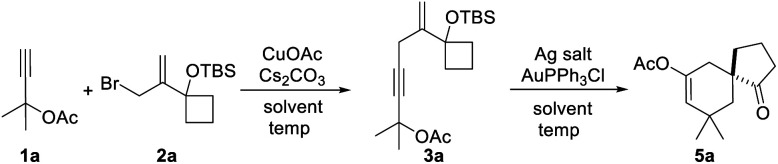

Optimization of reaction conditionsa.

| |||||

|---|---|---|---|---|---|

| Entry | Solvent | Ag salt | Temp | Product | Yield |

| 1 | DCEb | — | 70 °Cc | 3a | 82%d |

| 2 | Benzeneb | — | rtc | 3a | 40%d |

| 3 | THFb | — | rtc | 3a | 47%d |

| 4 | EtOHb | — | rtc | 3a | 55%d |

| 5 | CH3CNb | — | rtc | 3a | 55%d |

| 6 | DMFb | — | rtc | 3a | 54%d |

| 7 | DCE | AgOTf | rte | 5a | 57%f |

| 8 | DCE | AgNTf2 | rte | 5a | 66%f |

| 9 | DCE | AgSbF6 | rte | 5a | 53%f |

| 10 | DCE | AgBF4 | rte | 5a | 49%f |

| 11 | Benzeneg | AgNTf2 | rte | 5a | 11%f |

| 12 | THFg | AgNTf2 | rte | 5a | 27%f |

| 13 | EtOHg | AgNTf2 | rte | 5a | nd |

| 14 | CH3CNg | AgNTf2 | rte | 5a | 53%f |

| 15 | DMFg | AgNTf2 | rte | 5a | nd |

| 16 | DMSOg | AgNTf2 | rte | 5a | nd |

Unless specified, all reactions were carried out using 1a (0.5 mmol, 2.5 eq.), 2a (0.2 mmol, 1.0 eq.), CuOAc (30 mol%), Cs2CO3 (50 mol%), AuPPh3Cl (10 mol%), and Ag salt (10 mol%) in a reaction tube in DCE (2 mL) at indicated temperature.

The solvent of Castro–Stephens coupling for 3a.

Temperature for the first coupling reaction.

Isolated yield of 3a.

The first coupling step was carried out at 70 °C.

Isolated yield of 5a in a purification free manner.

After filtration, the filtrate was concentrated and diluted with the indicated solvent (4 mL) for the subsequent operation.