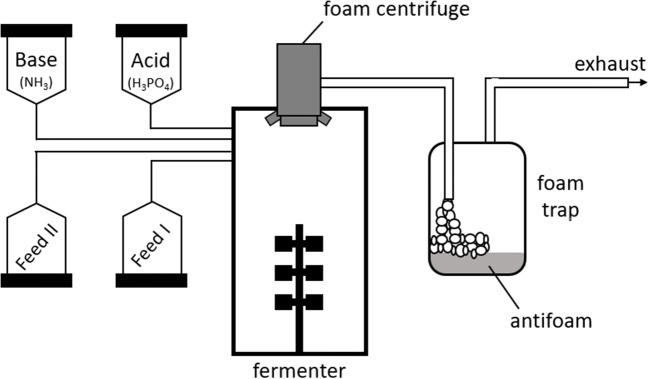

Fig. 1.

Illustration of the bioreactor set-up. Shown is the fermenter in the middle with a foam centrifuge at the exhaust port. The exhaust pipe was bypassed through canister used as a foam trap with antifoam agent Contraspum A4050 in 3 L of water. The air could freely leave the canister through a second exhaust port leading to the exhaust filter. Four scales were used to monitor pH control as well as feeding solutions. In case of a two-feed process, one of the feeds was swapped after the first fed-batch phase for the second glucose feed