Table 4.

Emerging commercial Pipeline Inspection Gauge (PIG) technologies.

| PIG Type | Technical Function | Image |

|---|---|---|

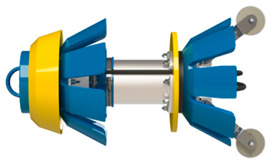

| GP | To collect information relating to the physical shape or geometry of pipelines |

ROGEO Untouched GP. Reprinted from ref. [110]. |

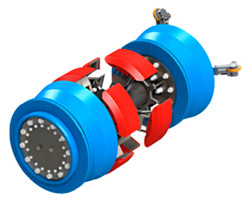

| MFL | Suitable for the pipe diameter range of 76–1422 mm and integrated for super high resolution to identify and size significant corrosion |

GE PII MagneScan SHR MFL [4] (Reproduced with permission Elsevier) |

| UT | Special configuration unites metal loss and cracks detection, available for pipeline size 20″ and above |

NDT-GLOBAL LineExplorer UCM. Reprinted from ref. [110] |

| EMAT | High reliability inspection and accurate continuous measurement of critical crack anomalies, coating disbandment |

ROSEN RoDD EMAT [119,126]. Reprinted from ref. [119] |

| EC | Integrated with deflection sensors that enable for simultaneous measurement of internal pipe profile and metal loss |

ROSEN EC [110,127]. Reprinted from ref. [110] |

| Has electromagnetic sensors embedded into the polyurethane. The array of electromagnetic sensors detects shallow internal corrosion and fatigue cracking (SICC) in dry gas or multiphase pipelines |

I2I eddy current Pioneer (Reprinted with permission from ref. [120]. Copyright 2021 I2I Pipelines.) |

|

| MWM-Array technology is used for high-resolution imaging of internal corrosion, internal initiated and relative stresses can be provided |

JENTEK ILI Tool [121] (Reproduced with permission ASME Press) |

|

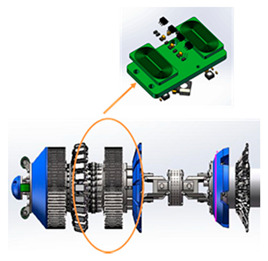

| Integrated Function | enable multiple data acquisitions for pipeline integrity with a single run, reduces inspection costs and workload |

TDW (DEF+SMFL+MFL+LFM+EMAT). Reprinted from ref. [110] |

| Specific Function | Cathode protection current measurement ILI system which can capture data that verifies the effectiveness of Cathode Protection |

Baker Hughes CPCM ™. Reprinted from ref. [110] |

| MEC | Inspection of compound pipelines with stainless steel and carbon steel in two layers |

Shenyang Academy of Instrumentation Science MEC Tool |