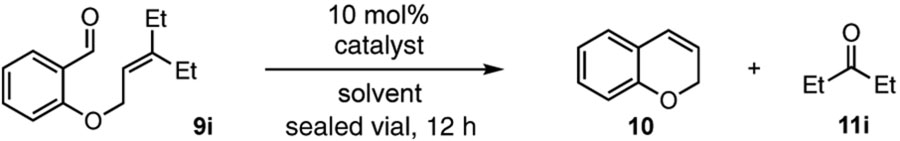

Table 2.

Optimization studies.a

| |||||

|---|---|---|---|---|---|

| entry | catalyst | solvent | temp. (°C) | conv. (%) | 3 yield (%) |

| 1 | 8• (TFA)2 | CH3CN | 140 | 65 | 48 |

| 2 | 8• (TFA)2 | DCE | 140 | 49 | 20 |

| 3 | 8• (TFA)2 | MeOH | 140 | 100 | 40 |

| 4 | 8• (TFA)2 | EtOH | 140 | 100 | 78 (73)b |

| 5 | 8• (TFA)2 | EtOH | 120 | 85 | 47 |

| 6c | TFA | EtOH | 140 | 100 | 0 |

| 7 | FeCl3 | DCE | rt | 100 | 0 |

Conditions: substrate 9i (0.2 mmol) and 10 mol % catalyst in 1.0 mL of solvent in a 5 mL sealed tube were heated to the temperature indicated for 12 h. Conversions and yields were determined by 1H NMR using CH2Br2 as an internal standard.

Isolated yield;

20 mol % TFA was used.