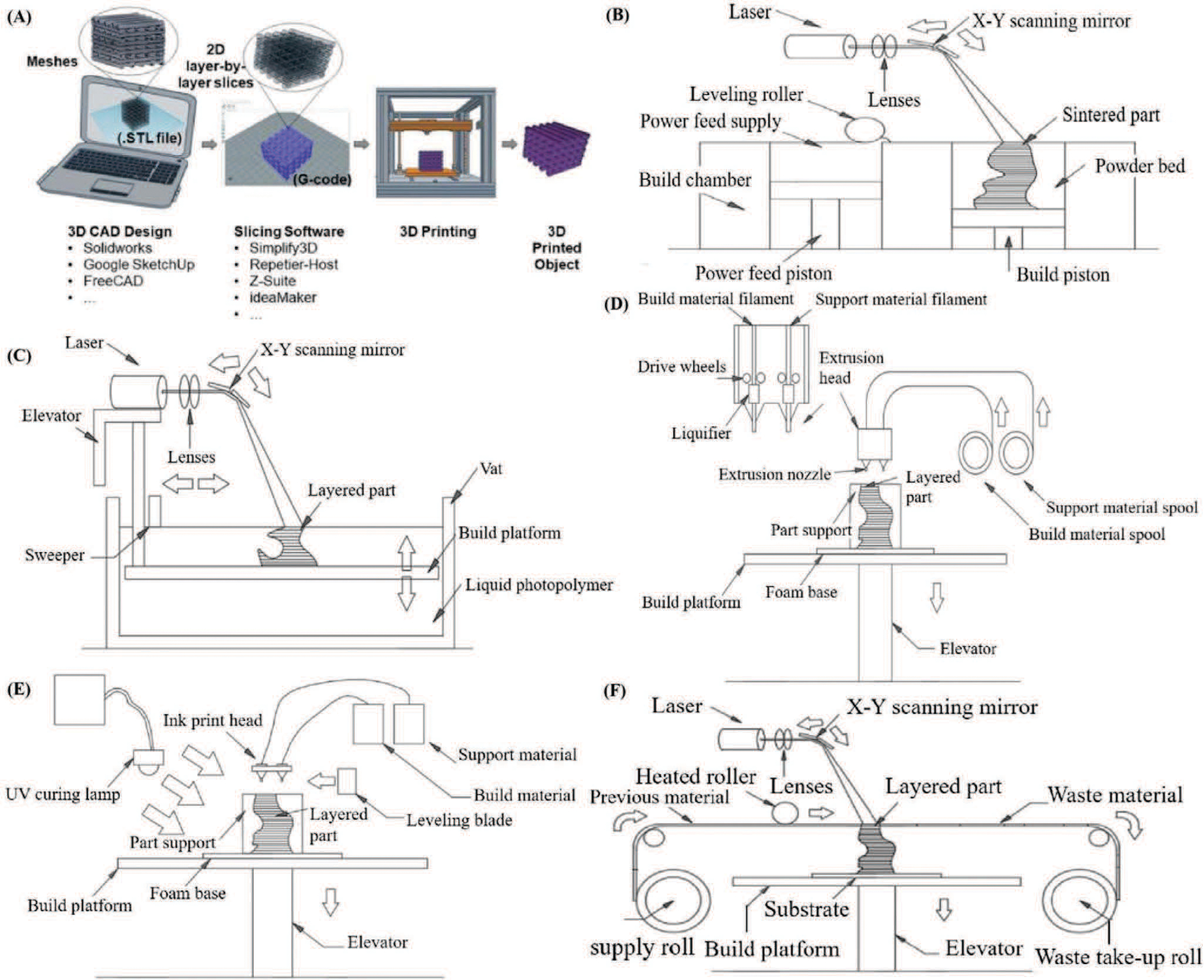

Figure 4.

Schematic illustrations of the devices being made through different types of 3D printing processes. A). Illustration of 3D (bio)printing processes from the software designs of target tissue/organs to printed models. Reproduced with permission.[150] Copyright 2019, Elsevier. B). Schematic exhibits the printing system of selective laser sintering (SLS). The focused laser beam on the top of the platform scans the powder in the chamber to define each slice of target objects. C) Schematic displays the printing system of stereolithography (SLA). The system mainly comprises of two parts—a vat that contains liquid photopolymer resin and a laser light source that facilitates the formation of desired patterns. D) Schematic illustrates the printing system of fused deposition modeling (FDM). Thermoplastic filament or metal wire is extruded from the extrusion nozzle to fabricate desired structures. E) Schematic shows the printing system of photopolymer inkjet printing (IP). The system typically employs UV light source to cure the injected ink and fabricate complex structures. F) Schematic displays the printing system of laminated object manufacturing (LOM). The system utilizes a laser to cut plastic laminates, and employs glue or chemical bonding to assemble the object.