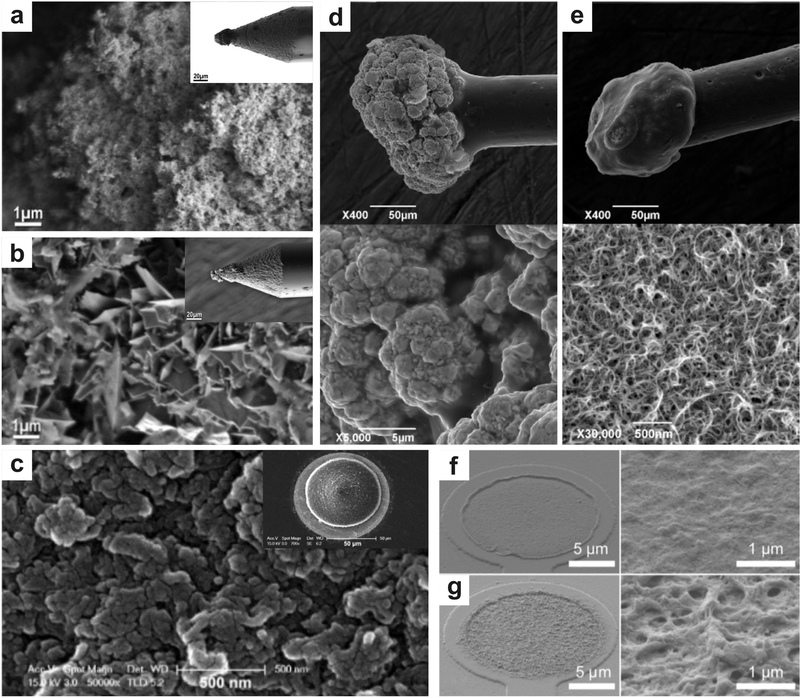

Figure 2.

Micrographs illustrate the myriad nanomaterial functionalization of neural interface electrodes. a-b) CNTs are grown on the tip of a micro-electrode via chemical vapor deposition and a gold-CNT composite is coated on an electrode via a metal plating technique, respectively Reproduced with permission.[49] Copyright 2011, American Chemical Society. CNTs have been deposited on microelectrodes to improve performance in neural recording by increasing the surface-area of the electrodes, which decreases impedance. The CVD electrode displays smaller surface structures and less lamellar structures when compared to the gold-CNT composite, resulting in a greater surface area and mechanical stability, c) Microstructure of PEDOT/MWCNT film deposited in galvanostatic mode on microelectrode (inset) for neuronal recording. Reproduced with permission.[65] Copyright 2013, Elsevier. This deposition technique resulted in longitudinal film growth with lessened electrical cross-talk, resulting in increased spatial resolution of the MEA. d-e) Gold particle and PEDOT:PSS-CNT coated microelectrodes and corresponding microstructures (below), respectively. Reproduced with permission.[51] Copyright 2016, Frontiers Publishing. PEDOT:PSS-CNT coated microelectrodes show a fine nano-structure as compared to the microstructure present on the gold particle coated electrodes. f-g) Morphology of PEDOT and PEDOT-CNT coated electrodes and their microstructures, respectively. Reproduced with permission.[66] Copyright 2012, Frontiers Publishing. The porous structure of the PEDOT-CNT coated electrodes results in a larger surface area, therefore a lower impedance, when compared to the electrodes coated in PEDOT alone.