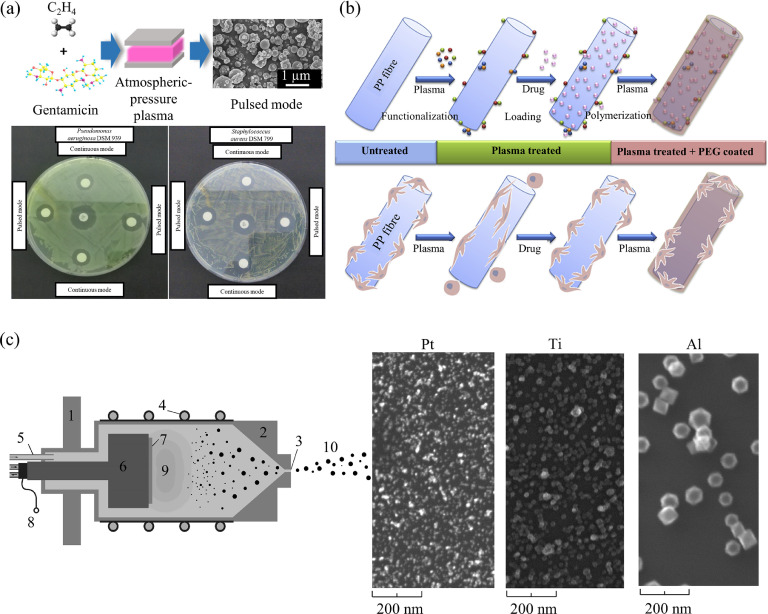

Fig. 6.

Representative examples of plasma engineering of drug/agent release coatings. (a) Single-step aerosol-assisted plasma deposition of gentamicin-containing coatings for drug release applications. Both continuous and pulsed mode plasma-exposed disks produced antimicrobial activity against Pseudomonas aeruginosa DSM939 and Staphylococcus aureus DSM799. The scanning electron microscopy (SEM) image shows the coating morphology which was prepared in the pulse mode for 20 min with 5 slm He, 20 sccm ethylene, and 10 mg/mL gentamicin solution. The scale bar shows 1 µm. [126], Copyright 2018. Adapted with permission from the American Chemical Society. (b) Multi-steps plasma surface engineering drug-loading processes and the relevant summary of the effects of the different plasma treatments performed to PP fibres on the adsorption of drugs and on the cell adhesion and morphology. [127], Copyright 2015. Adapted with permission from Elsevier. (c) Gas-aggregation plasma sputtering system (1-vacuum flange, 2-aggregation chamber, 3-exit orifice, 4-water cooling, 5-gas inlet, 6-magnetron, 7-target, 8-electrical connection, 9-plasma, 10-beam of nanoparticles) for composite surfaces production with the capability of metal ions release and hydrophobic/superhydrophobic behaviour. Scale bars are 200 nm. [128,129]. [128], Copyright 2012. Adapted with permission from Elsevier. [129], Copyright 2014. Adapted with permission from Elsevier.