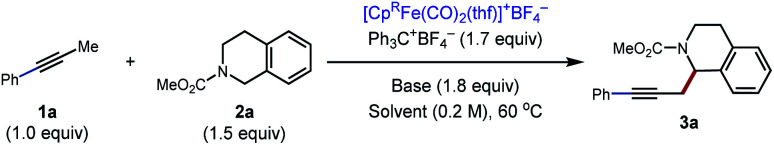

Optimization of reaction conditionsa.

| ||||

|---|---|---|---|---|

| Entry | CpR | Base | Solvent | Yieldb (%) |

| 1 | Cp* | TMPH | DCE | 31 |

| 2 | Cp* | PMP | DCE | Trace |

| 3 | Cp* | i-Pr2NEt | DCE | Trace |

| 4 | Cp* | Pyridine | DCE | 0 |

| 5 | Cp* | 2,6-Lutidine | DCE | 34 |

| 6 | Cp* | sym-Collidine | DCE | 62 |

| 7 | Cp | sym-Collidine | DCE | 10 |

| 8 | CpR1 | sym-Collidine | DCE | 14 |

| 9 | CpR2 | sym-Collidine | DCE | 20 |

| 10 | Cp* | sym-Collidine | CHCl3 | 60 |

| 11 | Cp* | sym-Collidine | PhCl | 70 |

| 12 | Cp* | sym-Collidine | PhCF3 | 83 |

| 13c | Cp* | sym-Collidine | PhCF3 | 77 (72d) |

| 14e | Cp* | sym-Collidine | PhCF3 | 56 |

All reactions were carried out with 1a (0.1 mmol), 2a (1.5 equiv.), Ph3C+BF4− (1.7 equiv.), base (1.8 equiv.) and 30 mol% of iron catalyst in solvent (0.5 mL).

NMR yield.

20 mol% of iron catalyst.

Isolated yield.

10 mol% iron catalyst. DCE = 1,2-dichloroethane. PMP = 1,2,2,6,6-pentamethylpiperidine. sym-Collidine = 2,4,6-collidine. Cp* = pentamethylcyclopentadienyl. CpR1 = 1,3-(t-Bu)2cyclopentadienyl, CpR2 = tetramethylcyclopentadienyl.