Abstract

The optimum formulation of a low carb pound cake was determined using alternative ingredients to replace the main sources of digestible carbohydrates in the standard formulation. Surface response methodology was a useful tool in the investigation of the use of custard apple puree (CAP), fructooligosaccharides (FOS) and soy protein hydrolysate (SPH) as partial or total replacers for wheat flour, sucrose, and powdered whole milk, respectively. The quality of pound cakes was assessed by measuring the batter and cake properties. The percentage of ingredients substitution affected the specific gravity of the batter, cakes specific volume, crumb firmness, instrumental color parameters (L*, a*, b*) and number and circularity of alveoli from pound cake slices. The model equations developed can be used for predicting the quality of the pound cake. The optimum formulation of low carb pound cake with 40.98% of CAP, 94.94% of FOS and 100% of SPH, in replacement of wheat flour, sucrose and powdered whole milk, respectively, has a 93.70% of desirability. A reduction of 60.67% in digestible carbohydrates was reached. The main reduction occurs in the starch content due to the wheat flour replacement and the non-reducing sugar content due to the sucrose partial substitution. The low carb pound cake had a moderate glycemic index (60.08%), a low glycemic load (4.69%) and accepted by the judges through sensory analysis, with an acceptability index of 72.08 ± 3.97%.

Supplementary Information

The online version contains supplementary material available at 10.1007/s13197-021-05155-9.

Keywords: Bakery products, Response surface methodology, Carbohydrates, Fibers, Glycemic index

Introduction

The interest in health and good nutrition leads to a demand for food products with reduced energy intake (Martin et al. 2007). Many diseases associated with a high intake of carbohydrates had reached an alarming proportion. Metabolic disorders related to digestible carbohydrates (mainly sugars) intake are increasing and are epidemic in industrialized countries (Carocho et al. 2017). A guideline released by the World Health Organization, in 2015, strongly recommends the reduction of the intake of free sugars to less than 10% of the total energy intake in both adults and children diets (Brouns 2015). Besides, those are consumer’s interest in buying food products with reduced free sugar content. Furthermore, starchy foods like cakes are even more problematic because starch doesn’t need a long time to be digested. Starch hydrolysis starts on the mouth and ends in the small intestine and can lead to a fast increase in blood glucose concentration up to high levels (Santos et al. 2015).

Pound cake is an appreciated baked product between consumers but with high glycemic index due to its high available carbohydrates content. Besides, the internal structure of cakes during and after baking is influenced by wheat flour and sugar levels added to the batter (Wilderjans et al. 2013). Due to the structural functionality of wheat flour and sugar in baked products, it is a difficult task to obtain good technological and sensory qualities in low digestible carbohydrate pound cake.

The search for ingredients that allow the replacement of digestible carbohydrates in cakes is the biggest challenge for the food industry. Annona squamosa, commonly known as custard apple, is a tropical fruit found around America and Asia (Orsi et al. 2012). Fruits have a high nutritional value and arouse researchers' interest in adding them to bakery products. To avoid food waste and increase the content of the dietary fiber and bioactive compounds it is beneficial to use the whole fruit, with pulp, peel, and seeds.

Fructooligosaccharide (FOS) is a functional food ingredient with a prebiotic claim often applied as a sugar replacer. FOS has been classified as soluble dietary fiber and can be used due to its nutritional advantages and technological properties, besides presenting a low sweetening power (Ishwarya and Prabhasankar 2013; Pandey et al. 2015).

Soy and its by-products, including soy protein hydrolysate (SPH), have been used in cereal-based products for increasing the protein content and for the essential amino acid balance since wheat is deficient in lysine, threonine, and tryptophan. The addition of soy products in cakes results in good physicochemical and technological properties, such as low specific gravity to the batter and high specific volume, anti-staling behavior and high crumb softness to cakes. These characteristics are achieved because soy protein hydrolysate acts like a surfactant (emulsifier and foaming agent) (Lambrecht et al. 2018). Lactose (milk sugar) is a natural nutritive sweetener that provides energy to the body in the form of carbohydrates. In bakery goods, milk promotes the lowering staling rate on the crumb. The extend of technological properties during shelf-life promoted by milk is expected from soy protein hydrolysate (Dhen et al. 2016).

This study aimed to evaluate and optimize the formulation of a pound cake using alternative ingredients to replace the main sources of digestible carbohydrates. To this purpose, the goal was to investigate if the use of custard apple puree (CAP), FOS and SPH as replacers for wheat flour, sucrose, and milk, respectively, has significant effects on the quality of low-carbohydrate pound cakes by measuring the batter and cake properties.

Materials and methods

The cakes formulation contained commercial wheat flour, hydrogenated vegetable fat, whole egg, powdered whole milk, filtered water, baking powder (containing sodium bicarbonate, monocalcium phosphate and calcium carbonate), hydroxypropyl methylcellulose (HPMC), emulsifiers (distilled monoglycerides, potassium stearate, sorbitan monostearate and polyoxyethylene sorbitan monostearate), CAP, FOS (Short-chain 114 Fructooligosaccharides P-95) and SPH (“Immunoprotein”).

Custard apple puree characterization

Custard apple was acquired from the market (city of Montes Claros) from the northern region of the State of Minas Gerais, Brazil. The fruits were selected, washed in running potable water, sanitized in a solution of sodium hypochlorite (100 ppm) for 15 min and rinsed. Subsequently, the whole fruit (peel, pulp and seeds) was disintegrated in puree with a mixer (model SMC10 Cuisine, Electrolux®) and was stored in low-density polyethylene bags at − 18 °C until analysis and use.

The CAP was analyzed regarding the moisture, protein, lipid, ash, digestible carbohydrates (sugars) and dietary fiber contents following the Association of Official Analytical Chemists methods: 934.01, 920.152, 920.39, 942.05, 982.14 and 978.10, respectively (AOAC 2019). The analysis was performed in triplicate.

Batter and pound cake preparation

The standard pound cake was prepared according to the formulation proposed by Bennion and Bamford (1997). A fat content of 40% was adopted for the standard formulation to calculate the balance of the other ingredients as described by Bennion and Bamford (1997). The standard cake formulation consisted of wheat flour (100 g), hydrogenated vegetable fat (40 g), whole egg (50 g), sucrose (58.75 g), powdered whole milk (5.85 g), filtrate water (40 g), baking powder (2.5 g), HPMC (1 g) and emulsifier (0.5 g). The amounts of CAP, FOS and SPH were established according to a 23 Central Composite Design with 3 central points and a total of 17 trials (Table S1). A second-order polynomial regression model was established to fit the experimental data for each response variable, as shown in Eq. 1.

| 1 |

where Y is the dependent variable, β0, βi, βii e βij is the constant, linear, quadratic and interaction regression terms, respectively; xi and xj are the coded values for the independent variables and; ε is the error.

