Abstract

In this work, two types of flour from peach palm fruits (Bactris gasipaes) were prepared to be used to produce cookies: one with the whole fruit (pulp + peel) and another one with only the pulp. Analyses of proximate composition, physicochemical and hygroscopic behaviour were carried out in both flour, as well as sensory analysis of the produced cookies. Both the types of flour did not differ statistically in total lipids, total carbohydrates and ashes (p > 0.05). Among the mathematical models tested for the prediction of the hygroscopic behaviour of both flour, Halsey model showed the best fit to the experimental data (R2 = 0.99 and P<10%). The cookies produced with both types of peach palm flour presented low moisture (4.9–6.2%), high lipid content (25.56–26.37%) and total carbohydrates (59.10–61.84%), resulting in a product with high total energetic value (501.8–502.8 kcal/100 g). Based on the results of acceptance test, both cookie formulations presented good sensory acceptance (>70%). The purchase intention inquiry showed that the cookie prepared with the whole fruit flour presented the highest percentage of purchase intention (85%), which demonstrate that the use of peach palm peels in the development of new food products represent an excellent alternative for the use of by-products.

Keywords: Bactris gasipaes, Amazonian fruit, Hygroscopicity, Bakery product, Sensory analysis

Bactris gasipaes; Amazonian fruit; Hygroscopicity; Bakery product, Sensory analysis.

1. Introduction

Peach palm fruits (Bactris gasipaes Kunth) are native to Amazonia biome, belong to the Arecaceae family, and they occur as wild or domesticated varieties whose genetic differences are mainly influenced by their local of cultivation and exhibit different sensory characteristics, such as taste and colour (Ferreira and Pena, 2003). The fruits were reported to contain high levels of starch (≈72%), lipids (≈8–36%) (Leterme et al., 2005; Carvalho et al., 2013), and very high contents of carotenoids with provitamin A activity (Rojas-Garbanzo et al., 2011; Matos et al., 2019).

Despite its high nutritional value, the direct consumption of peach palm fruits in Northern Brazil is traditionally made after cooking in salty water under high pressure (pressure cooker) as part of snacks at any time of day (Chisté and Fernandes, 2016; Nazário et al., 2017). The technological potential of peach palm fruits by food industries may be quite broad once their nutritional and peculiar sensory characteristics are appreciated for new products development, mainly flour production (Kaefer et al., 2013). The flour prepared from peach palm fruits was reported to show similar nutritional values to wheat flour (Santos et al., 2020), allowing its use as a promising substitute in bakery products, such as cookies, cakes, breads and others.

Nevertheless, the flour of peach palm fruits needs extensive scientific studies to expand its use since the strategy to replace wheat flour by any other flour represent a paramount approach to provide gluten-free bakery products, which may increase the life quality of people with celiac disease (Ludvigsson et al., 2014). Importantly, as a dry product, the hygroscopic behaviour of any type of flour requires much attention from its producing and storage until acquisition by final customers (Carmo and Pena, 2019). This type of investigation may be carried out by moisture sorption isotherms, which provide key information to the development and optimization of food processes through the possibility of prediction of moisture adsorption and desorption data along storage at different relative humidity conditions (Chisté et al., 2012; Carmo and Pena, 2019). There are available reports concerning the study of the technological potential of peach palm fruits to produce flour, from both their pulps (Ferreira and Pena, 2003; Pires et al., 2019) or peels (Órdóñez-Santos et al., 2016; Martínez-Girón et al., 2017). In addition, the hygroscopic behaviour of a flour prepared with oven-dried pulps of peach palm fruits was determined only by the acquisition of adsorption data at 15 °C and 35 °C (Ferreira and Pena, 2003). However, as far as our knowledge is concerned, data regarding room-temperature sorption isotherms (adsorption and desorption) of flour from peach palm fruits produced with the whole fruit were not yet reported in the literature.

Therefore, considering the limited information regarding the technological use of Amazonian peach palm fruits, the aims of our study were to demonstrate the production and applicability of two types of peach palm flour: one produced with only the cooked pulp and another with the whole cooked fruit (pulp + peel), as a strategy to the full use of these fruits. Furthermore, the hygroscopic behaviour of both types of flour was investigated at 25 °C and two types of cookies (gluten-free) were produced, followed by their characterization and sensory evaluation to verify the influence of the peel addition on cookies acceptance.

2. Material and methods

2.1. Peach palm fruits

The peach palm fruits (Bactris gasipaes Kunt) were acquired at a farmer trade fair located in Castanhal, Pará State, Brazil (1°17′49″ S and 47°55′19″ W). The access to the fruits was registered in the Brazilian National System for the Management of Genetic Heritage and Associated Traditional Knowledge (SisGen, ACC7773). The selected fruits (5 kg) were from the seedless variety, which have green-coloured peels at full ripe stage.

2.2. Production of peach palm flour

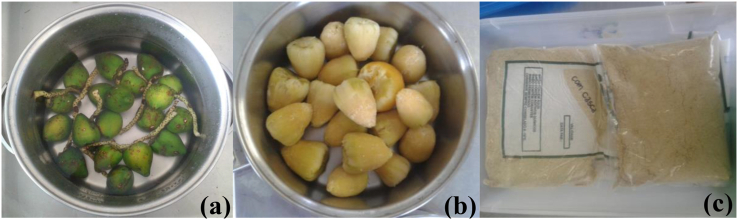

The production of peach palm flour was followed according to the process proposed by Ferreira and Pena (2003), with adaptations. The acquired fruits were selected manually based on their peel uniformity and no sign of physical damages and deterioration by fungi. The peach palm fruits were sanitized by immersion in a sodium hypochlorite solution (100 mg/L) for 15 min (Figure 1a), weighed and divided in two batches to prepare the two-different types of flour: one produced with only the pulp and the other produced with the whole fruit (pulp + peel). After that, all the fruits were cooked during 40 min under pressure (in a pressure cooker, as the Northern Brazil traditional procedure), and for the flour with only the pulp, the peels were manually separated from the pulps (Figure 1b) with a stainless-steel knife. The cooked fruits were cut in small parts, spread on aluminium trays and dried at 55 °C for 42 h in a forced-air circulation oven. The dried samples were crushed in a hammer mill, with subsequent grinding in a knife mill, and each flour was sieved (sieve number 60, with 0.250 mm opening) (Granutest, Telastem, São Paulo, SP, Brazil). Finally, both types of flour were weighed to the yield determination, vacuum-packed (Figure 1c), protected from light exposure and stored at room temperature (25 °C) until use. The yield determination (%) for each flour was calculated as the relation between the masses (g) of each flour after sieving (w2) and the fresh fruits (w1) (Eq. (1)).

| (1) |

Figure 1.

