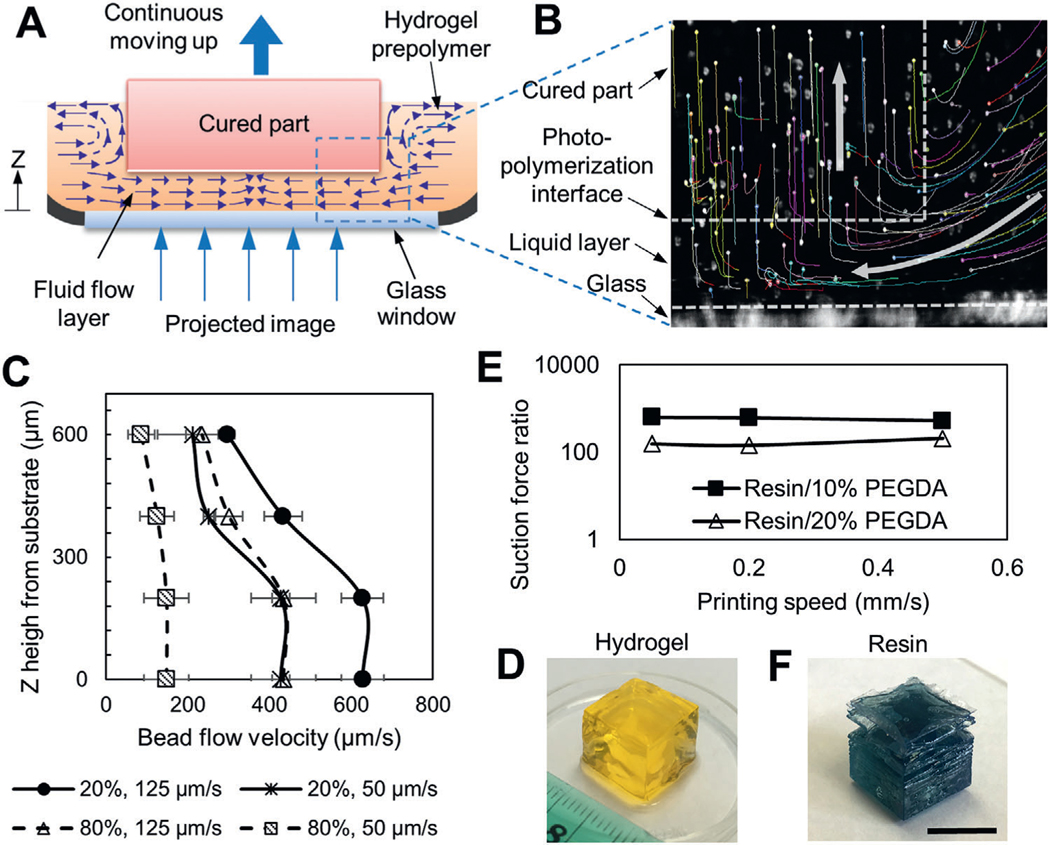

Figure 1.

FLOAT printing is enabled by high-velocity fluid flow and low fluid suction force. A) Schematic of the printing interface in FLOAT. Continuous replenishment of prepolymer solution below the curing part supports nonstop part growth. B) Tracked trajectories of fluorescence microbeads during printing. White arrows show the direction of microbead motion. Microbeads were carried by the flow into a liquid layer, trapped in the hydrogel upon photocuring and then carried upwards by the cured part. C) The flow velocity profile of 20% and 80% PEGDA prepolymer solution in uncured liquid layer under 50 and 125 μm s−1 printing speed. D) A FLOAT-printed 20% PEGDA 4 kDa hydrogel cube. E) Experimentally measured suction force ratios (WI-resin/PEGDA) at various printing speeds. F) A resin cube printed using continuous MP-SLA. Note the smooth surface and sharp edges of the hydrogel cube comparing to the rough surface and delaminated layers of the resin cube. Scale bar is 1 cm.