The amount of CAP added ranged from 0 to 64.48% of wheat flour replacement, the amount of FOS ranged from 0 to 100% of sucrose replacement and the amount of SPH ranged from 0 to 100% of powdered whole milk replacement. The replacement of wheat flour by CAP was performed on a dry basis and the water content of the puree was subtracted from the amount of filtrated water needed in each trial.

For batter preparation, a cream was initially made by mixing hydrogenated vegetable fat, sucrose, FOS and emulsifier for 3 min at high speed in a planetary mixer (Orbit Kitchen 600, Cadence®). Then the whole eggs were added to the cream and mixed for 2 min at high speed. The remaining ingredients were incorporated into the cream at low speed. The batter (portions of 250 ± 5 g) was transferred to aluminum pans, previously greased, and baked in an electric oven (model Jady EC, Layr®) at 180 ± 5 °C until the cakes were full baked (defined by visual observation). Cake samples were cooled at room temperature for 2 h and stored in low-density polyethylene bags until evaluation, after 24 h.

Technological characteristics of batter

The specific gravity of the batter was measured according to the American Association of Cereal Chemists International through the method 55–50.01 (AACCI 2010). The analyses were performed in triplicate.

Technological characteristics of the pound cakes

The specific volume was measured using the millet seed displacement methodology according to the method 10–05.01. Cake symmetry index was calculated according to the method 10–91.01 (AACCI 2010). Pound cake’s water activity (aw) was measured directly in a water activity meter (model 4TE, Aqualab®), at room temperature (25 °C) (Felisberto et al. 2015). These analyses were performed in triplicate.

Crumb firmness was evaluated by method 74–09.01 (AACCI 2010), using a Texture Analyser (model TA.XT Plus, Stable Micro Systems®) with 50 kg cell capacity, P/36 R cylindrical probe and platform heavy-duty (HDP/90), with the following parameters of test: pre-test speed of 1.0 mm/s, test speed of 1.0 mm/s, post-test speed of 10.0 mm/s, compression of 40% and force threshold of 0.049 N. Two slice with 12.5 mm-thick from cakes were used for the test which was performed with eight repetitions for each trial.

The crumb color of the slices was evaluated, in triplicate, by CIE-L*a*b* (Commission Internationale L’Eclairage) method, using a spectrophotometer (model CM-5, Konica Minolta®). The test conditions were as follows: illuminant D65, the visual angle of 10° and calibration with reflectance specular excluded. The total color difference (ΔE) was calculated as shown by Felisberto et al. (2015).

Image analysis

The cake image analysis was evaluated by the Image J software, as described by Tasiguano et al. (2019). The number, average size (mm2) and circularity of the alveoli was measured in triplicate.

Proximate composition, total calorie value and in vitro glycemic index

The standard sample and optimized point (low-carb pound cake) were evaluated regarding the proximate composition through the evaluation of moisture, protein, lipid and ash contents following the methods 44–15.02, 46–13.01, 30–25.01 and 08–01.01 (AACCI 2010). The reducing and non-reducing sugars were analyzed according to method 982.14 (AOAC 2019) and starch content was determined by method ISI 27-1e (ISI 1999). The total dietary fiber content was calculated by difference. The total calorie value was calculated considering the converting method of Atwater (Merril and Watt 1973). The in vitro glycemic index was defined by measuring the rate of in vitro starch hydrolysis according to Goñi et al. (1997). The glycemic load was calculated according to the method proposed by Capriles et al. (2009).

Sensory analysis

The affective method was applied to sensory analysis which was approved by the Ethical Committee under the CAAE 88198918.4.0000.5108 number. The standard sample and optimal point (low-carb) were evaluated by 104 untrained judges. One slice (12.5 mm thick) from the standard pound cake and another from the low-carb one were served to the judges on monadic presentation, in random order. For each judge, the samples were served on a disposable plastic plate accompanied with filtered drinkable water at room temperature to rinse the palate between the samples. A 9-point hedonic scale (1 = dislike extremely to 9 = like extremely) was given to evaluate the sample appearance, color, aroma, taste, texture and overall impression. The acceptability index (AI) was calculated according to the equation AI = B*100/C, where B is the average grade granted to the sample and C is the maximum grade granted to the sample (Kemp et al. 2018). Both samples were also evaluated regarding their sweetness level. For this test, it was given a 9-point ideal scale (− 4 = extremely less sweet than ideal, − 3 = very much less sweet than ideal, − 2 = moderately less sweet than ideal, − 1 = slightly less sweet than ideal, 0 = ideal sweetness, 1 = slightly more sweet than ideal, 2 = moderately more sweet than ideal, 3 = very much more sweet than ideal, 4 = extremely more sweet than ideal). For purchase intention, a 5-point hedonic scale was used (1 = “I would certainly not buy it” to 5 = “I would certainly buy it”).

Statistical analysis

The technological characteristics of the batter and cakes were evaluated by the Response Surface Methodology to calculate the regression coefficient and analysis of variance (P < 0.10), with a minimum coefficient (R2) of 0.85, to ensure the validity of the predictions provided by the mathematical model and for the development of the contour plots. The desirability analysis was carried out according to Derringer and Suich (1980). The results of chemical composition, total calorie value, in vitro glycemic index and sensory analysis were evaluated by the t-Student test (P < 0.05).

Results and discussion

Custard apple puree chemical composition

CAP chemical composition was: moisture 63.04 ± 0.20 g/100 g, protein 1.24 ± 0.22 g/100 g, lipids 0.24 ± 0.05 g/100 g, ashes 1.06 ± 0.05 g/100 g, digestible carbohydrates 9.66 ± 0.93 g/100 g and total dietary fiber 26.00 ± 0.98 g/100 g.

According to the manufacturer, the content of the carbohydrate of the wheat flour was 70%, which consists mainly of starch. When compared to wheat flour, CAP had a lower content of digestible carbohydrates (9.66 g/100 g) and the amount of starch in the fruit was negligible. Wheat flour has an important function on cake batter mixing and cake baking mainly due to starch content. The replacement of wheat flour by the fruit may produce cakes with structural faults, once starch is a major determinant of the quality of wheat-based products (Wilderjans et al. 2013). On the other hand, the fiber fraction of custard apple can absorb a high amount of water (4 to 5 times in weight) (Souza et al. 2018a). This behavior can improve the batter viscosity and result in CO2 retention which is released by the chemical reaction from leavening agents during cake baking.

Technological characteristics of batter and pound cakes

Table 1 shows the experimental results for the batter and cakes characteristics. Regarding the statistically significant dependent variables (P < 0.10), the mathematical models are presented in Table 2 and the contour plots are shown in Figs. 1 and 2.

Table 1.

