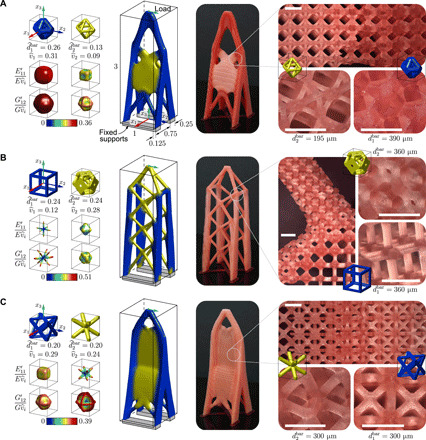

Fig. 1. Two-microstructural-material topology-optimized cantilever beams and multimicrostructure-embedded m-SLA parts.

Unit cells have (A) the same geometry and smooth/continuous transition by variable bar diameter, (B) different geometry with smooth/continuous transition by shape interpolation of the unit cell geometry, and (C) different geometry with smooth/continuous transition by hybrid unit cells composed of the basic unit cells. Directional tensile and shear moduli (based on homogenized properties) are plotted for each microstructural-material at the left of (A), (B), and (C). In all cases, the bulk materials are limited to a domain volume fraction of and for microstructural materials 1 and 2, respectively. Variables and are the unit cell bar diameter and volume, respectively, and is the manufactured bar diameter corresponding, in this case, to unit cells with edge length of 1.5 mm. In design, we model half of the domain and impose symmetry boundary conditions along the x2 − x3 plane. Printed cantilevers are 14.5 cm tall. Scale bars, 1.5 mm. Photo credit: Emily D. Sanders, Georgia Institute of Technology.