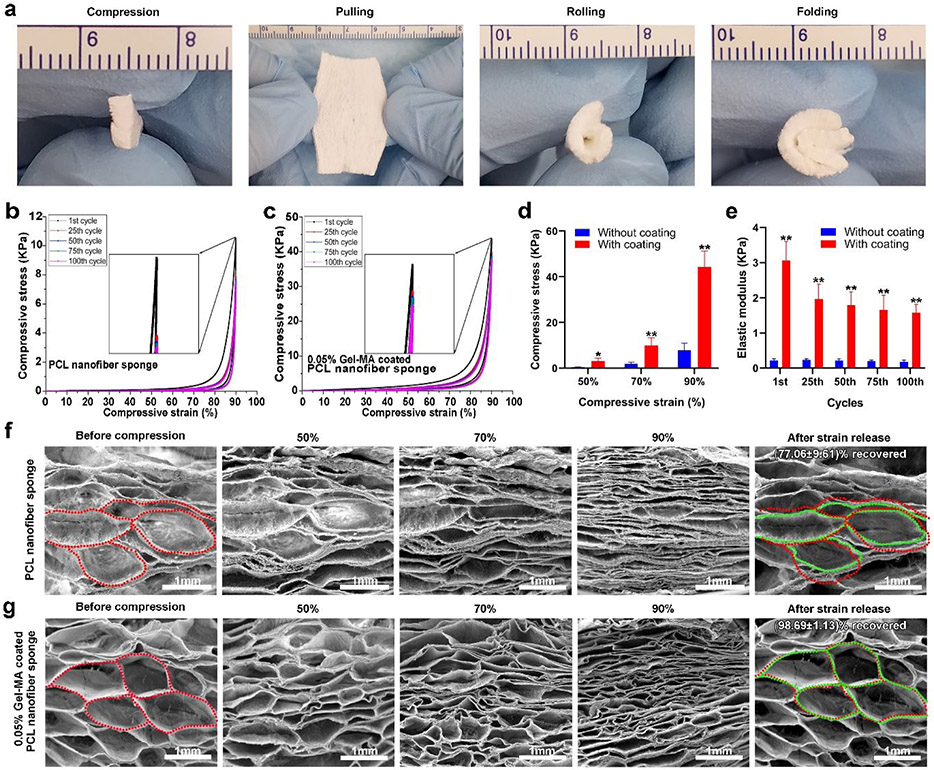

Figure 3.

The superelastic and shape recoverable properties of 0.05% GelMA-coated, 3D expanded PCL nanofiber scaffolds. (a) Photographs showing the flexible properties of 0.05% GelMA-coated, 3D expanded PCL nanofiber scaffolds. Cyclic compressive tests of 3D expanded, PCL nanofiber scaffolds without (b) and with (c) 0.05% GelMA coating in 90% compressive strain (100 cycles). (d) The maximum compressive stress of 3D expanded, PCL nanofiber scaffolds without and with 0.05% GelMA coating in 50%, 70%, and 90% compressive strain. (e) The elastic modulus of 3D expanded, PCL nanofiber scaffolds without and with 0.05% GelMA coating after the 1st, 25th, 50th, 75th, and 100th cyclic compression. SEM images showing the corresponding 3D expanded, PCL nanofiber scaffolds without (f) and with 0.05% GelMA coating (g) before compression, in different compressive strains, and after release of compressive strains. 3D expanded, PCL nanofiber scaffolds without 0.05% GelMA coating failed to completely recover the shape after release of compressive strains. 3D expanded PCL nanofiber scaffolds with 0.05% GelMA coating could fully recover after release of compressive strains. Red dot lines indicate the contours of pores before compression. Green dot lines indicate the original shapes of pores after compression and release of compressive strain.