Experimental results of pond cakes regarding to the dependent variables

| Trials | Specific gravity (g cm−3)♠ |

Specific volume (cm3 g−1)♠ |

Symmetry index♠ |

Water activity♠ |

Firmness (N)♣ |

L*♠ |

|---|---|---|---|---|---|---|

| 1 | 0.86 ± 0.01 | 2.57 ± 0.18 | 1.92 ± 2.15 | 0.876 ± 0.001 | 9.48 ± 0.86 | 66.24 ± 0.51 |

| 2 | 0.83 ± 0.02 | 2.24 ± 0.11 | 2.89 ± 1.22 | 0.882 ± 0.001 | 8.25 ± 0.83 | 58.56 ± 0.48 |

| 3 | 0.82 ± 0.01 | 2.55 ± 0.01 | 0.95 ± 1.45 | 0.876 ± 0.002 | 8.17 ± 0.82 | 63.06 ± 0.96 |

| 4 | 0.79 ± 0.02 | 2.40 ± 0.10 | 1.89 ± 0.64 | 0.885 ± 0.003 | 7.49 ± 0.79 | 57.05 ± 0.98 |

| 5 | 0.81 ± 0.02 | 1.73 ± 0.06 | 1.43 ± 1.30 | 0.893 ± 0.001 | 8.88 ± 0.82 | 62.29 ± 0.29 |

| 6 | 0.82 ± 0.01 | 1.75 ± 0.03 | 1.34 ± 1.04 | 0.896 ± 0.001 | 7.66 ± 0.81 | 55.54 ± 0.95 |

| 7 | 0.86 ± 0.01 | 2.76 ± 0.06 | 1.99 ± 1.01 | 0.886 ± 0.001 | 7.68 ± 0.82 | 62.95 ± 0.46 |

| 8 | 0.81 ± 0.01 | 2.22 ± 0.10 | 0.99 ± 1.00 | 0.906 ± 0.005 | 7.26 ± 0.77 | 57.64 ± 1.57 |

| 9 | 0.82 ± 0.01 | 2.16 ± 0.11 | 0.55 ± 1.20 | 0.861 ± 0.001 | 11.10 ± 0.84 | 71.91 ± 1.40 |

| 10 | 0.77 ± 0.01 | 2.16 ± 0.12 | 0.46 ± 0.64 | 0.879 ± 0.003 | 7.96 ± 0.79 | 53.50 ± 1.61 |

| 11 | 0.84 ± 0.01 | 2.15 ± 0.26 | 1.10 ± 1.13 | 0.884 ± 0.001 | 8.80 ± 0.84 | 60.84 ± 0.74 |

| 12 | 0.79 ± 0.02 | 2.69 ± 0.26 | 0.63 ± 0.87 | 0.883 ± 0.003 | 5.70 ± 0.77 | 61.73 ± 0.53 |

| 13 | 0.84 ± 0.01 | 2.87 ± 0.18 | 2.95 ± 1.68 | 0.880 ± 0.001 | 7.58 ± 0.82 | 59.44 ± 0.33 |

| 14 | 0.77 ± 0.01 | 2.19 ± 0.10 | 0.57 ± 0.45 | 0.888 ± 0.005 | 5.73 ± 0.81 | 60.32 ± 0.61 |

| 15 | 0.82 ± 0.01 | 1.99 ± 0.15 | 1.80 ± 1.51 | 0.877 ± 0.002 | 8.19 ± 0.84 | 60.35 ± 1.07 |

| 16 | 0.81 ± 0.02 | 1.96 ± 0.01 | 1.43 ± 1.01 | 0.887 ± 0.002 | 7.48 ± 0.86 | 60.36 ± 1.06 |

| 17 | 0.84 ± 0.01 | 2.12 ± 0.08 | 1.22 ± 1.15 | 0.885 ± 0.004 | 6.87 ± 0.84 | 60.10 ± 2.34 |

| Standard | 0.81 ± 0.02 | 2.63 ± 0.02 | 1.59 ± 0.66 | 0.873 ± 0.003 | 6.69 ± 0.81 | 75.17 ± 0.16 |

| R2 (%) | 88.78 | 90.68 | 72.72 | 74.96 | 87.82 | 91.23 |

| Trial | a*♠ | b*♠ | Color difference♥ |

Number of alveoli♠ |

Average size (mm2)♠ |

Circularity of alveoli♠ |

|---|---|---|---|---|---|---|

| 1 | 4.98 ± 0.34 | 23.95 ± 0.57 | 14.42 ± 0.40 | 100.67 ± 9.07 | 38.88 ± 5.05 | 0.790 ± 0.019 |

| 2 | 7.36 ± 0.10 | 24.00 ± 0.29 | 18.18 ± 0.79 | 114.67 ± 14.29 | 30.82 ± 8.77 | 0.781 ± 0.006 |

| 3 | 5.75 ± 0.47 | 27.78 ± 0.23 | 13.20 ± 0.36 | 105.33 ± 20.21 | 34.21 ± 1.26 | 0.790 ± 0.012 |

| 4 | 7.40 ± 0.29 | 24.26 ± 0.30 | 18.99 ± 1.32 | 133.67 ± 10.41 | 23.13 ± 1.30 | 0.794 ± 0.034 |

| 5 | 6.57 ± 0.17 | 27.74 ± 1.00 | 12.41 ± 0.47 | 126.00 ± 15.72 | 25.82 ± 6.31 | 0.781 ± 0.041 |

| 6 | 8.28 ± 0.26 | 25.78 ± 0.50 | 15.49 ± 1.01 | 119.00 ± 8.66 | 29.73 ± 3.29 | 0.773 ± 0.033 |

| 7 | 6.27 ± 0.26 | 26.36 ± 1.00 | 13.79 ± 0.49 | 108.33 ± 20.26 | 37.05 ± 1.83 | 0.761 ± 0.022 |

| 8 | 8.28 ± 0.33 | 25.23 ± 0.49 | 17.18 ± 1.84 | 134.67 ± 10.41 | 20.23 ± 0.83 | 0.785 ± 0.019 |

| 9 | 4.54 ± 0.09 | 29.27 ± 0.64 | 9.90 ± 0.52 | 110.33 ± 11.02 | 34.21 ± 5.22 | 0.762 ± 0.022 |

| 10 | 8.67 ± 0.45 | 24.84 ± 0.50 | 24.69 ± 1.15 | 117.33 ± 7.77 | 24.50 ± 3.60 | 0.795 ± 0.033 |

| 11 | 6.91 ± 0.19 | 25.07 ± 0.35 | 11.91 ± 0.45 | 110.33 ± 7.77 | 33.10 ± 3.60 | 0.765 ± 0.033 |

| 12 | 6.67 ± 0.32 | 24.70 ± 0.14 | 16.93 ± 0.99 | 102.67 ± 5.51 | 32.74 ± 3.47 | 0.790 ± 0.026 |

| 13 | 7.23 ± 0.21 | 25.26 ± 0.54 | 15.27 ± 0.77 | 131.67 ± 13.05 | 24.00 ± 5.52 | 0.790 ± 0.029 |

| 14 | 7.23 ± 0.20 | 25.72 ± 0.53 | 15.52 ± 1.23 | 110.00 ± 14.73 | 33.92 ± 1.95 | 0.781 ± 0.040 |

| 15 | 6.80 ± 0.39 | 24.45 ± 0.29 | 16.18 ± 0.84 | 107.00 ± 9.64 | 34.66 ± 4.83 | 0.787 ± 0.022 |

| 16 | 6.75 ± 0.36 | 24.64 ± 0.60 | 16.41 ± 0.70 | 106.67 ± 0.58 | 24.43 ± 5.40 | 0.782 ± 0.013 |

| 17 | 6.68 ± 0.55 | 24.66 ± 0.10 | 19.46 ± 1.05 | 100.67 ± 9.07 | 38.88 ± 5.05 | 0.790 ± 0.019 |

| Standard | 2.04 ± 0.08 | 28.65 ± 0.95 | – | 107.67 ± 2.08 | 42.51 ± 6.75 | 0.797 ± 0.015 |

| R2 (%) | 93.45 | 86.36 | 80.95 | 94.12 | 80.42 | 96.63 |

♠Means of 3 replicates ± standard deviation; ♣Means of 8 replicates ± standard deviation; ♥Means of 3 replicates ± standard deviation calculated by error propagation

Table 2.