(a) Peach palm fruits from the seedless variety, which have green-coloured peels at full ripe stage, during sanitization; (b) cooked peach palm fruits without the peel; and (c) vacuum-packed peach palm flour.

2.3. Hygroscopic behaviour of peach palm flour

2.3.1. Adsorption and desorption isotherms

As dried products, such as flour, are considered stable foods due to their low water activity (Carter et al., 2015), the hygroscopic behaviour of the two types of peach palm flour was studied at 25 °C, which is their usual storage temperature. For this purpose, the moisture adsorption and desorption isotherms were obtained in a vapour sorption analyser (VSA) (Aqualab, Decagon, Puma, WA, USA) using the dynamic vapour sorption method (DVS), which consists of monitoring the moisture and water activity (aw) values of a sample exposed to environments with different relative humidity (RH) levels (Carmo and Pena, 2019). Initially, the samples of peach palm flour were subjected to complementary dehydration in a desiccator with silica gel under vacuum at room temperature for 24 h (Souza et al., 2013). Next, 1 g of each peach palm flour was weighed in a stainless-steel capsule in the microanalytical balance of the VSA. To obtain equilibrium data, the samples were submitted to different levels of RH induced by changes in the injection of dry and saturated vapour. All data were obtained in a range of aw between 0.1 and 0.9 using Δm/Δt ≥ 0.05 as convergence criterion for the equilibrium of two consecutive measurements; where Δm/Δt is the ratio between the mass variation and time variation between consecutive measurements.

2.3.2. Determination of monolayer moisture content

The monolayer moisture content (m0) for both the adsorption and desorption processes was calculated using the linear form of the BET equation (Eq. (2)) (Brunauer et al., 1938).

| (2) |

where, m = equilibrium moisture (g H2O/100 g, dry basis – d.b.); aw = water activity (dimensionless); m0 = monolayer moisture content (g H2O/100 g, d.b.) and C = constant related to the sorption heat of the first layer on primary sites.

2.3.3. Mathematical modelling of sorption isotherms

Four mathematical models were fitted to the moisture sorption data obtained for each peach palm flour at 25 °C Halsey ((Halsey, 1948)) (Eq. (3)), Oswin ((Oswin, 1946)) (Eq. (4)), Smith ((Smith, 1947)) (Eq. (5)) and GAB ((Van der Berg, 1984)) (Eq. (6)):

| (3) |

| (4) |

| (5) |

| (6) |

where, m = equilibrium moisture (g H2O/100 g, d.b.); aw = water activity (dimensionless) and a, b, m0, C, and k are models' parameters.

2.4. Preparation of peach palm cookies

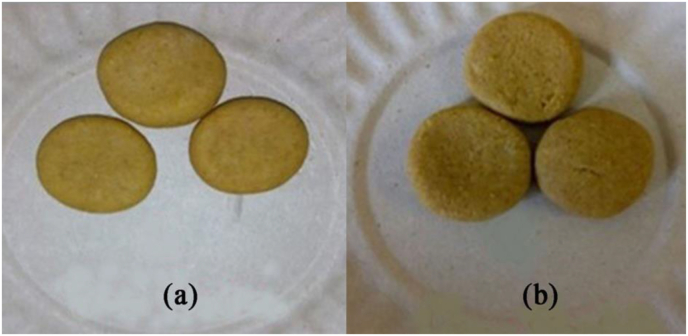

Two-formulations of cookies were prepared using both the types of peach palm flour produced in this study: one produced with flour of the pulp of peach palm and another produced with flour of the whole fruit (pulp + peel). In both cases, none percentage of wheat flour was added (gluten-free cookies), and the percentage of peach palm flour chosen for each formulation was 40%, based on preliminary tests to produce not fragile cookies (data not shown). The rest of the ingredients was the following: 24% of margarine (Bunge, São Paulo, SP, Brazil), 24% of refined sugar (Camil, São Paulo, SP, Brazil) and 12% of egg (1 unit) (Mantiqueira, Itanhandu, Minas Gerais, MG, Brazil). To prepare the cookies, margarine, egg and sugar were mixed in a stainless-steel bowl before the incorporation of the peach palm flour until reaching a homogeneous consistency, and then, the cookie doughs were left to rest at room temperature (25 °C) for 5 min. Finally, the cookie doughs were shaped into small cookies and baked into an oven at 180 °C for 20 min. For each formulation, 170 g of peach palm flour, 100 g of margarine, 100 of sugar and 50 g of egg yielded 60 units of cookies with ≈6 g each (Figure 2).

Figure 2.

Peach palm cookies produced with (a) peach palm flour prepared with only the fruit pulp and (b) peach palm flour prepared with the whole fruit (pulp + peel).

2.5. Characterization of peach palm flour and cookies

The proximate composition, physicochemical characteristics, as well as the total carotenoids and colour measurements were determined for the two types of peach palm flour and the peach palm cookies.

2.5.1. Determination of proximate composition and physicochemical properties

The analyses of moisture (105 °C) (934.06), total proteins (conversion factor of 6.25 from total nitrogen to total protein) (920.152), total lipids (945.38F), total ashes (940.26), as well as pH (direct measure) and total acidity (mEq of NaOH/100 g by titrimetry) (981.12) were determined according to Association of Official Analytical Chemists (AOAC, 2010). The total carbohydrate contents were calculated by the difference of 100% and the sum of the percentages of moisture, ashes, lipids and proteins. The total energetic values were calculated according to the general Atwater conversion factors: total energetic value (kcal/100 g) = (% protein x 4 kcal/g) + (% lipids x 9 kcal/g) + (% carbohydrates x 4 kcal/g) (FAO/WHO, 2002). The aw was determined directly in digital thermohygrometer (Decagon, Aqualab Series 4TE, Pullman, USA) at 25 °C. All the assays were carried out in triplicate and the results of the proximate composition were expressed in g/100 g (%).

