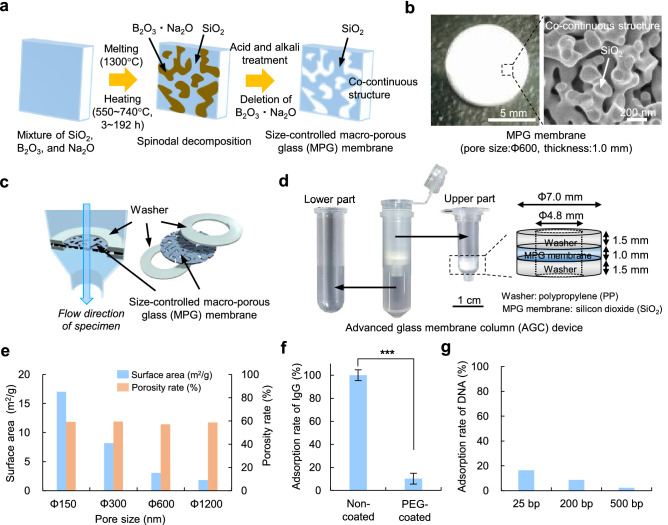

Figure 1.

Fabrication of the AGC device. (a) The production process for producing a size-controlled macro-porous glass (MPG) membrane. (b) A photograph and SEM image of the MPG membrane. (c,d) An image (c) and photograph (d) of the advanced glass membrane column (AGC) device. The MPG membrane in the AGC device was sandwiched by washers. The AGC device was composed of two parts (upper part: EV collection, lower part: supernatant collection). (e) The surface area (m2/g) and porosity rate (%) of the membranes (outside diameter: 7.0 mm, thickness: 1.0 mm, pore size: Φ150, Φ300, Φ600, Φ1200 nm). (f) The adsorption rate (%) of IgG in the non-PEG coated and PEG coated MPG membranes. (g) The adsorption rate (%) of dsDNA (25 bp, 200 bp, 500 bp) in the PEG coated MPG membranes.