Mathematical models for dependent variables with significant parameters from the Central Composite Rotational Design with 3 independent variables: custard apple puree, fructooligosaccharides (FOS) and soy protein hydrolysate (SPH), desirability analysis and experimental validation

| Variables | Mathematical model | Goal | Importance | Predicted values | Experimental values | Relative deviation (%) |

|---|---|---|---|---|---|---|

| Custard apple puree | Maximize | 5 | 0.45 | |||

| Fructooligosaccharides | Maximize | 5 | 1.50 | |||

| Soy protein hydrolysate | Maximize | 5 | 1.68 | |||

|

Specific gravity (g cm−3) |

0.848−0.016x1−0.016x2−0.006x3−0.009x12−0.013x22−0.009x32 | Minimize | 5 | 0.750 | 0.727 ± 0.018 | − 3.20 |

|

Specific volume (cm3 g−1) |

2.06−0.07x1 + 0.21x2−0.18x3 + 0.09x22 + 0.16x32 + 0.18x2x3 | Maximize | 5 | 3.15 | 3.42 ± 0.04 | 2.82 |

| Firmness (N) | 7.44−0.66x1−0.56x2−0.45x3 + 0.84x12−0.35x32 + 0.23x2x3 | Minimize | 5 | 5.31 | 5.81 ± 0.04 | 8.63 |

| L* | 60.33−4.15x1−0.37x3 + 0.65x12 + 0.15x22−0.35x32 + 0.39x1x2 + 0.20x1x3 + 0.93x2x3 | In range | 3 | 60.08 | 56.92 ± 1.14 | − 5.50 |

| a* | 6.76 + 1.08x1 + 0.29x3−0.06x12 + 0.16x32−0.05x1x2−0.14x2x3 | In range | 3 | 7.79 | 8.31 ± 0.45 | 6.30 |

| b* | 24.66−1.03x1 + 0.11x2 + 0.43x3 + 0.80x12 + 0.25x32−0.34x1x2−0.75x2x3 | In range | 3 | 23.83 | 24.37 ± 1.74 | 2.21 |

| Number of alveoli | 109.76−5.54x1−2.38x2 + 7.87x3 + 3.89x12 + 2.00x32−5.50x2x3 | In range | 3 | 109.49 | 99.95 ± 2.81 | − 9.55 |

| Circularity of alveoli | 0.782−0.006x1−0.009x2−0.002x3−0.003x12 + 0.003x32 | In range | 3 | 0.770 | 0.818 ± 0.006 | 5.83 |

Independent variables x1, x2 and x3 are predicted by coded values of custard apple puree, FOS and SPH, respectively. R2 = coefficient of determination

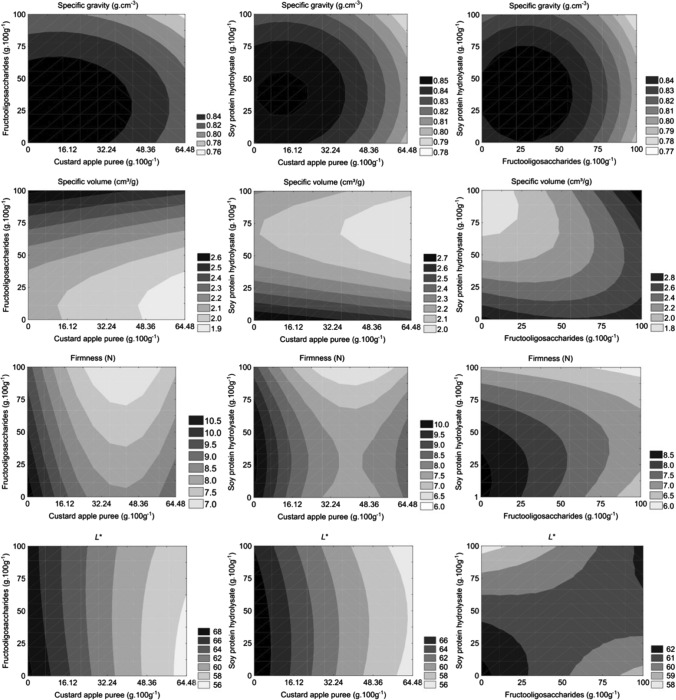

Fig. 1.

Contour plot profiles for specific gravity of batter and specific volume, firmness and parameter L* for instrumental color of pound cakes

Fig. 2.

Contour plot profiles for parameters a* and b* for instrumental color and for number and circularity alveoli of pound cakes

The specific gravity is associated with the aeration level of the batter. Lower specific gravity values indicate a higher capability of the batter to incorporate air bubbles during the ingredient mixing at the cream stage and batter capability of retaining them at the end of the mixing procedure. The specific gravity were between 0.77 and 0.86 g cm−3 for the trials and 0.81 g cm−3 for standard sample (Table 1). The greatest influence was observed with the use of CAP and FOS (β1 and β2 = 0.016, for both coefficients). A lower specific gravity (P < 0.001) was reached with higher levels of CAP, FOS and SPH, as shown on the contour plots (Fig. 1).

The results showed that an increase in the independent variables has a positive effect on air incorporation during batter whipping. The use of the whole parts of custard apple (including the pulp, peel and seeds) on the formulations increased the dietary fiber content of the batters and its probably justify the decrease of the specific gravity due to the higher viscosity provided because of the water absorption (Mau et al. 2017; Souza et al. 2018a). FOS has a similar function than sucrose and can promote a plastic behavior to the cream when mixed with fat, emulsifier and eggs. According to their technological characteristics, FOS is may be used as ingredients in cereal-based products, including cakes, because the higher molecular weight than sucrose provides an increase in cream viscosity, which is beneficial for batter aeration (Bornet 2008). Besides, SPH has an emulsifier and aeration capabilities (surfactant property) and probably justified the greater amount of air bubbles in the batter. During mechanical stirring in the cream phase occurs the exposure of hydrophobic amino acids, facilitating air trapping as a function of the mechanical energy applied. Similar results have been reported on the technological quality of cakes made of other cake ingridients and soy proteins (Majzoobi et al. 2014). On a study of gluten-free cakes, the increase in protein content was related to greater batter aeration, resulting in a lower specific gravity (Sahagún et al. 2018).

