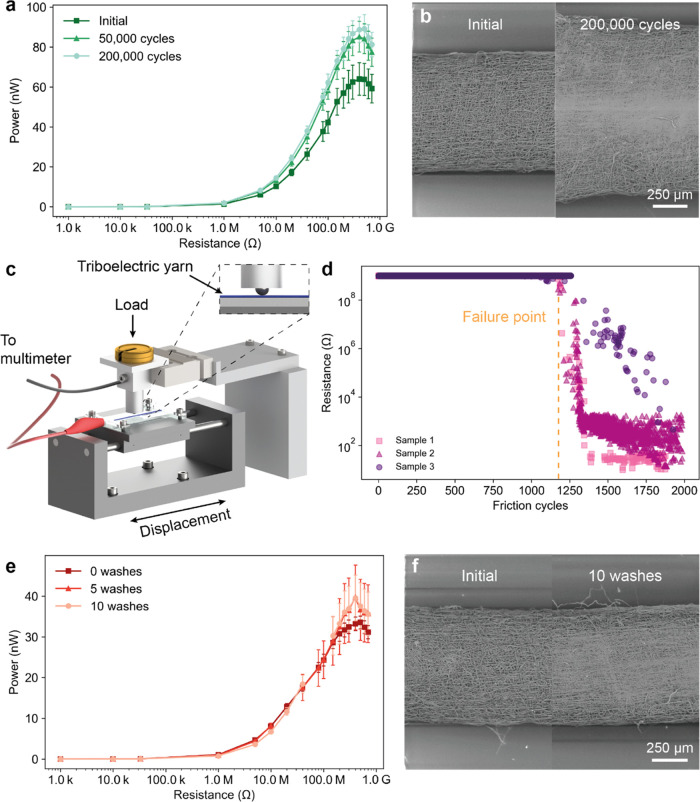

Figure 4.

Durability and washing resistance characterization of the triboelectric yarn. (a) Fatigue evaluation of the triboelectric yarn. RMS power output of the triboelectric yarn across different resistors. (b) SEM images of the same triboelectric yarn as fabricated and after 200 000 tapping cycles. (c) Schematic of the friction testing setup. The resistance between the triboelectric yarn and the steel ball is continuously measured as the ball rubs the sample. The inset shows the contact between the triboelectric yarn and the steel ball. (d) Resistance between the triboelectric yarn and the steel ball across friction cycles. The dotted line highlights the failure point, where the coating begins to delaminate. (e) Washing resistance evaluation of the triboelectric yarn. RMS power output of the triboelectric yarn across different resistors. (f) SEM images of the same triboelectric yarn as fabricated and after 10 washes.