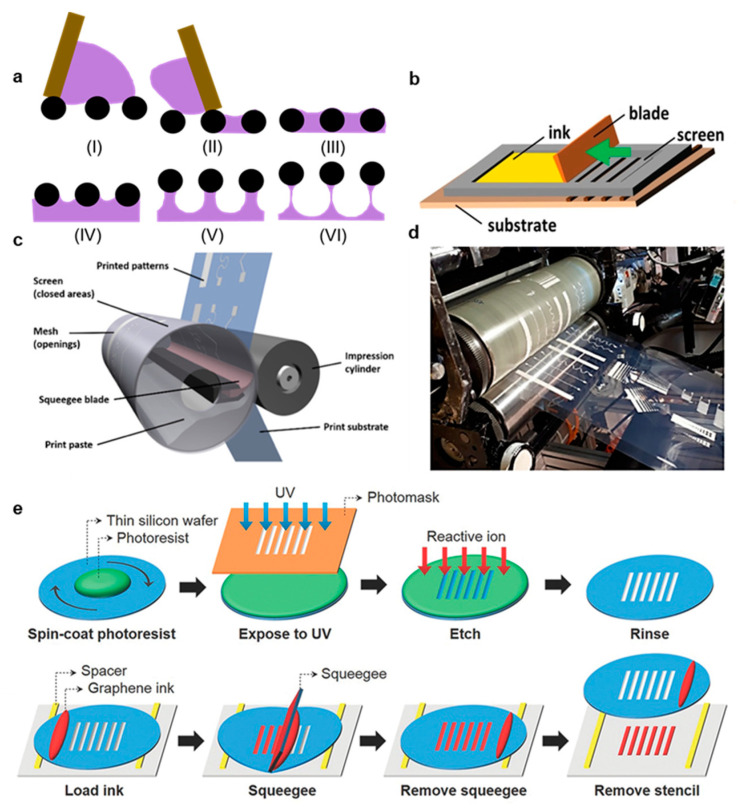

Figure 4.

High-throughput screen-printing approaches. (a) Illustration of the six stages of screen printing, as proposed by Messerschmitt et al. and investigated Abbott et al. (i) Ink flooded into the mesh. (ii) Squeegee pressure brings the mesh in contact with the substrate. (iii) Ink adheres to both the substrate and mesh. (iv–vi) As the mesh is raised off the substrate, the ink first (iv) forms a continuous structure, then (v) forms filaments, which then (vi) collapse and level to form a deposition. (reprinted with permission from ACS Omega (2021), 6, 14, 9344–9351. Copyright 2021, ACS). (b) Illustration of a sheet-to-sheet screen-printer. (reprinted with permission from Adv. Mater. (2019), 31, 1806702. Copyright 2020, Wiley). (c) Illustration of a roll-to-roll screen printer, demonstrating the key operating principles. (reprinted with permission from Ind. Eng. Chem. Res. (2019), 58, 43, 19909–19916, Copyright 2020, ACS). (d) Image of a roll-to-roll screen-printer used in nanomaterial printing. (reprinted with permission from Ind. Eng. Chem. Res. (2019), 58, 43, 19909–19916, Copyright 2020, ACS). (e) Fabrication of a thin silicon screen printing stencil for high-resolution printing and printing process implanting this stencil. (reprinted with permission from Adv. Mater. (2014), 27: 109–115. Copyright 2014, Wiley).