composed of 7.8 µm diameter silica microparticles sputtered with 1,000 nm thick Ni and 20 nm thick Au nanofilms. Doublet microrollers are composed of magnetically self-assembled 2 × 4 µm diameter silica microparticles each sputtered with 1,000 nm thick Ni and 20 nm thick Au nanofilms. (Scale bar, 5 µm.) (B) Under a rotating magnetic field, microrollers experience a torque (τm), which results in rotation of the microrollers and hence propulsion. Black arrows show the magnetization direction of the Ni film. g indicates the gravity direction. (C) Average speed of microrollers on glass depending on actuation frequency (10 mT). Single and doublet microrollers can reach speeds up to 600 and 550 µm/s, respectively. Both groups are similar in terms of BLPS (Inset). Error bars represent the SD of the mean. (D) Frequency-dependent upstream propulsion speed of microrollers in PBS flow at 1 dyn/cm2. Below 60 Hz, both microroller designs fail in upstream propulsion and start drifting in the flow direction. Error bars represent the SD of the mean. (E) Time-lapse images of the microrollers first drifting in the flow direction (red line, until t2 = 1 s) and then rolling (at 180 Hz, 10 mT) against the flow (green line, until t4 = 3 s) at 1 dyn/cm2. (Scale bar, 50 μm.) (F) Controlled trajectory of a doublet microroller in 1 dyn/cm2 flow. (Scale bar, 50 μm.)