2.5.2. Determination of total carotenoids

The carotenoids were exhaustively extracted from the samples (3 g) with acetone and subsequent liquid-liquid partition in petroleum ether/diethyl ether (1:1, v/v), followed by spectrophotometric readings at 450 nm (Rodriguez-Amaya, 2001). The total carotenoid contents were calculated considering the specific molar absorptivity coefficient of β-carotene in petroleum ether (2592) (Davies, 1976) and the results were expressed as mg/100 g (n = 3).

2.5.3. Colour measurements

The colour measurements were carried out by direct reading in a digital colorimeter (Konica-Minolta, CR-300, Osaka, Japan) set with diffuse illumination/0°, viewing geometry (specular component included) and D65 as the light source. The colour coordinates were obtained in the CIELAB system, where L∗ (lightness, L∗ = 0 is black and L∗ = 100 is white) and the chromatic coordinates a∗ (-a∗ = green and +a∗ = red) and b∗ (-b∗ = blue and +b∗ = yellow) were used to obtain the values of chroma (C∗ab). All the analyses were performed in triplicate.

2.6. Sensory evaluation of the peach palm cookies

The sensory evaluation of the two types of peach palm cookies was carried out with the approval of the Research Ethics Committee of the Federal University of Pará (CEP/ICS/UFPA, Belém, PA, Brazil, reference 2.492.803/CAAE 82247418.3.0000.0018) and a free and informed consent term (TCLE) was provided to all participants. Two affective tests were applied: acceptance test by a hedonic scale structured with nine points (ranging from “liked very much” – score 9 and “disliked very much” – score 1) and a purchase intention test with a seven-points structured scale (ranging from “definitely would buy” – score 7 and “definitely would not buy” – score 1) (ABNT, 2016). Seventy-three untrained participants randomly recruited among students and employees at UFPA, with ages over 18 years old, regardless their gender, and who declared themselves to be peach palm fruit and/or cookies consumers; they received coded samples of the peach palm cookies (≈6 g), at room temperature (25 °C), in an individual cabin equipped with white light (Sensory Analysis Laboratory). As both the affective tests were applied to rate the overall impression of each type of peach palm cookie, the acceptability index (AI) was calculated by Eq. (7), as suggested by Minim (2013).

| (7) |

where, Am = mean score obtained for the cookie and B = maximum score that the product may be rated (score 9 in the acceptance test and score 7 in the purchase intention test).

2.7. Statistical analysis

All the results obtained for the characterization of the two types of peach palm flour, peach palm cookies (mean ± standard deviation) and the results of the sensory analysis were assessed using Student's t-test (p ≤ 0.05) by Statistica 7.1 software.

All the models used in the mathematical modelling of sorption isotherms were fitted by the non-linear regression also using Statistica 7.1 software. The Levenberg–Marquardt method was used in the non-linear regression procedure at 95% of significance (p < 0.05). The adequacy of each mathematical model was verified by the coefficient of determination (R2), root mean square error (RMSE) (Eq. (8)) and mean relative deviation modulus (P) (Eq. (9)), which only the values lower than 10% were adopted as an indicative of a good fit for practical purposes (Peng et al., 2007).

| (8) |

| (9) |

where, mexp,i = experimental equilibrium moisture (g H2O/100 g, d.b.); mpre,i = predicted equilibrium moisture (g H2O/100 g, d.b.) and N = number of experimental determinations.

3. Results and discussion

3.1. Characterization of the produced peach palm flour

In our study, the production of peach palm flour with the whole fruit showed higher yield (32%) than the process using only the fruit pulp (22%), as expected, and these results are certainly attributed to the presence of the fruit peel. Although the peels of fruits are known to possess high nutritional potential due to the presence of vitamins, minerals, fibres and several secondary metabolites acting as bioactive compounds, they are usually only treated as agroindustrial wastes (Gowe, 2015; Sagar et al., 2018). However, each day more, several studies can be found in the literature aiming the use of fruit peels to develop new products or increase the functional properties of already existing food products (Dorta and Sogi, 2017; Li et al., 2014; Safdar et al., 2016; Sagar et al., 2018; Santos et al., 2020; Wang et al., 2013).

As can be seen in Table 1, the two types of flour produced with the selected variety of peach palm fruit presented a very similar proximate composition and physicochemical characteristics, with no statistical difference (p > 0.05) among almost all the properties. Concerning the components of the proximate composition, carbohydrates were the main class found in both the types of peach palm flour (76%), probably due to the high contents of starch reported for peach palm fruits (Leterme et al., 2005). The carbohydrate composition of 17 samples of freeze-dried pulps of Colombian peach palm fruits was investigated in details and starch was the major compound (≈72%, being 95% amylopectin and 5% amylose, on average), whereas other compounds were also reported: total sugars (2.1%), reducing sugars (1.4%), crude fibres (2%), and fibres soluble on neutral (3.9%) and acid detergents (1.8%) (Leterme et al., 2005). The contents of fibre in both the types of peach palm flour are expected to be low, since 21 different genotypes of peach palm fruits also harvested in Northern Brazil showed low total fibre contents (0.87–3.40%, dry basis) (Carvalho et al., 2013); as well as peach palm flour exhibited 5.47% of total fibre contents (5.03% insoluble +0.44% soluble) (Pires et al., 2019); and in another study, a breakfast cereal enriched with whole peach palm fruit presented 3.11% (dry basis) of total dietary fibre contents (Santos et al., 2020). Therefore, considering the high contents of starch in pulps of peach palm fruits, the two types of flour can be considered as starchy food products, and such information are useful to further investigations related to the development of new products, incorporation in existing formulations, as well as stability during storage.

Table 1.

