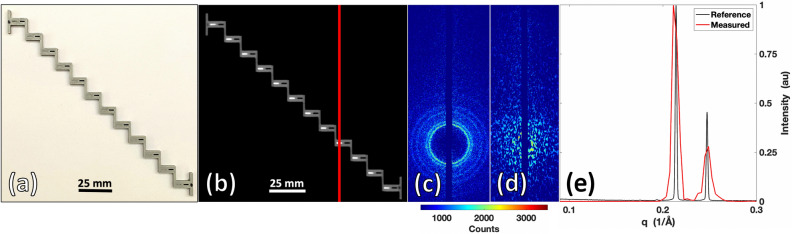

Figure 2.

3D printed phantom with 1 × 4 × 3 mm3 wells for measuring aluminum powder in the X-ray fan beam coded aperture imaging system. (a) Photograph of the phantom. (b) X-ray transmission scan of phantom, showing aluminum powder in the left well of each step with right wells empty. (c) XRD scatter rings of aluminum (empty PLA well subtracted) without a coded aperture, acquired when fan beam was at the location of the red line in (b), showing distinct rings with higher intensity scatter of X-rays. (d) Encoded XRD scatter (from aluminum and PLA) passing through a coded aperture, creating spatially unique modulations that can be utilized to reconstruct XRD spectra along the fan beam. (e) XRD spectra of aluminum powder measured by inputting the data from (d) into a reconstruction algorithm based on the modeled physics of the imaging system, demonstrating accurate identification and measurement of aluminum in the phantom. MATLAB (v2020a) was used for the visual display of all X-ray data presented within this figure and all other figures.