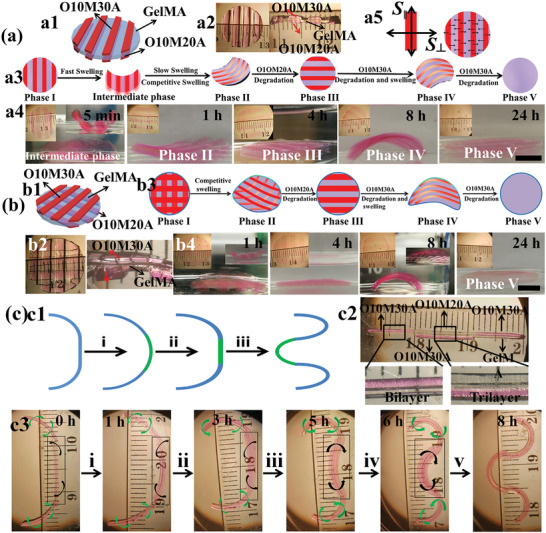

Figure 2.

Cell‐laden “smart” trilayer hydrogel fabrication and the programmed deformation. a) Overlapping parallel‐strip patterns on both surfaces of a GelMA hydrogel: a1) schematic of the sample design, a2) photographs of top view and section view of a prepared sample, a3) schematic illustrating the entire process of the construct shape changes over time, a4) photographs of the construct actual shape changes over time, and a5) the speculated mechanism for the formation of an intermediate phase. b) Parallel‐strip patterns orthogonal to each other on both the surfaces of a GelMA hydrogel: b1) schematic of the sample design, b2) top view and section view photographs of a prepared sample, b3) schematic illustrating the entire process of the construct shape changes over time, and b4) photographs of the construct actual shape changes over time. All samples were cultured in GM at 37 °C, and GM was replaced with PBS before taking images for clarity. Insets in (a4) and (b4) on the top left corner show the constructs from the top view, and insets on the top right corner of some images (a4: 5 min; b4: 1 and 8 h) show the constructs from the side view. c) Biomimicry of branching morphogenesis: c1) schematic of branching morphogenesis of lung, step i: formation of a nascent bud, and steps ii and iii: cleft formation and terminal bifurcation; c2) photomicrograph of a typical cell‐laden discrete trilayer hydrogel bar designed to undergo branching morphogenesis; c3) photomicrographs of the 4D hydrogel system mimicking the process of lung branching morphogenesis by the discrete trilayer cultured in GM at 37 °C. Images were taken after replacing the GM with PBS for clarity. The two OMA layers were co‐crosslinked with methacryloxyethyl thiocarbamoyl rhodamine B (0.005%) for visualization. Scale bars indicate 4 mm.