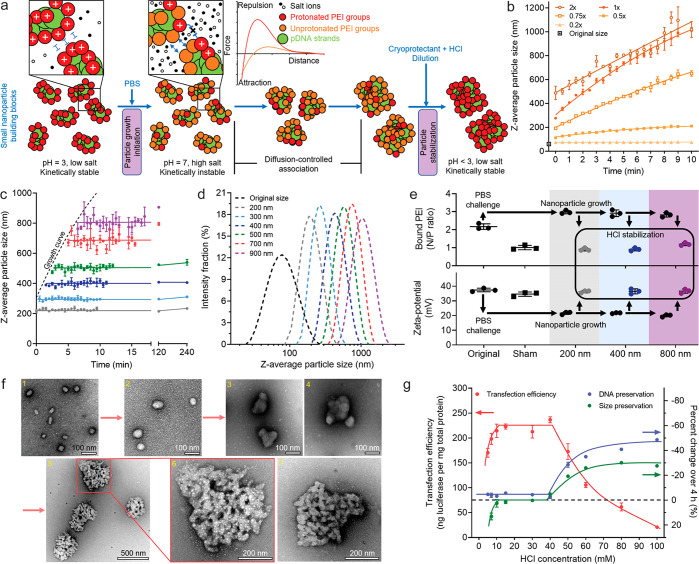

Figure 2.

Process for production of size-controlled pDNA/PEI particles in the range of 60–1000 nm through controlling the assembly kinetics and surface charge. (a) Schematic of the stepwise kinetic growth and quenching. (b) Predicable size growth induced under different concentrations of PBS. (c) The particle size growth was arrested by dilution with 20 mM HCl in 19% (w/w) trehalose solution at different time points along the growth curve in 1× PBS. (d) The z-average diameter distributions measured by DLS of a series of stabilized particles with distinct sizes. (e) The ζ potential, and bound PEI content (measured by N/P ratio) changed along with the growth and stabilization steps. The particles in the sham control were treated with premixed 1× PBS and 20 mM HCl solutions, and the size stayed unchanged (66 nm) after the treatment. (f) TEM images of the particles obtained under the conditions of (1) original 66 nm nanoparticles as the building blocks, (2) stabilized particles with an average size of 120 nm, (3, 4) stabilized particles with an average size of 180 nm, (5, 6) stabilized 400 nm particles with an enlarged view of one of the particles, and (7) another enlarged 400 nm particle with less salt precipitation (white speckles) in the negatively stained region. (g) Effect of HCl concentration used in the quenching step on size stability, DNA protection, and transfection efficiency of the 400 nm particles. Note that the percentage axis is inverted to spread data points, showing that a high HCl concentration resulted in size shrinkage and loss of pDNA. In (b) and (c) the error bars were derived from three independent experiments, demonstrating the predictability and reproducibility of the process. In (g) the error bars were derived from three replicates within a single experiment.