The specific volume of the cakes ranged from 1.73 to 2.76 cm3 g−1 and the standard sample showed 2.63 cm3 g−1 (Table 1) and was significantly (P < 0.001) influenced by the independent variables. According to the contour plots (Fig. 1), it was possible to observe that with a lower amount of CAP added and higher contents of FOS and SPH, the specific volume presented greater values. The use of FOS (β2 = 0.21), SPH (β3 = 0.18) and the interaction between them (β23 = 0.18) were the independent factors that caused the best response for a specific volume. It was previously reported that the use of FOS in bread was effective in retarding the starch gelatinization and protein denaturation and result in increased bread loaf volume (Schmiele et al. 2017). The use of FOS in cakes is also beneficial once the increasing the batter viscosity and, with the synergic effect of the surfactant capability of SPH, resulted in a greater expansion of gas bubbles during baking and an increase in the specific volume of the product. So, the FOS and SPH circumvent the quality loss promoted by the CAP addition. The behavior of specific volume is in agreement with the specific gravity, where both dependent variables are indirectly proportional.

Regarding cake appearance after the baking process, the symmetry index was assessed. This characteristic can indicate differences in the formation and stability of cake structure (De la Hera et al. 2012). Pound cakes need a higher value for the symmetry index because the thickness of the cake in the middle part should be greater to the sides, thus presenting a slightly concave surface feature. The addition of CAP, FOS and SPH had no significant effect (R2 = 0.7272) on the symmetry index, which ranged from 0.46 to 2.95 for the trials and presented 1.59 for the standard sample (Table 1).

In the development of new products by changing ingredients in cakes, the availability of water to occur starch gelatinization and protein denaturation is extremely important. Besides, the chemical interaction of water with ingredients can modify the water activity and result in a change in shelf life, stability and safety of the cakes. An increase in water activity in cakes is not desirable when substituting one ingredient for another (Wilderjans et al., 2013). For the trials, water activity values between 0.861 and 0.906 were observed, while in the standard sample, water activity was 0.873 (Table 1). CAP resulted in a little increase in water activity, but the interaction of water with FOS and SPH mitigate this behavior. Therefore, the water activity was not altered by the substitution of the formulation ingredients (R2 = 0.7496), which resulted in a satisfactory result and reflects directly on the cakes storage.

The instrumental texture attributes are very important in baked goods and can determine product acceptance among consumers. The texture characteristics in cakes are related to the number of gas cells incorporated in the batter after mixing and how the cells expand to form cake volume (Bennion and Bamford 1997). Crumb firmness is the force required to compress a quarter of the two slices.

The crumb firmness was significantly affected (P < 0.001) by the use of carbohydrate substitutes and ranged from 5.70 to 11.10 N for the trial and was 6.69 N for the standard sample (Table 1). Figure 2 shows the contour plots obtained from the predictive models of the texture parameter evaluated. A decrease of firmness was observed with an increase in the amount of FOS (β2 = − 0.56) and SPH (β3 = − 0.45 and β33 = − 0.35) in the cakes. The batter is an oil-in-water emulsion which during the baking process is converted to a porous semi-solid structure due to starch gelatinization and protein denaturation. The same behavior given by FOS on retarding starch gelatinization on specific volume is applicable on instrumental texture, once a greater volume results in a decrease of firmness. Soy protein can form a high batter viscosity due to its high water retention capacity, thus allowing the entrapment of carbon dioxide released by the baking powder chemical reaction (Ronda et al. 2011).

The instrumental color analysis (Table 1) of the crumb performed on the slices of the pound cakes was significantly affected by the substitution of carbohydrates. The lightness (L*) and parameters a* and b* were affected statistically (P = 0.002 for L*, P < 0.001 for b* and P = 0.003 for b*). Although the crumb instrumental color does not undergo the Maillard reaction, it is still affected by the ingredients in the formula. Figures 1 and 2 show the contour plots of predictive models of the color parameters evaluated.

The lightness of the trials was lower than the standard sample (75.17). For the trials from the CCD, the lightness ranged between 53.50 and 71.91 and correspond for the trial with the highest and lowest level of CAP, respectively. It indicates that the use of the fruit in replacement of wheat flour showed the greatest effect on L* value (β1 = − 4.15 and β11 = 0.65), followed by the interaction between the FOS and SPH (β23 = 0.93).

The values for the parameter a* was increased with the increasing of the levels of all the three independent variables and ranged between 4.45 and 8.67 for the trials and were higher than the standard sample (2.04). The CAP showed the greatest influence on the parameter a* (β1 = 1.08) followed by SPH (β3 = 0.29 and β33 = 0.16). for the trials, the parameter b* showed values between 23.95 and 29.27 and for the standard sample, the value was 28.65. The CAP showed the greatest influence on the parameter b* performance (β1 = − 1.03 and β11 = 0.80). The total color difference was observed between 9.90 and 24.69. Although the total color difference was not influenced by the digestible carbohydrates replacers, values greater than 5.00 the observer notices two different colors (Mokrzycki and Tatol 2011).

Figure 2 shows the contour plots of predictive models of the image analyzes for the number and circularity of alveoli since the average size of the alveoli vas not significantly affected. The alveoli formation, such as specific volume and texture, is related to the batter aeration capacity and gas bubbles expansion during cakes baking. The number of alveoli is a result of the cream stage of fat, sucrose/FOS, eggs, and emulsifier.

SPH showed the best performance (β3 = 7.87 and β33 = 2.00) and affected positively (P = 0.003) the number of alveoli in the slices, which ranged between 100.67 and 134.67 for the trials (Table 1). It is desirable to have a large number of alveoli but with smaller sizes (Souza et al. 2018b). The circularity of alveoli was positively affected (P < 0.001) by SPH (β3 = 0.003) and showed values ranged from 0.761 to 0.795 (Table 1), the closer to 1 is the circularity of the alveoli, more it tends to be a perfect circle. The image analyzes emphasizes the positive effect that SPH had on cake batter and the technological quality characteristics of pound cakes, leading to the conclusion that it is a beneficial ingredient to be used on cake formula and allowing an increase in the use of CAP.

Numerical optimization

Numerical optimization was carried out to identify the overall optimal formula using CAP, FOS and SPH as replacers for wheat flour, sucrose and powdered whole milk, respectively. The significant responses were then analyzed jointly after conferring to the variables an importance level (where 5 was the most important). The goal was to maximize the independent variables and the specific volume and minimize specific gravity and firmness. The instrumental color and image parameters were left in the range. Based on these established parameters it was established that the optimum formulation of pound cake was with the following levels of replacers: 40.98% CAP, 94.94% FOS and 100% SPH, which correspond to 0.45, 1.50 and 1.68 at the codified levels, respectively, as shown in Table 2. The desirability obtained was 93.70%. The experimental value for the validation of each of the responses was compared with those predicted by the mathematical model. The tests were performed in true triplicates and the values are also listed in Table 2. All the mathematical models were validated since the relative deviation was lower than ± 10%.

