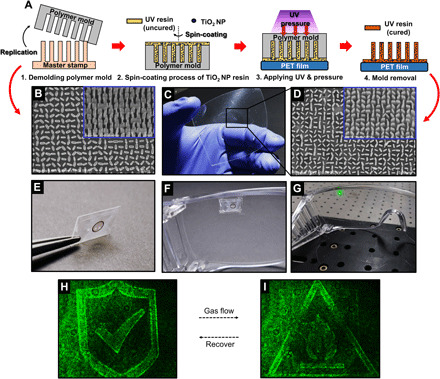

Fig. 4. Demonstration of a flexible LC-MS gas sensor and an integrated safety device.

(A) Schematic illustration of a one-step nanocasting fabrication process of a flexible metasurface. The master stamp fabricated with 1 μm-height a-Si:H metasurface is chemically treated to reduce the adhesive strength for easier demolding process. The detached polymer mold is reusable. (B) SEM image (top view) of the silicon master stamp for the nanocasting process. The inset shows a tilted view image. (C) Photograph of the resulting flexible metasurface. (D) Corresponding SEM image (top view) of the NP-resin composite (NPC) metasurface. The inset shows a tilted view image. Photo credit: Inki Kim, POSTECH. (E to G) Flexible and conformal holographic metasurface gas sensor. The complete sensor, consisting of a flexible LC cell and an NPC metasurface, is attached onto the curved surface of safety goggles. Similar to the characterization of the a-Si:H metaholograms (Fig. 3), 532 nm wavelength RCP light is illuminated onto the flexible gas sensor to display holographic images. As seen in Fig. 5 (E and F), the LC cell and NPC metasurface are combined well. Photo credit: Inki Kim, POSTECH. (H and I) Experimentally demonstrated holographic safety signal in a normal condition and alarm signal upon an exposure of IPA gas. Compared to the a-Si:H device, the NPC metasurface not only has smaller critical dimensions and a larger height, meaning a higher aspect ratio, but also has some defects during the imprinting process. Thus, the diffraction efficiency and clearness of the holographic images are degraded.