Proximate composition, physicochemical characterization and total carotenoid contents of the peach palm flour prepared with only the fruit pulp and the peach palm flour prepared with the whole fruit (pulp + peel).

| Peach palm flour |

||

|---|---|---|

| Fruit pulp | Whole fruit (pulp + peel) | |

| Total carbohydrates (%) | 76.2 ± 0.8a | 76.1 ± 0.6a |

| Total lipids (%) | 7.8 ± 0.7a | 7.3 ± 0.6a |

| Moisture (%) | 6.94 ± 0.04b | 7.16 ± 0.05a |

| Total proteins (%) | 6.9 ± 0.1b | 7.3 ± 0.1a |

| Ashes (%) | 2.08 ± <0.01a | 2.07 ± 0.06a |

| Total energetic value (kcal/100 g) | 403 ± 2a | 400 ± 3a |

| pH | 6.08 ± 0.01a | 6.03 ± 0.01b |

| Total acidity (mEq NaOH/100 g) | 1.44 ± 0.08b | 1.7 ± 0.1a |

| aw | 0.39 ± 0.01a | 0.41 ± <0.01a |

| L∗ | 79.7 ± 0.3a | 77.1 ± 0.4b |

| a∗ | -1.98 ± 0.01b | -4.2 ± 0.1a |

| b∗ | 34.2 ± 0.3a | 34.1 ± 0.3a |

| C∗ab | 34.3 ± 0.2a | 34.5 ± 0.5a |

| Total carotenoids (mg/100 g) | 2.5 ± 0.2b | 9.7 ± 0.3a |

All the values (mean ± standard deviation, n = 3, dry basis) with the same superscript letters in the same line are not statistically different (p > 0.05) (Student test).

In relation to the other constituents, the contents of lipids found in both the types of peach palm flour were lower than the mean values reported for the 17 samples of freeze-dried pulps of Colombian peach palm fruits (11.4%) (Leterme et al., 2005); and the contents of ashes and total proteins were in the same range reported for 21 genotypes of peach palm fruits collected in Pará State (Brazil) (Carvalho et al., 2013). The low total acidity values and pH at 6.0 characterize both types of flour as low acidic products; and the aw at 0.39 and 0.41 values suggest microbiological stability (Jay, 2005). In general, the both types of peach palm flour produced in this study showed similar proximate composition with those reported for peach palm flour produced with fruits from unknown varieties (Ferreira and Pena, 2003; Kaefer et al., 2013; Pires et al., 2019), including total energetic value, which can be considered high since the Daily Reference Intake (DRI) for adults is 2,000 kcal (HHS & USDA, 2015).

The colour parameters indicated that the flour produced with the whole fruit (pulp + peel) was slightly darker (L∗ = 77.1) than the flour with only the pulp (L∗ = 79.7), probably due to the presence of the peel, which can be supported by its greener colouring (a∗ = -4.2). The production of peach palm flour with the whole fruit increased the incorporation of carotenoids with almost four times high contents than the flour made with only the fruit pulp (Table 1). According to the literature, the major carotenoids reported for the pulp of peach palm fruits (unknown variety) were β-carotene, δ-carotene and γ-carotene (De Rosso and Mercadante, 2007), which were the same found in peel of fruits of orange and yellow coloured variety (Matos et al., 2019; Chisté et al., 2021). Among these major carotenoids, β-carotene and γ-carotene are provitamin A compounds and the vitamin A values (expressed as retinol activity equivalent, RAE) attributed to the peel of peach palm fruits was 8.5 μg RAE/g (Matos et al., 2019), which was higher than the RAE reported for the pulp of peach palm fruits (7.4) and palm oil (7.6) (De Rosso and Mercadante, 2007). According to Fernández-García et al. (2012), the Institute of Medicine of the National Academy of Sciences (USA) established daily recommendation levels (DRL) of carotenoids for the population, being 900 mg/day for men and 700 mg/day for women. In this study, both the types of flour of peach palm fruits may supply about 0.3–1% (men) and 0.3–1.3% (women) of the DRL with the consumption of 100 g of flour; thus, they can be seen as a useful strategy to increase the regular intake of carotenoids by the local population.

3.2. Hygroscopic behaviour of the peach palm flour

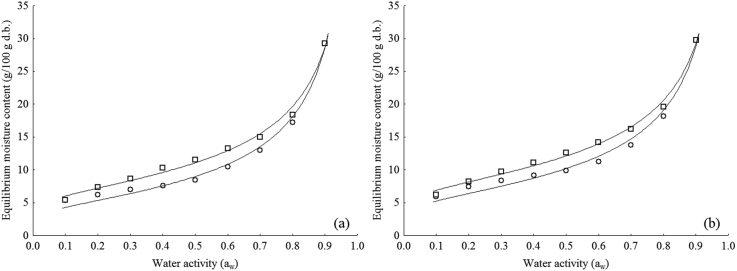

According to the adsorption and desorption isotherms (Figure 3), both types of peach palm flour adsorbed ≈29% of moisture at the highest aw (0.9) at 25 °C; and during the desorption process, the moisture content reached 5.4 and 6.2%, at the lowest aw (0.10), for the flour produced with the pulp and the whole fruit, respectively. Both sorption isotherms are classified as type-II (sigmoidal shape) (IUPAC, 1985), specifically more Langmuir-like type II isotherm, as proposed by Blahovec and Yanniotis (2009), which are typical of food with high starch contents. According to Scott (1957), the microbiological stability of a food product is expected at aw <0.6; thus, during storage conditions at 25 °C, both types of peach palm flour are expected to avoid microbial proliferation at moisture contents lower than 10.46%, d.b. (flour with the fruit pulp) and 11.25%, d.b. (flour with the whole fruit).

Figure 3.

Moisture adsorption (◯) and desorption (□) isotherms at 25 °C for the peach palm flour prepared with only the fruit pulp (a) and peach palm flour prepared with the whole fruit (pulp + peel) (b) fitted by the Halsey model (──).