Proximate composition, caloric value, glycemic index and glycemic load of the pound cakes

The values obtained for the proximate composition of the pound cakes showed the positive changes in replacing the ingredients rich in digestible carbohydrates. Table 3 showed the results obtained for the proximate composition of the standard and the low-carb pound cakes. The levels of moisture, proteins and lipids were not affected by the innovative ingredients used in the low carb pound cake.

Table 3.

Results for proximate composition and sensory analysis for standard sample and low carb pound cake

| Component/attribute | Standard pound cake | Low car pound cake | Difference in percentage |

|---|---|---|---|

| Proximate composition | |||

| Moisture content* | 24.51 ± 0.10% ns | 24.49 ± 0.86% ns | Nd |

| Protein* | 9.67 ± 0.74% ns | 9.55 ± 1.14% ns | Nd |

| Lipids* | 21.84 ± 0.23% ns | 18.79 ± 1.89% ns | Nd |

| Ashes* | 0.88 ± 0.04% | 1.10 ± 0.04% | + 25.00% |

| Starch* | 20.37 ± 0.40% | 11.62 ± 0.32% | − 42.96% |

| Reducing sugar* | 2.27 ± 0.19% | 2.86 ± 0.30% | + 25.99% |

| Non-reducing sugar* | 17.74 ± 2.20% | 5.01 ± 0.12% | − 71.76% |

| Total dietary fiber*♠ | 2.73 ± 0.57% | 26.58 ± 2.60% | + 800.37% |

| Total calories value | 180.38 kcal | 142.64 kcal♣ | − 20.92% |

| Sensory analysis scores | |||

| Appearance♥ | 7.96 ± 0.78 | 7.10 ± 1.25 | − 10.87% |

| Color♥ | 7.95 ± 0.86 | 7.28 ± 1.27 | − 8.46% |

| Aroma♥ | 7.50 ± 1.27 | 6.60 ± 1.56 | − 12.00% |

| Taste♥ | 7.36 ± 1.20 | 5.47 ± 1.88 | − 25.62% |

| Texture♥ | 7.51 ± 1.22 | 6.31 ± 1.93 | − 16.01% |

| Overall impression♥ | 7.53 ± 1.01 | 6.17 ± 1.69 | − 18.01% |

| Acceptability index♥♠ | 84.82 ± 2.63% | 72.08 ± 3.97% | − 26.28% |

| Sweetness♥ | 0.26 ± 0.90 | − 1.22 ± 1.09 | − 569.23% |

| Purchase intention♥ | 3.95 ± 0.84 | 2.91 ± 1.12 | − 15.02% |

ns not significant difference between samples was observed (P > 0.05); nd not determined because no significant difference was observed between samples

*Means of 3 replicates ± standard deviation; ♠standard deviation calculated by error propagation; ♣total calories value was calculated by 1 portion (50 g of cake); ***Means of 104 replicates ± standard deviation

The starch, sugar (reducing and non-reducing) and digestible carbohydrates contents of low carb pound cake decreased 42.96, 60.67 and 51.73% respectively, in comparison to the standard sample (P < 0.05). Therefore, the product developed with the optimal formulation could be correctly referred to as a low-carb pound cake. The Brazilian ANVISA (Brazilian Health Regulatory Agency), by the Resolution RDC n° 54, established that the product macronutrient content must be reduced in at least 25% to have a nutritional claim like low-carb.

Another point that should be highlighted in conferring a favorable nutritional claim is the 9.74-fold increase in total dietary fiber content of the low carb pound cake. The fiber added to this sample comes from both CAP and FOS. The non-usual edible parts (seeds and peel) of custard apple were used along with pulp to increase not only the product dietary fiber but also the bioactive compounds and minerals (Can-Cauich et al. 2017). FOS is a functional ingredient with a prebiotic recognized claim often applied as a sugar replacer. FOS is classified as soluble dietary fiber and can be used due to its nutritional advantages and technological properties (Ishwarya and Prabhasankar 2013). The total calories value of the standard pound cake was 180.38 kcal per portion (1 portion of cake correspond to 50 g). The low carb pound cake had a 20.92% reduction on the calorie value with a total of 142.64 kcal per portion.

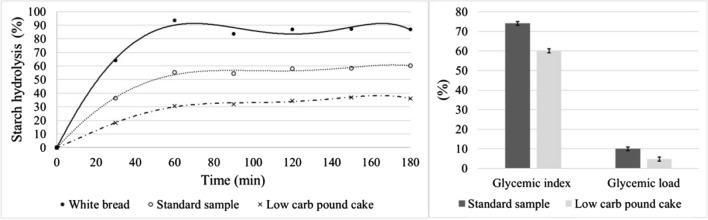

The starch hydrolysis started fast for both samples, but the low carb pound cake was a little slower and at a lower rate (Fig. 3). After about 40 min the hydrolysis rate decreased. The standard pound cake showed a 62.60 ± 2.11% hydrolysis index leading to a high glycemic index (74.08 ± 1.16%) and a moderate glycemic load (14.96 ± 0.16%). The low carb pound cake had a 37.10 ± 0.79% hydrolysis index, which resulted in a moderate glycemic index (60.08 ± 0.43%) and a low glycemic load (5.85 ± 0.03%) (Atkinson et al. 2008). The replacement of wheat flour (rich in starch), sucrose (rich in sugars – glucose and frutose) and powdered milk (source of lactose) by the CAP, FOS and SPH (respectively) led to the reduction of digestible carbohydrates and the glycemic index and glycemic load (P < 0.05). The higher dietary fiber content of the low carb pond cake could be impairing the enzymatic reaction in the starch hydrolysis. The increase of dietary fibers is a valuable approach to modulate digestive enzyme activity and therefore, the glucose levels in the blood (Salgado-Cruz et al. 2017).

Fig. 3.

Starch hydrolysis curves (at left) and glycemic index and glycemic load (at right) for standard sample and low carb pound cake

Sensory evaluation

Wheat flour is important to obtain a good batter viscosity and an ideal cake crumb structure. Studies point out to alteration on the physicochemical properties of cakes when the wheat flour is replaced, mainly due to changes in the protein and starch contents (Guadarrama-Lezama et al. 2016; Mau et al. 2017; Marchetti et al. 2018). Sucrose and milk provide sweetness and take part in the transformations in the cake crust color and physical structure during baking. The cream formed by the mixture of sucrose, fat, eggs and emulsifier is responsible for the batter aeration and cake texture after baking. Therefore, the ingredients rich in carbohydrates from the pound cake standard formulation play an important role in the baking process (Wilderjans et al. 2013). They affect characteristics that set the consumer's acceptability for the product. The results of cake evaluation indicate that the reduction of the carbohydrates has a remarkable effect on the consumer's acceptability (Table 3).

