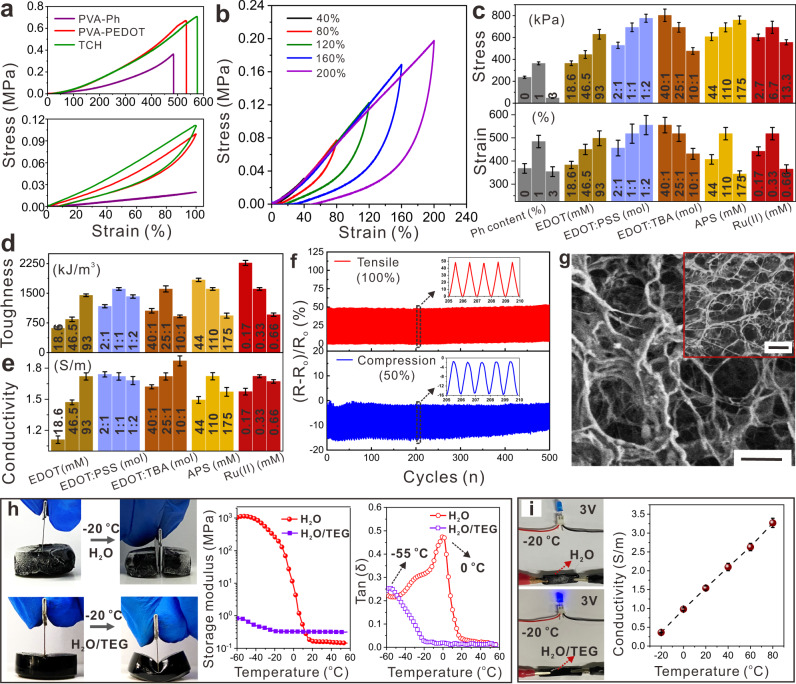

Fig. 3. Mechanical properties and conductivity tests of TCHs.

a Tensile tests of PVA-Ph, PVA-PEDOT (without TBA), and as-prepared TCH hydrogels. Stretching samples to maximum strains (top), strains of 100%, and then back to 0% (bottom). b Cyclic tensile tests of TCH to strains from 40 to 200%. The effect of preparation conditions on c mechanical property, d toughness, and e conductivity, respectively. f Resistance changes of TCHs in 500 cycles of stretching (100% strain) and compressing (50% strain) processes. g SEM image of freezing-dried TCHs after the cyclic tensile test in Fig. f. The inset image shows the sample before testing. Scale bars are 500 µm. h Mechanical (dynamic mechanical analysis) and toughness tests of TCHs and the hydrogel without TEG at −22 °C. i Optical images of powering LEDs at −22 °C by using hydrogels in h, and the conductivity variation of TCHs under different temperatures. TCHs were basically prepared at the following condition: [Ru(II)] = 0.33 mM, [APS] = 110 mM, [PVA-Ph] = 10 wt% with the phenol content of 1%, [EDOT] = 93 mM, [TBA] = 3.7 mM, [PSS] = 2 wt%, and TEG/H2O = 2/3. When evaluating the effect of one component on fabricating TCHs, other components were kept constant. Three samples were tested for each case in (c) and (d).