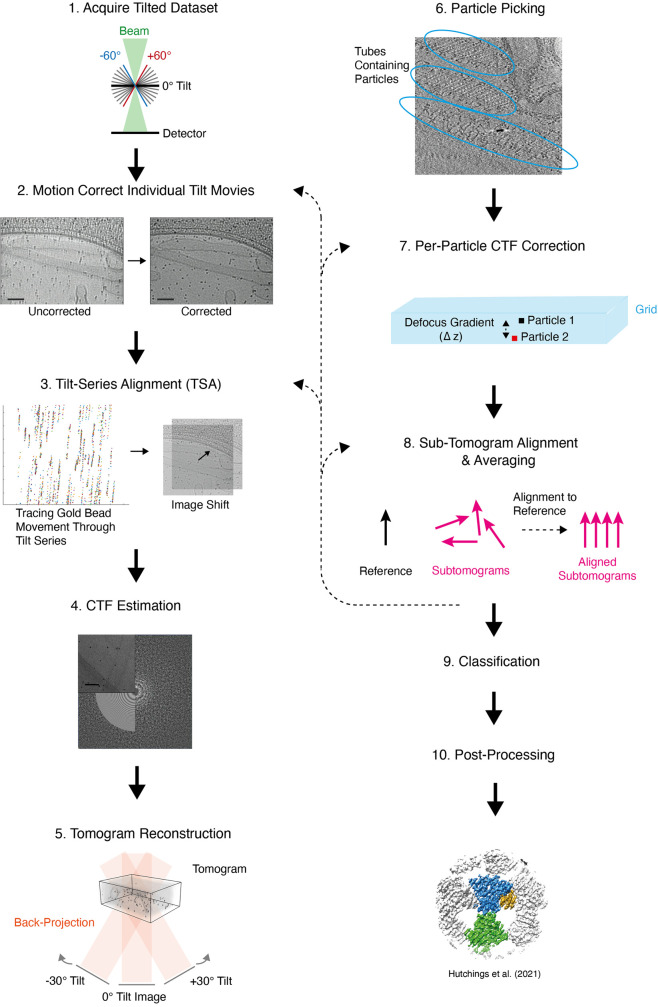

Figure 1. Overview of a typical cryo-ET with STA data processing workflow.

Note that several steps can be iteratively refined and/or returned to at a later point in the workflow. The steps that are most commonly iterated are indicated by dotted arrows. The order in which these steps are carried out may vary. (1) During data collection, 2D movies of the sample are captured at fixed points over a range of tilt angles (typically ±60°). (2) Each individual movie is motion-corrected, dose-weighted, and averaged to form a series of 2D images hereafter referred to as a tilt-series. (3) The position of the grid in each image is refined by tracing the position of fiducial markers (usually gold beads) throughout the tilt-series (left) and transforming individual images (right) to ensure a smooth fiducial marker trajectory. This process is known as tilt-series alignment (TSA). (4) Contrast transfer function (CTF) estimation is then carried out for each 2D image in the tilt-series by fitting a CTF model (bottom left) to the Fourier transform (right) of the real image (top left). (5) The 2D images in the tilt-series are backprojected to form a 3D volume, otherwise known as a tomogram. (6) Particles of the protein of interest are picked within the tomogram. Small 3D volumes, or subtomograms, containing one or more particle(s) are then extracted. (7) CTF correction can be carried out at this point or elsewhere in the workflow. (8) The subtomograms are aligned to a reference and averaged. This average is used as a new reference until the alignment reaches convergence and a structure with maximal resolution is generated. The resolution of the resulting structure can be assessed by ‘gold-standard’ Fourier shell correlation (FSC), spectral SNR methods, or local resolution estimations. (9) Conformational and compositional heterogeneity can be assessed by classification of subtomograms after or during STA. This may lead to the generation of multiple structures with different compositions or conformations. (10) Optionally, a range of post-processing techniques can then be used to improve the quality of the structure such as sharpening. The data presented here was generated by Hutchings et al. [19,20].