Hysteresis loop between the adsorption and desorption isotherms can be observed in Figures 3a and 3b for both the types of peach palm flour, which presented the same behaviour. According to Caurie (2007), the lower the hysteresis loop, the greater the stability of the product. A linear behaviour was observed between the moisture contents and aw values until aw = 0.7, for both the types of flour. From this value, the moisture showed an exponential increase, which suggest that both products will absorb moisture at faster rate when stored at relative humidity (RH%) higher than 70%. Thus, under these conditions, these types of dried products should be preferably stored in packages with low permeability to water vapour and light, which will also avoid lipid peroxidation of peach palm flour since the lipid contents accouted for about 7% of the proximate composition (Table 1).

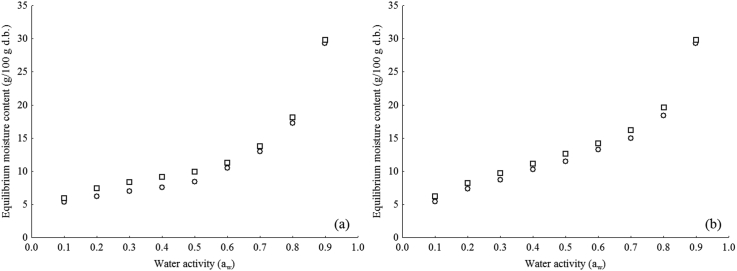

Figure 4 shows that the adsorption (Figure 4a) and desorption (Figure 4b) moisture isotherms for the peach palm flour prepared with the whole fruit exhibited equilibrium moisture values slightly higher than those observed by the respective moisture sorption isotherms for the peach palm flour prepared with only the fruit pulp, in all the range of aw. This behaviour can be attributed to the slightly higher moisture and proteins content of the former when compared to the latter (Netto et al., 1998; Hogan & O'callaghan, 2013). These results are important for practical purposes and indicate that the peach palm flour prepared with the whole fruit required greater care during packaging, storage and marketing. This behaviour corroborates with the observed to microbiological stability, as mentioned previously.

Figure 4.

Moisture adsorption (a) and desorption (b) isotherms at 25 °C for the peach palm flour prepared with only the fruit pulp (◯) and peach palm flour prepared with the whole fruit (pulp + peel) (□).

The desorption monolayer moistures (m0) were 6.54 and 6.99 g H2O/100 g, d.b. (R2 ≥ 0.99) for the flour with the pulp and the flour with the whole fruit, respectively; and these values indicate the moisture contents to be reached by both types of flour during drying process in order to avoid unnecessary energy consumption (Mishra et al., 1996). The peach palm flour prepared with the whole fruit presented higher m0 values probably due to the presence of the peel that may present more interactions among water molecules and fibre structures. According to the literature, other types of flour showed values in the same range at 25 °C, such as cassava flour of water group (7.9 H2O/100 g, d.b.) (Chisté et al., 2015), cassava flour of dry group (6.7–7.6 H2O/100 g, d.b.) (Araújo and Pena, 2020) and tapioca flour (4.9–6.7 g H2O/100 g) (Chisté et al., 2012; Carmo and Pena, 2019).

3.3. Mathematical modelling of sorption isotherms

Table 2 shows the parameters of the mathematical modelling fitted to the experimental data of moisture sorption of both types of flour. The mathematical models that presented the high capacity to predict the moisture isotherms for both adsorption and desorption were Halsey and GAB (R2 ≥ 0.99 and P<7.5%). Thus, in this study, the Halsey model was chosen to predict the moisture data of peach palm flour (Figure 3) since it is a bi-parametric model and easier to solve by linear regression. This model was also efficient to predict the hygroscopic behaviour of two types of cassava flour (Chisté et al., 2015).

Table 2.

Model and statistical parameters of mathematical modelling of moisture sorption data for the peach palm flour prepared with only the fruit pulp and the peach palm flour prepared with the whole fruit (pulp + peel).

| Parameters | Peach palm flour |

|||

|---|---|---|---|---|

| Fruit pulp |

Whole fruit (pulp + peel) |

|||

| Adsorption | Desorption | Adsorption | Desorption | |

|

Halsey | ||||

| a | 24.28 | 79.06 | 46.14 | 141.48 |

| b | 1.62 | 1.97 | 1.81 | 2.13 |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 |

| P | 7.10 | 4.68 | 7.23 | 3.77 |

| RMSE |

0.67 |

0.63 |

0.79 |

0.53 |

|

Oswin | ||||

| a | 9.24 | 11.47 | 10.54 | 12.57 |

| b | 0.50 | 0.40 | 0.44 | 0.37 |

| R2 | 0.97 | 0.98 | 0.96 | 0.98 |

| P | 13.64 | 6.66 | 13.09 | 5.47 |

| RMSE |

1.30 |

0.96 |

1.42 |

0.84 |

|

Smith | ||||

| a | 2.56 | 4.54 | 3.83 | 5.54 |

| b | 10.30 | 9.89 | 9.99 | 9.81 |

| R2 | 0.97 | 0.98 | 0.97 | 0.99 |

| P | 14.80 | 6.31 | 12.09 | 5.51 |

| RMSE |

1.70 |

1.15 |

1.62 |

0.96 |

|

GAB | ||||

| m0 | 4 | 5 | 5 | 6 |

| C | 1.8.107 | -5.6.106 | 8.4.106 | -5.3.106 |

| K | 1 | 1 | 1 | 1 |

| R2 | 0.99 | 0.99 | 0.99 | 0.99 |

| P | 4.31 | 7.43 | 6.28 | 6.43 |

| RMSE | 0.48 | 0.93 | 0.78 | 0.88 |

a, b, C and k – model parameters; m0 – monolayer moisture content (g H2O/100 g d.b.); R2 – coefficient of determination; P – relative mean deviation and RMSE – root mean square error.

3.4. Peach palm cookies and sensory evaluation

The composition of the cookies prepared with the peach palm flour (pulp fruit flour and whole fruit flour, respectively) (Figure 2) are presented in Table 3. All the properties showed statistical difference (p ≤ 0.05) for both the cookies, except for total lipids and ashes (p > 0.05). The total energetic value for both the cookies were ≈502 kcal/100 g. Regarding the total carotenoid contents, the peach palm cookies prepared with only the pulp flour and the whole fruit flour may supply, respectively, about 0.6 and 1.2% (men) and 0.8 and 1.5% (women) of the daily recommendation level of carotenoids (Fernández-García et al., 2012), with the consumption of 60 g of cookies (10 units). Thus, these food products may be indicated for further investigations for hypercaloric diets, children and adolescents in the growth phase and mainly, for the celiac public, since it has not wheat flour in its formulation.

