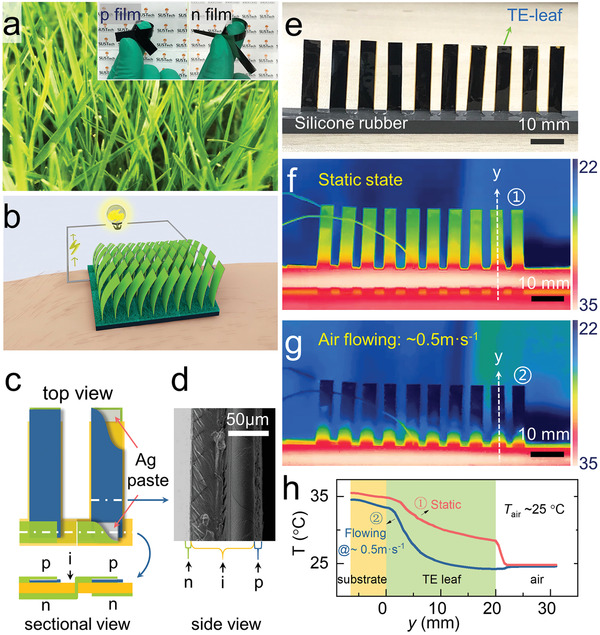

Figure 1.

Structure and the temperature distribution of leaf‐TEG. a) Grass leaves and TE flexible films. b) Concept of leaf‐TEG working under wearing condition. c) The detailed structure schematic of proposed leaf‐TEG consisting of “p” and “n” TE films separated by double‐sided‐polyimide‐tape “i”. The partial section view shows circuit connections. d) Scanning electron microscope photograph of the TE‐leaf in side view. Pores (dark areas in p‐film) in ionic liquids modified PEDOT:PSS free‐standing film improves the bending deformation ability of the film. e) Leaf‐TEG assembling with 10 back‐to‐back TE couples. f,g) Infrared photograph of leaf‐TEG under a static state and flowing air of 0.5 m s−1 at room temperature (≈25 °C) placed on a hotplate (36 °C). h) The temperature distribution of leaf‐TEG oriented the heat flow, as y‐axis shown in f) and g).