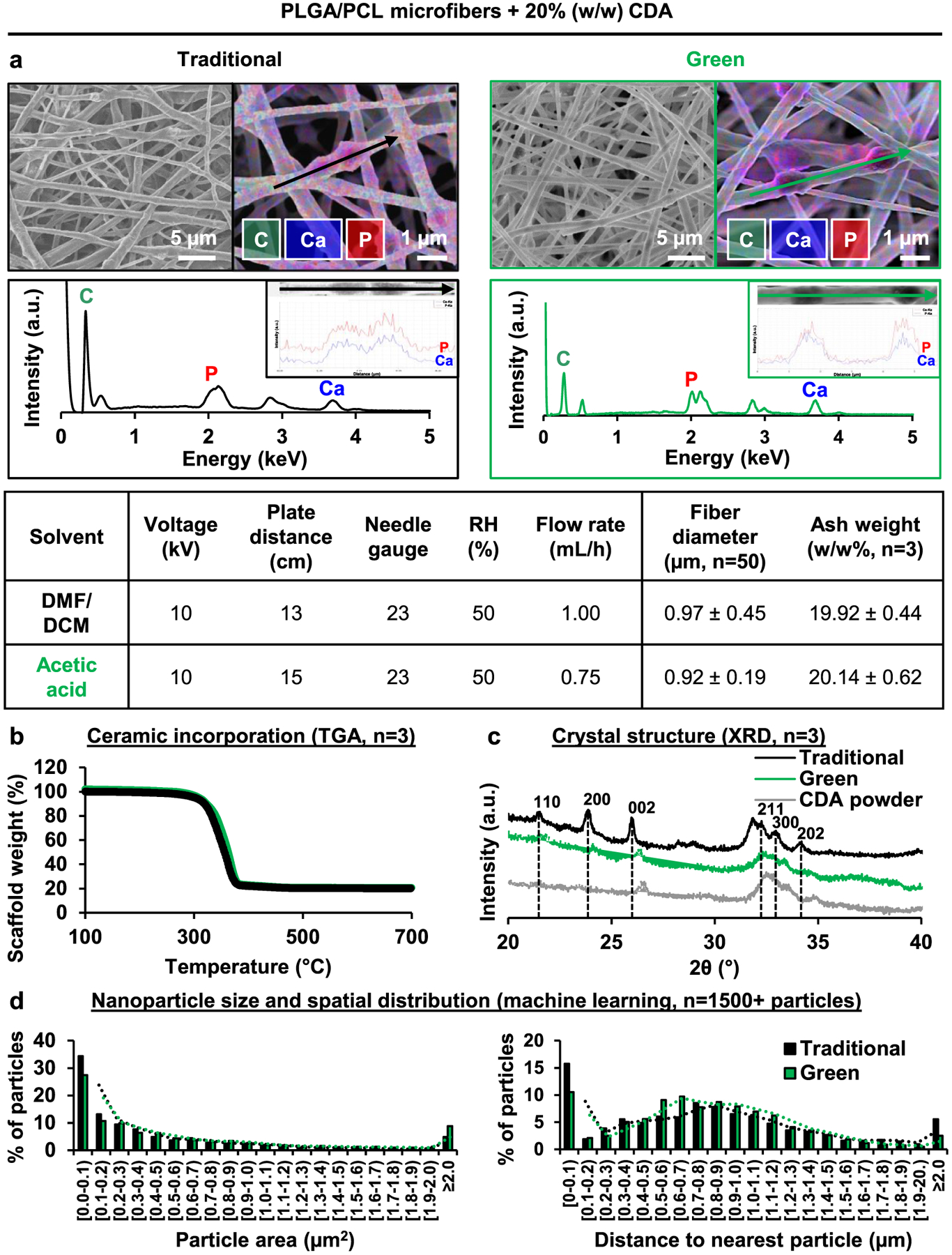

Figure 3.

Green vs. traditional: polymer-ceramic composite fibers. Given the biological significance and wide applicability of composite biomaterials, the formation of biomimetic polymer-ceramic composite fibers is compared with green and traditional electrospinning, incorporating calcium-deficient apatite (CDA) into the PLGA/PCL blend fibers. (a) Under optimized electrospinning conditions (RH = relative humidity), the resultant fiber morphology and diameter are similar between groups (n = 50 fibers/group). Elemental composition of the fibers determined via energy dispersive x-ray analysis (EDXA, n = 10) is also similar, with line profiles along the long fiber axes exhibiting high Ca and P peaks corresponding to CDA particle aggregates. (b) Total ceramic content (20% w/w) is confirmed by thermogravimetric analysis (TGA, n = 3). (c) The characteristic crystal planes for PCL (110, 21.4°; 200, 23.8°) and CDA (002, 26.0°; 211, 32.3°; 300, 33.0°; 202, 34.2°) are detectable in x-ray diffraction (XRD, n = 3). (d) To quantify incorporated ceramic size and distribution, a machine learning algorithm utilizing a multi-layer convolutional neural network (CNN) is built to generate histograms of individual CDA nanoparticle area and nearest distance to the nearest particle (n = 1500+ particles). No difference is found between fabrication methods.