Table 3.

Proximate composition and total carotenoid contents of the peach palm cookies prepared with only the pulp flour and the whole fruit flour.

| Cookies |

||

|---|---|---|

| Pulp flour | Whole (pulp + peel) flour | |

| Total carbohydrates (%) | 61.8 ± 0.8a | 59.1 ± 0.6b |

| Total lipids (%) | 25.0 ± 1.0a | 26.4 ± 0.5a |

| Moisture (%) | 4.9 ± 0.2b | 6.26 ± 0.07a |

| Total proteins (%) | 6.33 ± 0.07b | 7.01 ± 0.07a |

| Ashes (%) | 1.34 ± 0.04a | 1.24 ± 0.03b |

| Total energetic value (kcal/100 g) | 498.0 ± 10.6a | 502.0 ± 6.5a |

| Total carotenoids (mg/100 g) | 10.23 ± 0.41b | 18.1 ± 0.3a |

All the values (mean ± standard deviation, n = 3, dry basis) with the same superscript letters in the same line are not statistically different (p > 0.05) (Student test).

Regarding the sensory evaluation of the cookies, the acceptance means for the overall impression of the cookies prepared with the whole fruit flour, as well as its acceptability index values (AI) [6.55 (±1.75) and 72.75%, respectively], were not statistically different (p < 0.05) to that observed for the cookies prepared with the peach palm pulp flour [6.32 (±1.91) and 70.17%, respectively]. Therefore, based on these results, both formulations were considered as sensorially accepted, since AI >70% is mentioned as the minimum value to suggest sensory acceptance (Dutcosky, 2013).

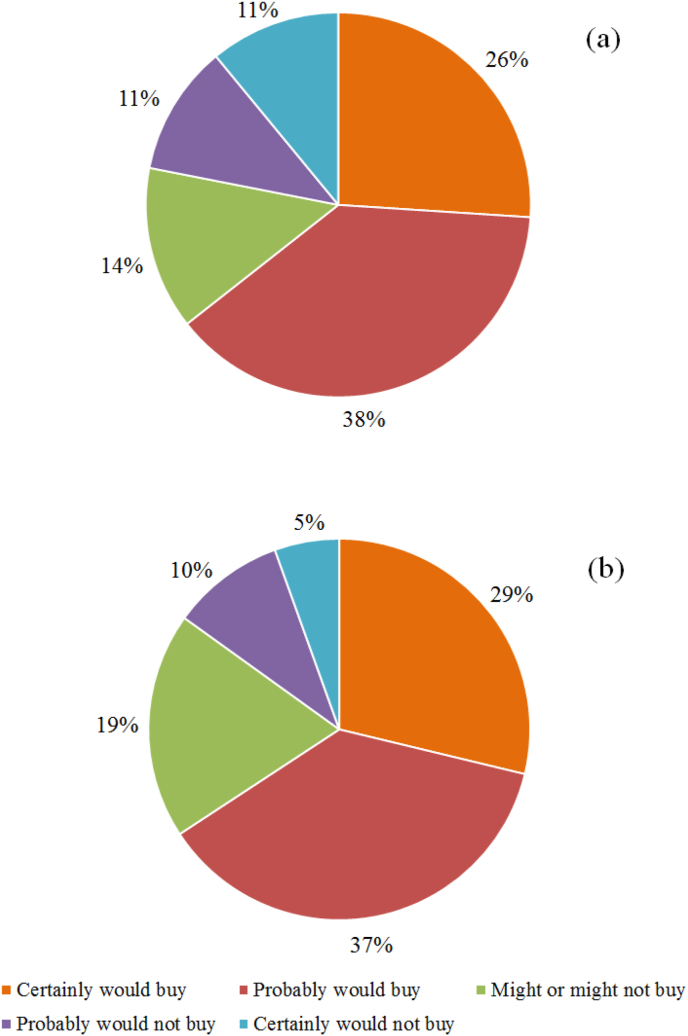

The purchase intention inquiry (sum of “certainly would buy”, “probably would buy” and “might or might not buy”) for the cookies produced with the whole fruit flour showed higher percentage (85%) than for the cookies produced with flour with only the fruit pulp (78%) (Figure 5). As peach palm fruits are highly appreciated in Northern Brazil, as mentioned before (Chisté and Fernandes, 2016; Nazário et al., 2017), these results show that peach palm flour with or without the fruit peel as ingredient to prepare cookies (or other bakery products) can be seen as an important strategy of using the fruit, expanding its consumption beyond as part of snacks.

Figure 5.

Purchase intention of the peach palm cookies produced with (a) peach palm flour prepared with only the fruit pulp and (b) peach palm flour prepared with the whole fruit (pulp + peel).

4. Conclusion

Two types of flour were obtained from peach palm fruits and used to produce cookies. This is the first time this variety of peach palm fruit was investigated to produce flour followed by the application in the development of a food product. Both types of peach palm flour showed high carbohydrates and lipids contents, and according to their hygroscopic evaluation, both products will be more susceptible to gain moisture during storage at relative humidity above 70%. Moreover, the microbiological stability of both type of flour will be ensured at moisture levels lower than 10% (wet basis). The Halsey model was efficient to predict the adsorption and desorption isotherms for both the flour. After observing all these aspects, both types of flour were used to prepare cookies with good acceptability index values and purchase intention. Thus, the use of flour of peach palm fruits as ingredient to be added in the formulation of baking products can be seen as an important alternative for valorising peach palm in the Amazonia.

Declarations

Author contribution statement

Gessica Silva Ribeiro, Mariana Karolyne Conceição Monteiro: Performed the experiments; Analyzed and interpreted the data; Wrote the paper.

Juliana Rodrigues do Carmo, Rosinelson da Silva Pena: Analyzed and interpreted the data; Wrote the paper.

Renan Campos Chisté: Conceived and designed the experiments; Analyzed and interpreted the data; Contributed reagents, materials, analysis tools or data; Wrote the paper.

