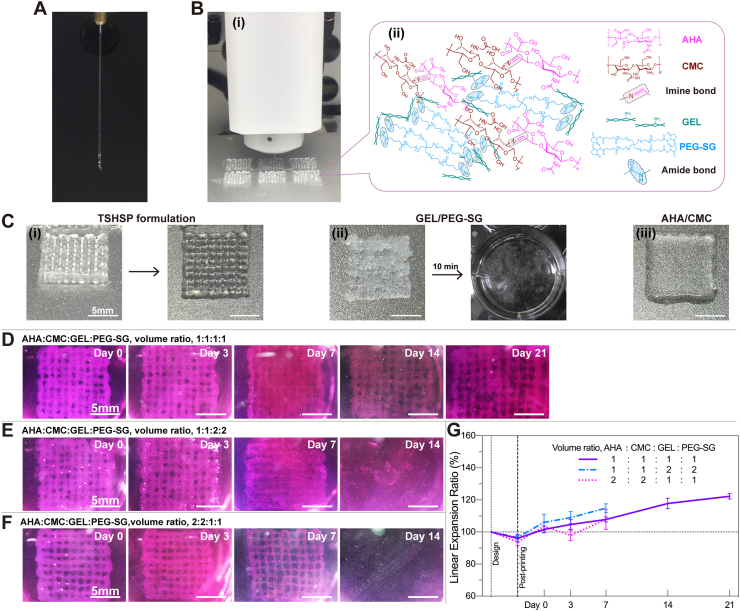

Fig. 5.

Printability of TSHSP hydrogels and subaqueous durability of cell-free constructs. (A) Continuous extrusion of TSHSP hydrogel ink. (B) Printing of 6 grid structures at once with TSHSP ink (i) and schematic view of the gelation mechanism of TSHSP ink (ii). (C) Photographs of grid structure printed with TSHSP ink and its top view (i), laboriously printed non-integrated GEL/PEG-SG structure that shattered after being immersed in PBS for 10 min at room temperature (ii), and printed bulk AHA/CMC constructs (iii). (D)–(F) Subaqueous images of the integrity of cell-free constructs printed with different proportions of TSHSP formulations during incubation. (G) Printing fidelity and dimensional change profile of cell-free constructs compared to design (n = 3, error bars, mean ± SD).