The results of the two cake samples were different for appearance, color, aroma, taste and overall impression assessed by the 1 to 9-point hedonic scale according to the t-Student (P < 0.05). The appearance appreciation ranged between 4 (dislike slightly) to 9 (like extremely) for the standard cake and 3 (dislike moderately) to 9 (like extremely) for the low carb pound cake. The color evaluation for standard pound cake ranged between 4 (dislike slightly) and 9 (like extremely), while for the low carb pound cake the variations were between 3 (dislike moderately) and 9 (like extremely). The pound cakes appearance and color are strongly correlated and the differences between the standard and the low carb pound cake may be due to the darker color of the low carb cake, which resulted from the addition of CAP and SPH. The increase in reducing sugar content of the low carb pound cake (25.99%) can also affect the browning caused by the Maillard reaction.

The aroma appreciation of the low carb pound cake was lower than the standard one. The aroma markers of the cake are influenced by cake formulation, and sugar content is one of the components of interest involved in the formation of these products after baking (Cepeda-Vázquez et al. 2017). The aroma scores ranged between 3 (dislike moderately) and 9 (like extremely) on the hedonic scale. For the low carb pound cake, the variation ranged from 2 (dislike very much) to 9 (like extremely).

The last three sensory characteristics (taste, texture and overall impression) had the worst effect on the consumer’s evaluation. This may be due to the sucrose replacement by FOS that could have impaired the sweetness of the cakes because the increase of the fructose chain decreases the sweetening power of FOS (Ganaie et al. 2013). However, the acceptability index of both samples was satisfactory since the values were 72.08 ± 3.97% for the low-carb and 84.82 ± 2.63% for the standard pound cake. The lower acceptance rate of the optimized point compared to the standard sample can be associated with the sensory memory of untrained judges, who are used to consuming cakes with a higher sugar contente.

Regarding their sweetness level, the evaluation of the samples ranged between − 2 (moderately less sweet than ideal) and 4 (extremely more sweet than ideal) for the standard cake. Most of the consumers (62.26%) classified the standard pound cake as ideally sweet (0). The judges ranged from − 4 (extremely less sweet than ideal) to 1 (slightly more sweet than ideal) for the low carb pound cake. Most judges (37.74%) classified the low carb pound cake as slightly less sweet than ideal (− 1). This data supports the results found for the acceptance index of the low carb pound cake which indicates that FOS could have impaired the sweetness of these cakes. FOS has a sweetening power relative to sucrose of 0.3–0.6 (Ishwarya and Prabhasankar 2013).

The test that evaluated the consumer's intention to purchase, both samples ranged from “I would certainly buy it” to “I would certainly not buy it”. The majority of the consumers said that they probably would buy the standard pound cake (49.06%) and was not sure (33.96%) if they would buy or not the low carb pound cake (data not presented, but obtained in the counting of the evaluation forms completed by the judges). This result could be improved through the use of sweeteners, favoring the perception of sweetness, without increasing the sugar content in low carb pound cake.

The aroma, texture, overall impression, sweetness and intention to purchase the product indicated that the consumers probably are used to eat a pound cake with the regular amount of sugars. Therefore, we think that the consumer's taste memory was decisive to the lower acceptance index for the low carb pound cake. We believe that the insertion of a low carb pound cake must be through a slow and gradual process, in a way that the consumers could acquire the eating habit of this kind of product. A low carb pound cake has a nutritional appeal and can be attractive for the health of the consumers.

Conclusion

Response surface methodology was a useful tool in the optimization of the formulation of a low carb pound cake using CAP, FOA and SPH as replacers to wheat flour, sucrose and milk, respectively. The percentage of ingredients substitution affected the specific gravity of the batter, cakes specific volume, crumb firmness, parameters L*, a* and b* of instrumental color, and number and circularity of the alveoli of cakes slices. The model equations developed can be used for predicting the quality of the low carb pound cake. The optimum formulation of low carb pound cake was obtained with 40.98% of CAP, 94.94% of FOS and 100% of SPH through a 93.70% of desirability and resulted in a nutritionally enhanced low carb pound cake, mainly due to the reduction of 60.67% in digestible carbohydrates. Although the low carb pound cake was rated lower than the standard pound cake by the panelists, the product developed was a low carb pound cake with a moderate glycemic index and low glycemic load with a satisfactory acceptability index by the sensory analysis.

Supplementary Information

Below is the link to the electronic supplementary material.

Acknowledgements

The authors would like to thank Federal University of Jequitinhonha and Mucuri Valleys (UFVJM) and the Institute of Science and Technology (ICT) for the institutional support.

Author contributions

ARDS: Investigation, formal analysis, methodology, software, validation, writing-original draft preparation. MS: Conceptualization, resources, methodology, software, validation, writing- reviewing, supervision.

Funding

This research work was funded by grants from the National Council for Scientific and Technological Development (Universal project, protocol 424938/2016–2) and Coordination for the Improvement of Higher Education Personnel (CAPES, financial code 001).

Declarations

Conflict of interest

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Ethical approval

This study was approved by the Ethics Committee of the Federal University of Jequitinhonha and Mucuri, under decision number CAAE 88198918.4.0000.5108. The project was registered at the Ministry of Agriculture, Cattle and Supplying under number A56B32D.

Footnotes

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

References

- AACCI . Approved methods of the American association of cereal chemists. 11. Saint Paul: American Association of Cereal Chemists International; 2010. [Google Scholar]

- AOAC . Official methods of analysis of AOAC international. 21. Gaithersburg: Association of Official Analysis Chemists International; 2019. [Google Scholar]

- Atkinson F, Foster-Powell K, Brand-Miller J. International tables of glycemic index and glycemic load values. Diabetes Care. 2008;31:2281–2283. doi: 10.2337/dc08-1239. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Bennion EB, Bamford GST. The technology of cake making. London: Blackie; 1997. [Google Scholar]

- Bornet FRJ. Oligosaccharides. In: McCleary B, Prosky P, editors. Advanced dietary fibre technology. Hoboken: Blackwell; 2008. pp. 453–524. [Google Scholar]

- Brouns F. WHO guideline: “sugars intake for adults and children” raises some question marks. Agro Food Ind Hi Tec. 2015;26:34–36. [Google Scholar]

- Can-Cauich CA, Sauri-Duch E, Betancur-Ancona D, Chel-Guerrero L, González-Aguilar GA, Cuevas-Glory LF, Pérez-Pacheco E, Moo-Huchin VM. Tropical fruit peel powders as functional ingredients: evaluation of their bioactive compounds and antioxidant activity. J Funct Foods. 2017;37:501–506. [Google Scholar]

- Capriles VD, Guerra-Matias AC, Arêas JAG. In vitro indicator of the glycemic response to foods as a tool for diet prescriptions and evaluation. Rev Nutr. 2009;22:549–557. [Google Scholar]

- Carocho M, Morales P, Ferreira ICFR. Sweeteners as food additives in the XXI century: a review of what is known, and what is to come. Food Chem Toxicol. 2017;107:302–317. doi: 10.1016/j.fct.2017.06.046. [DOI] [PubMed] [Google Scholar]