Funding statement

This work was supported by Fundação Amazônia de Amparo a Estudos e Pesquisas (FAPESPA, Belém, PA, Brazil) [Process 2017/52864 – ICAAF Nº 013/2018].

Data availability statement

Data included in article/supplementary material/referenced in article.

Declaration of interests statement

The authors declare no conflicts of interest. Renan Campos Chisté is part of the Editorial Advisory Board of Heliyon journal (Food Science and Nutrition section).

Additional information

No additional information is available for this paper.

References

- Araújo A.L., Pena R.S. Effect of particle size and temperature on the hygroscopic behaviour of cassava flour from dry group and storage time estimation. CyTA - J. Food. 2020;18(1):178–186. [Google Scholar]

- Association of Official Analytical Chemists – AOAC . eighteenth ed. AOAC; Arlington: 2010. Official Methods of Analysis of Association of Official Analytical Chemists International. [Google Scholar]

- Associação Brasileira de Normas Técnicas – ABNT . 2016. NBR ISO 11136:2016: Sensory Analysis – Methodology – General Guidance for Conducting Hedonic Tests with Consumers in a Controlled Area.https://www.abntcatalogo.com.br/norma.aspx?ID362824 [Google Scholar]

- Blahovec J., Yanniotis S. Modified classification of sorption isotherms. J. Food Eng. 2009;91(1):72–77. [Google Scholar]

- Brunauer S., Emmet T.H., Teller F. Adsorption of gases in multimolecular layers. J. Am. Chem. Soc. 1938;60(2):309–319. [Google Scholar]

- Carmo J.R., Pena R.S. Influence of the temperature and granulometry on the hygroscopic behavior of tapioca flour. CyTA - J. Food. 2019;17(1):900–906. [Google Scholar]

- Carter B.P., Galloway M.T., Morris C.F., Weaver G.L., Carter A. The case for water activity as a specification for wheat tempering and flour production. Cereal Foods World. 2015;60(4):166–170. [Google Scholar]

- Carvalho A.V., Beckman J.C., Maciel R.A., Farias Neto J.T. Physical and chemical characteristics of peach palm fruits in the state of Pará. Rev. Bras. Frutic. 2013;35(3):763–768. [Google Scholar]

- Caurie M. Hysteresis phenomenon in foods. Int. J. Food Sci. Technol. 2007;42(1):45–49. [Google Scholar]

- Chisté R.C., Fernandes E. Bioactive compounds from Amazonian fruits and their antioxidant properties. In: Silva L.R., Silva B.M., editors. Natural Bioactive Compounds from Fruits and Vegetables as Health Promoters – Part I. Bentham Science Publishers; United Arab Emirates: 2016. pp. 244–264. [Google Scholar]

- Chisté R.C., Silva P., Lopes A., Pena R.S. Sorption isotherms of tapioca flour. Int. J. Food Sci. Technol. 2012;47(4):870–874. [Google Scholar]

- Chisté R.C., Cardoso J.M., Silva D.A., Pena R.S. Hygroscopic behaviour of cassava flour from dry and water groups. Ciência Rural. 2015;45(8):1515–1521. [Google Scholar]

- Chisté R.C., Costa E.L.N., Monteiro S.F., Mercadante A.Z. Carotenoid and phenolic compound profiles of cooked pulps of orange and yellow peach palm fruits (Bactris gasipaes) from the Brazilian Amazonia. J. Food Compos. Anal. 2021;99:103873. [Google Scholar]

- Davies B.H. Carotenoids. In: Goodwin T.W., editor. Chemistry and Biochemistry of Plant Pigments. Academic Press; London: 1976. pp. 38–165. [Google Scholar]

- De Rosso V.V., Mercadante A.Z. Identification and quantification of carotenoids, by HPLC-PDA-MS/MS, from Amazonian fruits. J. Agric. Food Chem. 2007;55:5062–5072. doi: 10.1021/jf0705421. [DOI] [PubMed] [Google Scholar]

- Dorta E., Sogi D.S. Value added processing and utilization of pineapple by-products. In: Lobo M.G., Paull R.E., editors. Handbook of Pineapple Technology, Production, Postharvest Science, Processing and Nutrition. John Wiley and Sons; Oxford: 2017. pp. 196–220. [Google Scholar]

- Dutcosky S.D. fourth ed. Champagnat; Curitiba: 2013. Análise sensorial de alimentos. [Google Scholar]

- Fernández-García E., Carvajal-Lérida I., Jarén-Galán M., Garrido-Fernández J., Pérez-Gálvez A., Hornero-Méndez D. Carotenoids bioavailability from foods: from plant pigments to efficient biological activities. Food Res. Int. 2012;46(2):438–450. [Google Scholar]

- Ferreira C.D., Pena R.S. Hygroscopic behavior of the pupunha flour (Bactris gasipaes) Food Sci. Technol. 2003;23(2):251–255. [Google Scholar]

- Food and Agriculture Organization of the United Nations – FAO/WHO Food energy: methods of analysis and conversion factors. Food Nutr. 2002 http://www.fao.org/uploads/media/FAO_2003_Food_Energy_02.pdf [Google Scholar]

- Gowe C. Review on potential use of fruit and vegetables by-products as a valuable source of natural food additives. Food Sci. Qual. Manag. 2015;45(1):47–61. ISSN: 2225-0557. [Google Scholar]

- Halsey G. Physical desorption on non-uniforme surfaces. J. Chem. Phys. 1948;16(10):931–937. [Google Scholar]

- Hogan S., O’callaghan D. Moisture sorption and stickiness behaviour of hydrolysed whey protein/lactose powders. Dairy Sci. Technol. 2013;93(4):505–521. [Google Scholar]

- International Union of Pure and Applies Chemistry – IUPAC Reporting physisorption data for gas⁄solid systems. Pure Appl. Chem. 1985;57(4):603–619. [Google Scholar]

- Jay M.J. sixth ed. Artmed; Porto Alegre: 2005. Microbiologia de alimentos. [Google Scholar]

