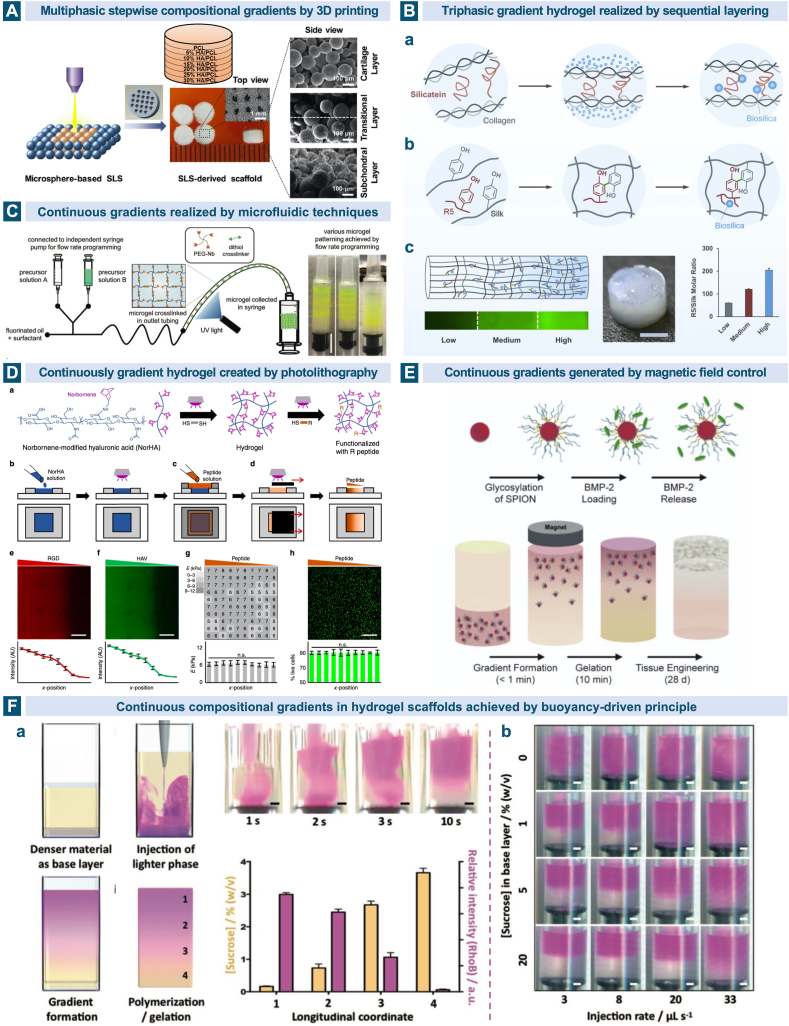

Fig. 8.

Multiphasic gradient and continuous gradient scaffolds for osteochondral tissue regeneration. A. Through selective laser sintering technique, multilayered gradient scaffold was prepared from the building blocks of PCL and HAp microspheres, with the HAp content increasing from 0 to 5%, 10%, 15%, 20%, 25% and 30% from the top to the bottom. Reproduced with permission [130]. 2017, Elsevier. B. Design strategies of the gradient composite scaffold. (a) The formation of biosilica particles on the fibrous network of collagen, also known as the in vivo silicification, is mediated by the self-assembled silicatein, (b) biosilica selective peptide R5 was utilized to mimic the natural biomineralization process and deposit biosilica particles on the silk templates, (c) the gradient composite scaffold with gradually increasing concentration of the R5 peptide from the top to the bottom. Reproduced with permission [262]. 2017, Elsevier. C. A microfludic device with a Y-shaped mixing module and a T-junction droplet generator module was used to create different patterns of microgels including the continuous physicochemical gradient one. Reproduced with permission [270]. 2019, Wiley. D. Biochemical peptide gradients in the HA based hydrogel was achieved by controlling the UV light exposure time using an opaque sliding mask [275]. E. The glycosylated superparamagnetic iron oxide nanoparticles conjugated with heparin can sequester and release growth factors and finally create a gradient biochemical pattern under an external magnetic field in the agarose hydrogel to form the gradient engineering osteochondral tissue [279]. F. The casting process of the buoyancy-driven gradient scaffold. (a) After the injection of the purple phase at a controlled rate, the system was allowed to equilibrate and form a gradient by polymerization. (b) By changing the injection rate and the sucrose concentration in the base layer, the pattern of the gradient could be easily modulated [280].