- Cepeda-Vázquez M, Rega B, Descharles N, Camel V. How ingredients influence furan and aroma generation in sponge cake. Food Chem. 2017;245:1025–1033. doi: 10.1016/j.foodchem.2017.11.069. [DOI] [PubMed] [Google Scholar]

- De la Hera E, Ruiz-París E, Oliete B, Gómez M. Studies of the quality of cakes made with wheat-lentil composite flours. LWT Food Sci Technol. 2012;49:48–54. [Google Scholar]

- Derringer G, Suich R. Simultaneous optimization of several response variables. J Qual Technol. 1980;12:214–219. [Google Scholar]

- Dhen N, Román L, Rejeb I, Martínez MM, Garogouri M, Gómez M. Particle size distribution of soy flour affecting the quality of enriched gluten-free cakes. LWT Food Sci Technol. 2016;66:179–185. [Google Scholar]

- Felisberto MHF, Wahanik AL, Gomes-Ruffi CR, Clerici MTPS, Chang YK, Steel CJ. Use of chia (Salvia hispanica L.) mucilage gel to reduce fat in pound cakes. LWT Food Sci Technol. 2015;63:1049–1055. [Google Scholar]

- Ganaie MA, Dehariya K, Gupta US. Optimization of process parameters of biocatalyst for transformation of sucrose to fructooligosaccharides. Indo Am J Pharm Res. 2013;3:4138–4148. [Google Scholar]

- Goñi I, Garcia-Alonso A, Saura-Calixto F. A starch hydrolysis procedure to estimate glycemic index. Nutr Res. 1997;17:427–437. [Google Scholar]

- Guadarrama-Lezama AY, Carrillo-Navas H, Pérez-Alonso C, et al. Thermal and rheological properties of sponge cake batters and texture and microstructural characteristics of sponge cake made with native corn starch in partial or total replacement of wheat flour. LWT Food Sci Technol. 2016;70:46–54. [Google Scholar]

- Ishwarya PS, Prabhasankar P. Fructooligosaccharide–retention during baking and its influence on biscuit quality. Food Biosci. 2013;4:68–80. [Google Scholar]

- ISI – International Starch Institute (1999) Determination of reducing power and DE by Lane and Eynon's method. (1999). http://www.starch.dk/isi/methods/27DE.htm. Accessed 02 June 2019

- Kemp SE, Hort J, Hollowood T. Descriptive analysis in sensory evaluation. Hoboken: Wiley-Blackwell; 2018. [Google Scholar]

- Lambrecht MA, Deleu LJ, Rombouts I, Delcour JA. Heat-induced network formation between proteins of different sources in model systems, wheat-based noodles and pound cakes. Food Hydrocolloid. 2018;79:352–370. [Google Scholar]

- Majzoobi M, Ghiasi F, Habibi M, Hedayati S, Farahnaky A. Influence of soy protein isolate on the quality of batter and sponge cake. J Food Process Pres. 2014;38:1164–1170. [Google Scholar]

- Marchetti L, Califano AN, Andrés SC. Partial replacement of wheat flour by pecan nut expeller meal on bakery products. Effect on Muffins Quality Lwt. 2018;95:85–91. [Google Scholar]

- Martin B, Golden E, Egan JM, Mattson MP, Maudsley S. Reduced energy intake: the secret to a long and healthy life? IBS J Sci. 2007;2:35–39. [PMC free article] [PubMed] [Google Scholar]

- Mau JL, Lee CC, Chen YP, Lin SD. Physicochemical, antioxidant and sensory characteristics of chiffon cake prepared with black rice as replacement for wheat flour. LWT Food Sci Technol. 2017;75:434–439. [Google Scholar]

- Merril AL, Watt BK. Energy value of foods: basis and derivation. Washington: U.S. Dept. of Agriculture; 1973. [Google Scholar]

- Mokrzycki WS, Tatol M. Color difference ΔE–a survey. Mach Graph vis. 2011;20:383–411. [Google Scholar]

- Orsi DC, Carvalho VS, Nishi ACF, Damiani C, Asquieri ER. Use of sugar apple, atemoya and soursop for technological development of jams: chemical and sensorial composition. Cienc Agrotec. 2012;36:560–566. [Google Scholar]

- Pandey KR, Naik SR, Vakil B. Probiotics, prebiotics and synbiotics-a review. J Food Sci Technol. 2015;52:7577–7587. doi: 10.1007/s13197-015-1921-1. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Ronda F, Oliete B, Gómez M, Caballero PA, Pando V. Rheological study of layer cake batters made with soybean protein isolate and different starch sources. J Food Eng. 2011;102:272–277. [Google Scholar]

- Sahagún M, Bravo Á, Báscones G, Gómez M. Influence of protein source on the characteristics of gluten-free layer cakes. LWT Food Sci Technol. 2018;94:50–56. doi: 10.1007/s13197-018-3339-z. [DOI] [PMC free article] [PubMed] [Google Scholar]

- Salgado-Cruz MDP, Ramírez-Miranda M, Díaz-Ramírez M. Microstructural characterization and glycemic index evaluation of pita bread enriched with chia mucilage. Food Hydrocolloids. 2017;69:141–149. [Google Scholar]

- Santos JL, Parada J, Santos JL. Interactions among starch, lipids, and proteins in foods: microstructure control for glycemic response modulation. Crit Rev Food Sci. 2015;56:2362–2369. doi: 10.1080/10408398.2013.840260. [DOI] [PubMed] [Google Scholar]

- Schmiele M, Felisberto MHF, Clerici MTPS, Chang YK. Mixolab™ for rheological evaluation of wheat flour partially replaced by soy protein hydrolysate and fructooligosaccharides for bread production. LWT Food Sci Technol. 2017;76:259–269. [Google Scholar]

- Souza NCO, Oliveira LL, Alencar ER, Moreira GP, Leandro ES, Ginani VC, Zandonadi RP. Textural, physical and sensory impacts of the use of green banana puree to replace fat in reduced sugar pound cakes. LWT Food Sci Technol. 2018;89:617–623. [Google Scholar]

- Souza FTC, Santos ER, Silva JC, Valentim IB, Rabelo TCB, Andrade NRF, Silva LKS. Production of nutritious flour from residue custard apple (Annona squamosa L.) for the development of new products. J Food Qual. 2018;2018:1–10. [Google Scholar]

- Tasiguano BL, Villarreal C, Schmiele M, Vernaza MG. Effect of cooking time of pumpkin (Cucurbita maxima) and the addition of glucose oxidase on the increase of resistant starch in loaf bread. Inf Tecnol. 2019;30:167–178. [Google Scholar]

- Wilderjans E, Luyts A, Brijs K, Delcour JA. Ingredient functionality in batter type cake making. Trends Food Sci Tech. 2013;30:6–15. [Google Scholar]

Associated Data

This section collects any data citations, data availability statements, or supplementary materials included in this article.