- Kaefer S., Fogaça A.O., Storck C.R., Kirsten V.R. Cake with pupunha flour (Bactris gasipaes): analysis of the centesimal and sensory composition. Braz. J. Food Nutr. 2013;24(3):347–352. ISSN: 0103-4235. [Google Scholar]

- Leterme P., García M.-F., Londoño A.-M., Rojas M.-G., Buldgen A., Souffrant W.-B. Chemical composition and nutritive value of peach palm (Bactris gasipaes Kunth) in rats. J. Sci. Food Agric. 2005;85:1505–1512. [Google Scholar]

- Li X., He X., Lv Y., He Q. Extraction and functional properties of water-soluble dietary fiber from apple pomace. J. Food Process. Eng. 2014;37(3):293–308. [Google Scholar]

- Ludvigsson J.F., Bai J.C., Biagi F., Card T.R., Ciacci C., Ciclitira P.J. Diagnosis and management of adult coeliac disease: guidelines from the British Society of Gastroenterology. Gut. 2014;63(8):1210–1228. doi: 10.1136/gutjnl-2013-306578. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Martínez-Girón J., Figueroa-Molano A.M., Órdóñez-Santos L.E. Effect of the addition of peach palm (Bactris gasipaes) peel flour on the color and sensory properties of cakes. Food Sci. Technol. 2017;37(3):418–424. [Google Scholar]

- Matos K.A.N., Lima D.P., Barbosa A.P.P., Mercadante A.Z., Chisté R.C. Peels of tucumã (Astrocaryum vulgare) and peach palm (Bactris gasipaes) are by-products classified as very high carotenoid sources. Food Chem. 2019;272(30):216–221. doi: 10.1016/j.foodchem.2018.08.053. [DOI] [PubMed] [Google Scholar]

- Minim V.P.R. 3th ed. Editora UFV; Viçosa: 2013. Análise Sensorial: Estudos Com Consumidores. [Google Scholar]

- Mishra V.K., Ooraikul B., Temelli F. Physical characterization and water sorption of freeze dried dulse Palmaria palmata powder. J. Food Process. Preserv. 1996;20(1):25–39. [Google Scholar]

- Nazário P., Ferreira S.A., Borges E.E.L. Embryonic dormancy in seeds of Bactris gasipaes Kunth (peach-palm) J. Seed Sci. 2017;39(2):106–113. [Google Scholar]

- Netto F.M., Desobry S.A., Labuza T.P. Effect of water content on the glass transition, caking and stickiness of protein hydrolysates. Int. J. Food Prop. 1998;1(2):141–161. [Google Scholar]

- Órdóñez-Santos L.E., Martínez-Girón J., Figueroa-Molano A.M. Effect of the addition of peach palm (Bactris gasipaes) peel flour on the color and sensory properties of wheat bread. Braz. J. Agric. Sci. 2016;39(3):456–462. [Google Scholar]

- Oswin C.R. The kinetics of package life. III isotherm. J. Chem. Technol. Biotechnol. 1946;65(12):419–421. [Google Scholar]

- Peng G., Chen X., Wu W., Jiang X. Modeling of water sorption isotherm for corn starch. J. Food Eng. 2007;80(2):562–567. [Google Scholar]

- Pires M.B., Amante E.R., Lopes A.S., Rodrigues A.M.C., Silva L.H.M. Peach palm flour (Bactris gasipae Kunth): potential application in the food industry. Food Sci. Technol. 2019;39(3):613–619. [Google Scholar]

- Rodriguez-Amaya D.B. ILSI Press; Washington: 2001. A Guide to Carotenoid Analysis in Foods. [Google Scholar]

- Rojas-Garbanzo C., Pérez A.M., Bustos-Carmona J., Vaillant F. Identification and quantification of carotenoids by HPLC-DAD during the process of peach palm (Bactris gasipaes HBK) flour. Food Res. Int. 2011;44(7):2377–2384. [Google Scholar]

- Safdar M.N., Kausar T., Jabbar S., Mumtaz A., Ahad K., Saddozai A.A. Extraction and quantification of polyphenols from kinnow (Citrus reticulate L.) peel using ultrasound and maceration techniques. J. Food Drug Anal. 2016;25(3):488–500. doi: 10.1016/j.jfda.2016.07.010. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Sagar N.A., Sharma S.P.S., Yahia E.M., Lobo M.G. Fruit and vegetable waste: bioactive compounds, their extraction, and possible utilization. Compr. Rev. Food Sci. Food Saf. 2018;17(1):512–531. doi: 10.1111/1541-4337.12330. [DOI] [PubMed] [Google Scholar]

- Santos I.L., Schmiele M., Aguiar J.P.L., Steel C.J., Silva E.P., Souza F.C.A. Evaluation of extruded corn breakfast cereal enriched with whole peach palm (Bactris gasipaes, Kunth) Flour. Food Sci. Technol. 2020;40(2):458–464. [Google Scholar]

- Scott W.J. Water relations of food spoilage microorganisms. Adv. Food Res. 1957;7:83–127. [Google Scholar]

- Smith S.E. The Sorption of water vapour by high polymers. J. Am. Chem. Soc. 1947;69:646–651. doi: 10.1021/ja01195a054. [DOI] [PubMed] [Google Scholar]

- Souza T.C.L., Souza H.A.L., Pena R.S. A rapid method to obtaining moisture sorption isotherms of a starchy product. Starch/Stärke. 2013;65(5–6):433–436. [Google Scholar]

- United States Department of Health and Human Services & United States Department of Agriculture – HHS/USDA . eighth ed. USDA; Washington DC: 2015. Dietary Guidelines for Americans 2015 – 2020. [Google Scholar]

- Van den Berg C. Description of water activity of foods for engineering purposes by means of the GAB model of sorption. In: Mckenna B.M., editor. Engineering and Foods. Elsevier; New York: 1984. pp. 311–321. [Google Scholar]

- Wang A., Wu L., Li X. Optimization of ultrasonic-assisted preparation of dietary fiber from corn pericarp using response surface methodology. J. Sci. Food Agric. 2013;93(12):2922–2926. doi: 10.1002/jsfa.6083. [DOI] [PubMed] [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.

Data Availability Statement

Data included in article/supplementary material/referenced in article.