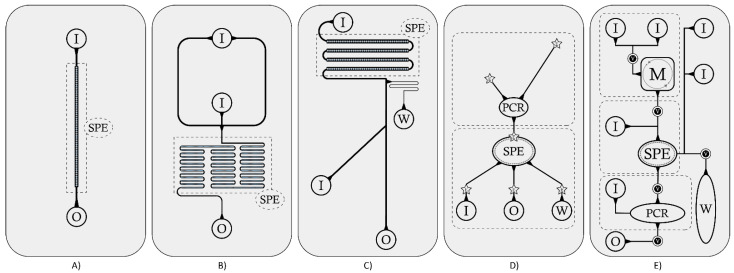

Figure 2.

Schematization of chip structures from a simpler to a more complex design. (A) Chip with a simple linear structure: the main flux circulation is driven into a single microchannel through an inlet and an outlet port. The extraction domain consists of a part of microchannel with a packed adsorbent matrix polymerized inside it [10,23,24,46,75]. (B) Chip with a coil-shaped microchannel: the extraction domain is composed of a long microchannel with an increased surface/volume ratio of the adsorbent matrix packed inside it [31,42,61,69]. (C) Chip with a main microchannel and a side arm: sample and reagents are loaded in separate steps through different ports. Flux direction can be modulated at each phase by pressure application [9,25,33,37,76]. (D) Chip with electrokinetic motion: sample and pre-stored reagents are driven by voltage modulation into the extraction and amplification domains [65]. (E) Chip with a multi-domain design: each step of the sample processing is managed by valve activation. Generally, complex chips allow a whole sample treatment, from the lysis, the NA extraction with the development of various extraction techniques and, in some cases, the sample post-processing [27,35,39,44,47,66,67,71]. I = Sample or reagents inlet; O = Sample outlet; SPE = Solid-phase extraction domain; W = Waste chamber; PCR = Amplification chamber; E = Electrodes; V = Valves; M = Mixing or lysis chamber.