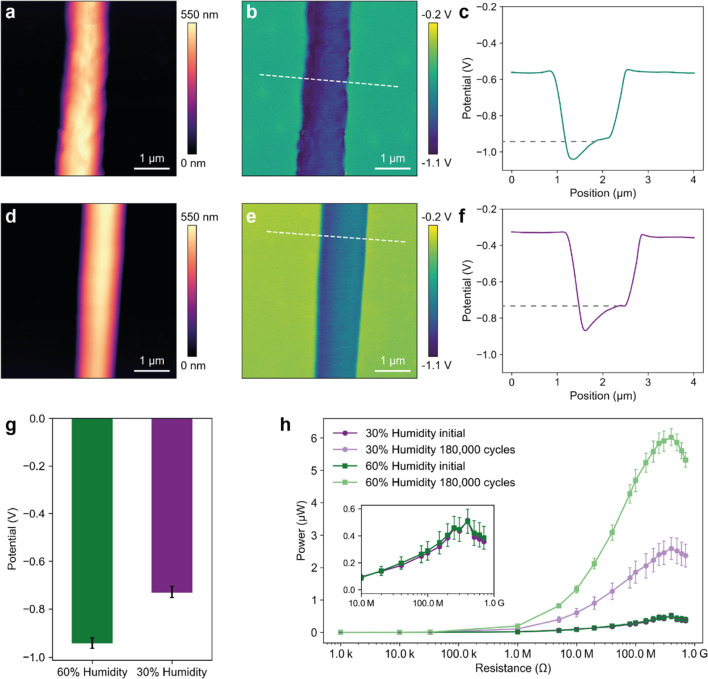

Figure 2.

Tailoring coating fabrication process for durability and high triboelectric performance. (a) and (b) Surface topography and surface potential of PVDF fibers produced using 60% relative humidity during the electrospinning process. The dotted line is the location of the line scan. (c) Line scan of the surface potential of 60% relative humidity fibers. The dotted line indicates the surface potential of the fiber. (d) and (e) Surface topography and surface potential of PVDF fibers produced using 30% relative humidity during the electrospinning process. The dotted line is the location of the line scan. (f) Line scan of the surface potential of 30% relative humidity fibers. The dotted line indicates the surface potential of the fiber. (g) Surface potential of the fiber mats. Multiple measurements across several fibers were recorded and averaged. (h) RMS power output measured across several external resistances of PVDF mats produced with 30 and 60% relative humidities. The samples were measured as fabricated and after 180 000 cycles to evaluate fatigue performance. The inset shows the initial measurements.